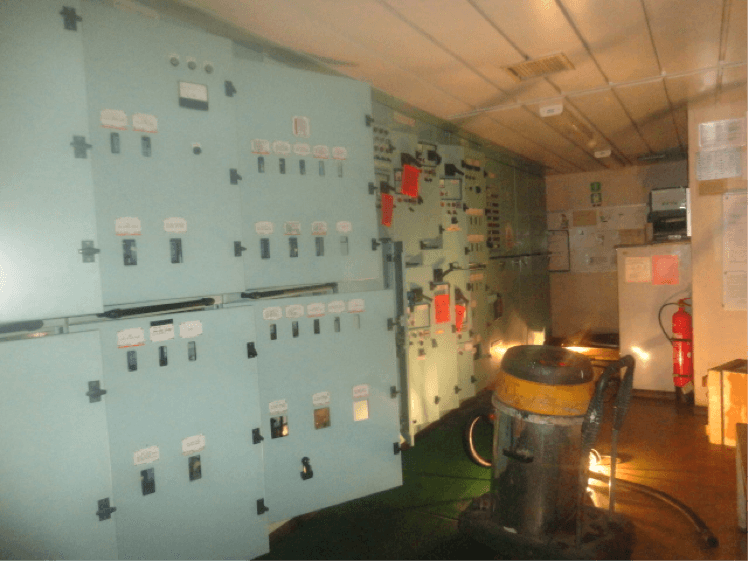

The ship’s engine room is the home to a variety of machinery and systems, which work together to move the ship from one port to another. Engine room professionals have to continuously work amidst such high temperature and pressure systems, which make an extremely hostile working environment.

In spite of taking all the precautions and safety measures while handling engine room machinery systems, accidents are bound of take place in the ship’s engine room. Many of these accidents are extremely dangerous not only to the ship’s properly but also the lives of seafarers. Mentioned below are ten such types of extremely dangerous engine room accidents that occur in ship’s engine room.

1. Crankcase Explosion of Ship’s Engine

Explosion of ship’s crankcase is one of the most dangerous accidents in the ship’s engine room which has led to devastating consequences, including loss of lives in the past.

In the engine crankcase, oil particles are churned into smaller particles of up to 200 micro meters in diameter. These small particles cannot ignite readily even with some naked flame. However, if a hot spot comes in contact with these small particles, it reduces the size of the particles, resulting in the formation of mist, which can be readily ignited with a hot spot.

In the crankcase, all the three elements required for fire are available – lubricating oil (fuel source), air, and heat from a hot spot. Coming together of all these three elements can lead to a major explosion that will not only damage the engine but also take lives of crew members.

Additional Read:

Everything you wanted to know about crank case explosion

How to prevent crankcase explosion on ships?

2. Over-Speeding of Generators

This kind of accidents though rare have occurred in the past, causing heavy damage and loss of lives. When the ship’s generator starts, there are high changes of it to over-speed. If this occurs and the over-speed trip fails to work properly, the high RPM of the generator leads to failure of internal parts. When such situation go out of control, the internal parts such as crank shaft, connecting rod, nut-bolts etc. become loose, get detached, and are thrown away because of the high speed. If crew members do not evacuate the surrounding place in time, the loosen parts can severely harm the crew members.

Additional Read:

10 Major Tests for Overhauling of Ship’s Generator

3. Boiler explosion

Everyone working on ships has heard about boiler explosion as one of the most deadly accidents in the ship’s engine room. A highly pressurized equipment on board ships, boiler has been attached to different kind of accidents as a result of mistakes while operating them. Boiler explosion is one such dangerous accident which is caused because of the following reasons:

– Fuel dripping inside the furnace of the boiler. If the dripping is more and the boiler is fired after an interval, it can lead to blowback and even explosion.

– Misfiring

– Overheating of boiler due to loss of water circulation

– No pre and post purging

Watch: Marine Boiler Operation Explained –

4. Compressor Airline Explosion

Air compressor on ships is also a highly pressurized equipment that can cause deadly accidents. Compressor’s airline explosion is one accident everyone is afraid of. Such explosions usually occurs when during maintenance, the discharge air valve in the line is closed. There is also a common practice among seafarers to shut the discharge valve of the air compressor to minimize air leakage. But when this discharge valve is not opened again while starting the compressor and if the relief valves fail to operate, the airline gets over-pressurized and explodes.

Additional Read:

How to prevent air line bursting?

5. High Pressure Fuel Line Bursting

All high pressurized lines and equipment on board ships are accident prone. The high temperature and pressure fuel line which supplies fuel to the combustion chamber of marine engines can explode if proper maintenance is not carried out. Also, if the lines are not adequately secured, they can burst due to continuous vibrations and friction. Fuel line bursting leads to severe burns, injury and even death of seafarers.

As per regulations, all high pressurized pipes must be jacketed type to avoid chances of fuel leakages and sprays from the pipe joints.

Additional read:

What is water hammer and how to prevent it?

6. High Pressure Steam Leakages

High pressurized steam lines are present in several parts of the ship’s engine room. These high temperature steam lines when burst or crack, lead to leakage of steam at extremely high pressure. Steam burns are extremely dangerous and can even cause instant death. Accidents due to steam leakages can occur because of the following reasons:

Additional Read:

Watch: Engine Room Tour Of Mega Container Ship-

7. Hydraulic High Pressure Components Bursting

Hydraulic high pressure equipment tools are used during overhauling of ship’s machinery and other important systems. If these high pressure systems are not properly tested before use, it can lead to bursting of their high pressurized parts and causing serious injury to the ship’s crew operating them. Some of the major types of hydraulic high pressure accidents are:

8. Turbo Charger Explosion

Turbo charger explosion on ships is caused when turbochargers are not cleaned for a long time. When the parts of turbo charger are not cleaned properly, the carbon deposits do not allow the parts to cool down properly. As a result, when the oil gets into the exhaust side of the turbo charger through the cracks, the heated parts and fuel source form the perfect combination of an explosion.

9. Electrical Shocks

Equipment and cables carrying high electrical power are extremely dangerous for people working on ships. If any kind of maintenance is carried out on such systems without isolating them properly, then there are high chances of getting electrical shocks. Moreover, accidental starting of electrical equipment during maintenance has also been a serious cause of seafarers deaths in the past. Electrical shocks frequently occur on board ships and therefore adequate precautions must be taken to prevent them.

Additional Read:

How to minimize electrical shocks on ships?

10. Accidental CO2 Release

CO2 system is used to release CO2 in the ship’s engine room during fire emergencies only after all the crew has left the engine room. But accidental release of CO2, when the crew members are still present in the engine room, would lead to instant and tragic death of all. Cases of accidental CO2 release in the ship’s engine room has caused several deaths in the past.

Note: While testing engine room CO2 alarm, the CO2 pilot bottles should be properly isolated.

Additional read:

12 things to do before operating CO2 system on ships

Do you know any other type of dangerous accident that can occur in the ship’s engine room?

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.