Using fixed fire fighting systems is the last resort on board ships to fight a major fire. Majority of the seafarers during their entire career tenure do not get a chance to use the fixed fire fighting system, and in fact secretly wish that they do not ever have to face such situation.

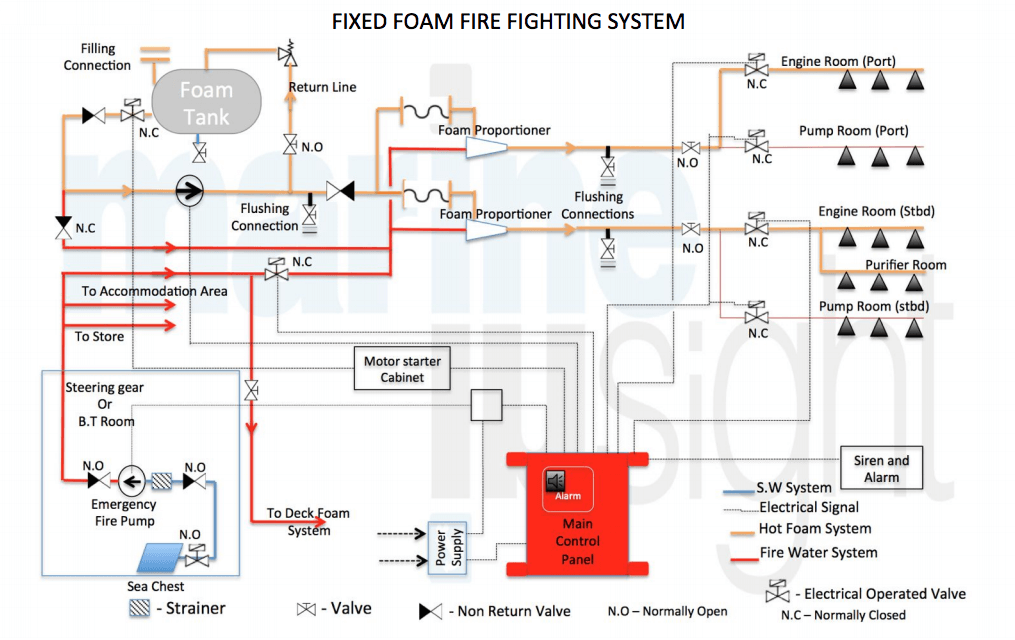

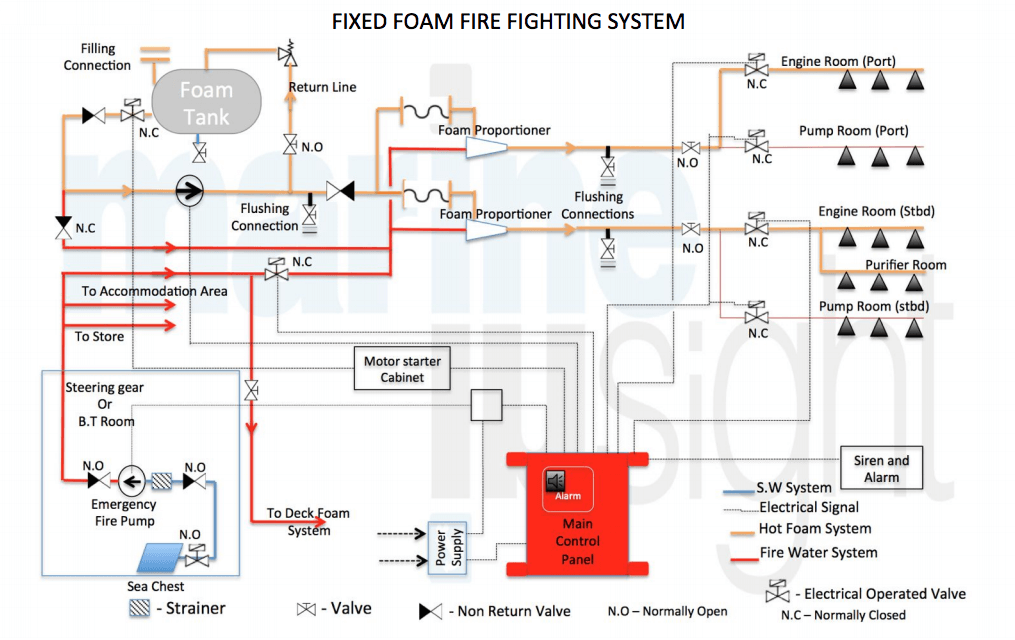

However, an emergency can occur any time and therefore it is important that the ship’s crew is aware of the design and operation of the fixed firefighting system installed on board.

Fixed foam firefighting system non-lethal in nature and can be used even when there are human present inside the fire affected room/room. This makes the initial time duration for application of fire fighting system shorter as compared to the CO2 system which requires evacuation of personnel before operation.

Once the fire is extinguished, the ship’s crew has to make a re-entry in the affected place to assess the damage to the ship’s equipment.

Following common precautions and procedures need to be considered for all fixed fire fighting systems installed on ship:

Following precautions and checks need to carried out once the foam fixed fire fighting system is used for fire extinguishing purpose:

The above points are required to ensure the affected space is checked and cleaned, and the machinery in that space is ready for further usage. The foam system needs to be made normal as soon as possible to ensure it is ready for any other emergency situation in near future.

Note: The above mentioned is not an exhaustive list but mentions all important points for precautions and checks while using fire fighting system. Do you know any other important point that should be added to the list? Let’s know in the comments below.

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.