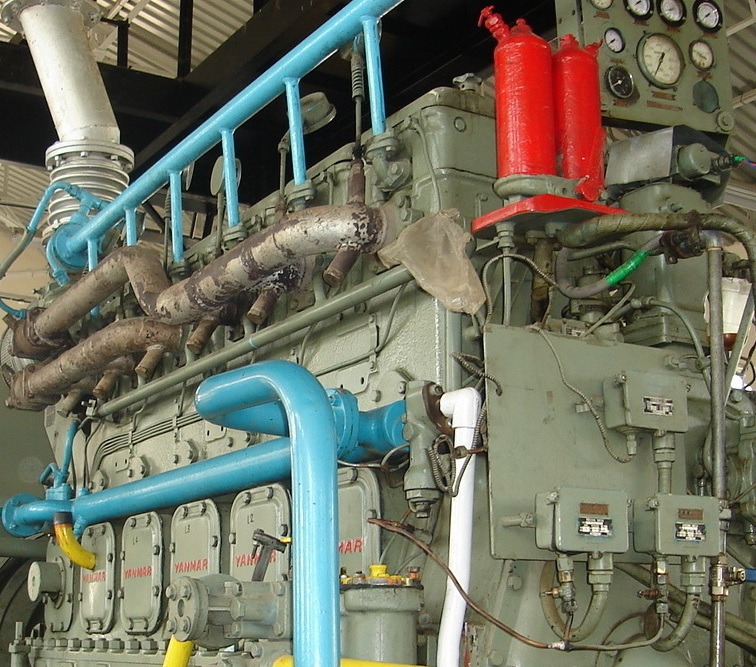

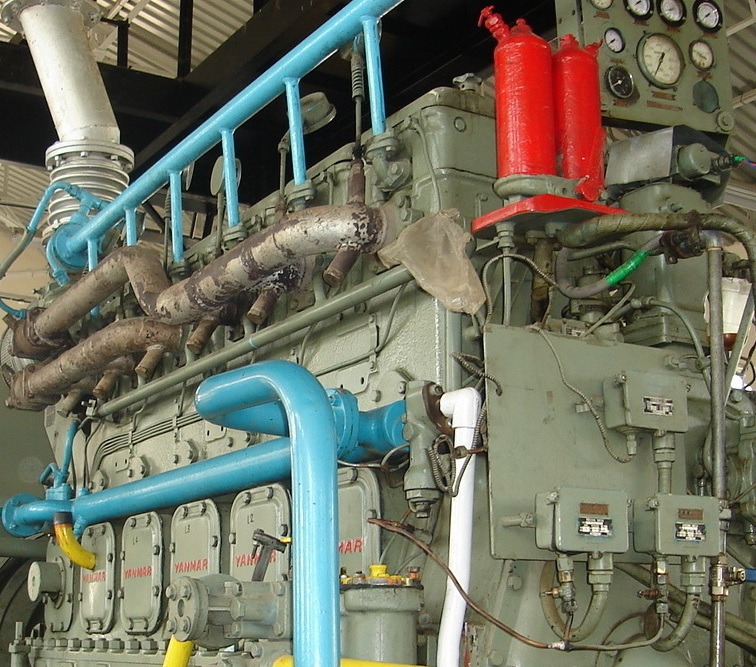

Every time a ship engineer goes on board, he/she has to learn, understand and master the operations and maintenance procedures of the assigned machinery.

An engineer will come across a variety of generator types with different constructional and operational features during the course of his or her career on board. It is therefore important that the engineer knows the basics of a generator machinery system inside-out.

Below is a list of some not-so-commonly-known constructional features of marine generators and some overlooked but important generator procedures that are often not discussed or taught in training sessions or marine engineering books.

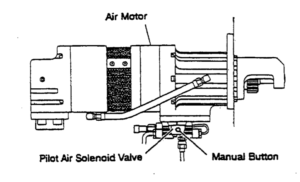

1. Air start motor: Modern marine generators are provided with air start motor which supplies starting air to the combustion chamber. This motor will disengage once the generator RPM reaches approximately 70- 90 RPM depending upon the manufacturing features. In case of emergency or black out, a small switch or knob is provided on top of the motor to start the generator from local.

2. Oil filter cleaning feature: Marine generator is fitted with a duplex oil cleaning filters in the lube oil line. In some generators, these filters come with a quick cleaning feature that can be applied in case of emergency and when the lube oil pressure is low. The changeover handle of the filter is driven in to and fro motion multiple times, which causes cleaning effect on the filter and a sudden rise in the lube oil pressure.

3. Telescopic pipe: Telescopic pipe arrangement is common for supplying lube oil to the piston in two stroke main engine. Some generators (e.g. Daihatsu etc.) are provided with telescopic pipe connected in the piston for lubrication purpose. While overhauling the generator do not forget to remove the telescopic pipe prior to opening the piston.

4. Fuel pump block and floating shaft: This is one unique construction feature of generators like SKL where the fuel pumps are fitted in a separate block (fuel pump block) and connected to the generator by means of a floating shaft for operating the pumps.

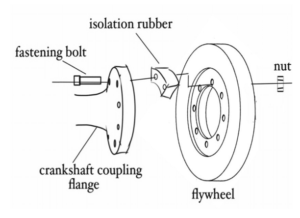

5. Isolation rubber: Some generators with high power output have an arrangement of friction pad coupling to connect the prime mover shaft to the flywheel. No fitted bolts are used for this, instead the rubber pad friction holds the flywheel and prime mover shaft together.

6. Long term shutdown: When the generator needed to be shutdown for a long time (3 or more months) it is wise to use an anti-rust spray on the liner surface and other moving parts of the generator.

7. Indicator cock: While taking up the performance of the generator, the indicator cock is opened. It is important to open all the indicator cocks in full open position. If the indicator cock is half or semi opened, the high velocity hot combustion mixture coming out of it will damage the valve and seat of the cock.

8. Cold Start: In cold condition, if the generator refuses to start in multiple attempts, open the indicator cock and turn the engine with turning gear with lube oil pump running. This will remove the accumulated fuel from the cylinder and avoid any explosion from blow back, which may damage the combustion chamber parts or even lead to accident.

9. Air manifold drain cock: In conditions where the chances of moisture accumulation are high, the air manifold drain cock should be opened up to 1/4th turn at all times even when the generator is running. This will ensure all the water collected due to moisture is drained and damage to the engine cylinders is prevented.

10. Injection Valve: Efficiency of the generator depends mainly on the condition of the injectors, which needs to be pressure tested and overhauled regularly. While replacing the nozzle of the injector, it is very important to loosen the pressure setting screw (located either on the top or on the side of the injector body) before opening the nozzle holding case nut, else it will damage the mating surface of needle, spacer and the straight pin.

It is to note that the above listed features are not present in every marine generator model. Do read the generator manual before performing any kind of maintenance or while operating the generator.

Related Reading:

10 Major Tests For Major Overhauling Of Ship’s Generator

10 Situations When Ship’s Generator Must Be Stopped Immediately

10 Signs That Indicates Ship’s Auxiliary Engine Needs Overhauling

Over to you..

Do you know any other important point that can be added to this list?

Let’s know in the comments below.

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.