If you are a marine engineer working on ships, you would know that there is a massive difference between the theoretical knowledge provided in the maritime books and the practical skills that are acquired by getting one’s hands dirty in the engine room. Though there is no substitute to the knowledge that is acquired through years of experience working in the engine room, a marine engineer wouldn’t be able to survive if ignores the bookish knowledge completely.

A ship’s engine room is installed with different types of machinery systems, each requiring specific approach while carrying out maintenance and troubleshooting. It is only through a healthy combination of knowledge and practical skills can a marine engineer understand his machinery inside-out.

So what exactly does it take for a marine engineer to know his machinery systems inside-out?

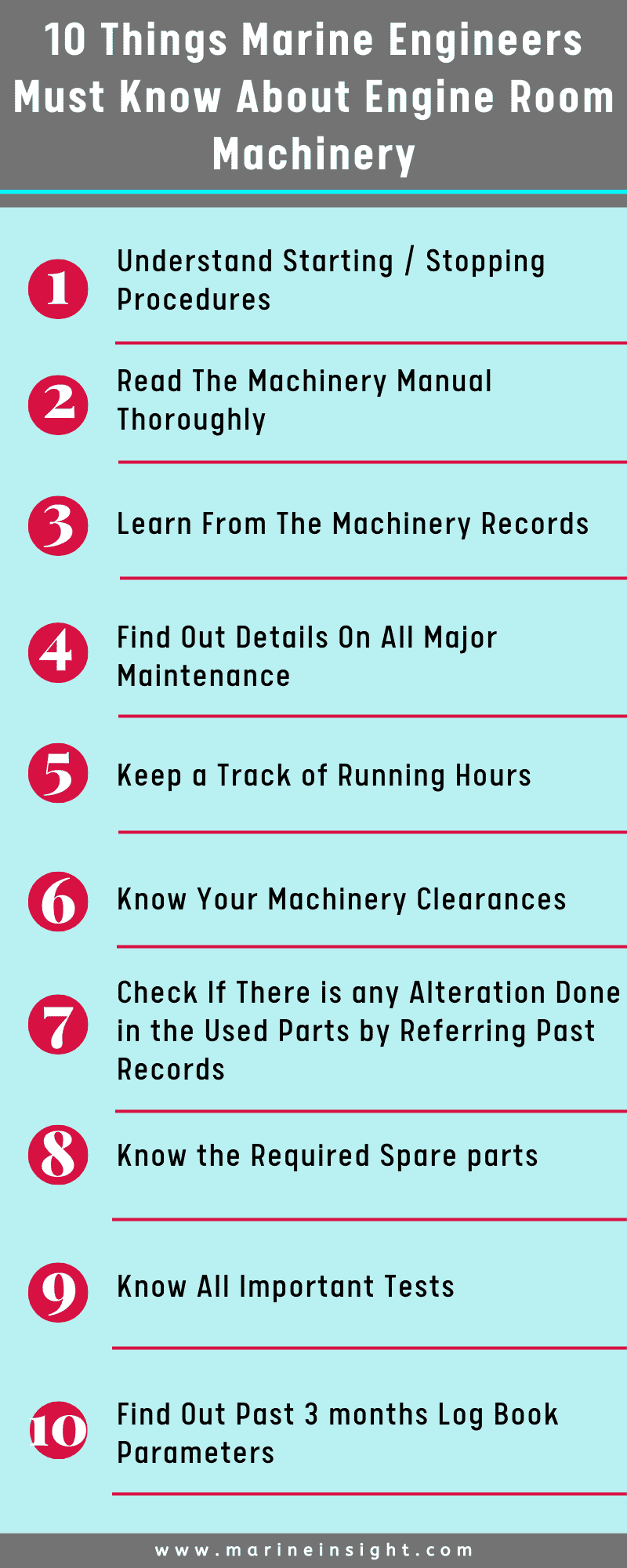

Mentioned below are few key points which can help marine engineers for understanding their machinery and systems in a better way.

Every ship is different and so are its machinery systems. Though the basic type of machinery systems remains the same for all ships, the operating and maintenance procedures would differ according to the manufacturer of the machine and the ship type.

It is imperative for a ship’s engineer to understand the starting and stopping procedures of his machinery extremely well before doing everything else. This can be done by using the operating manual of each machinery system and asking questions to fellow engine room colleagues/seniors. (Most of the times, engineers are afraid to ask seniors or colleagues for help as they feel that it would make them look inexperience and dumb. Though people on board ships have a tendency to judge a person’s knowledge by the kind of questions he or she asks, it is always better to get over such apprehensions and gather as much details about your machinery as possible. Moreover, there are always officers on board who would be more than happy to share their knowledge when asked. It is always better to know everything about your machinery before hand than to regret and slog during breakdown or emergencies.)

Note: The operating manuals would teach the basic steps for starting/stopping a machinery. But it’s only through experience that an engineer will be able to understand how his machinery works, what are their common issues, and how he can troubleshoot them quickly.

As mentioned above, the manual of every machinery is the bible to understanding that particular system. As an engineer, you must know your machinery manual like the “back of your hand”. It’s the knowledge base on which you will be able to build the foundation of your maintenance schedules and troubleshooting techniques. Without knowing the construction/design of your system and understanding how it works, you will be shooting “arrows in dark” while dealing with an emergency situation.

A marine engineer therefore must read, understand, and memorise his machinery manual to the best of this abilities.

Every engine room machinery has a history which should be studied thoroughly by the marine engineers. This history will tell you about the all the things that the machinery has gone through in the past including major accidents, problems, and overhauling operations. Based on these records, a marine engineer will also be able to plan his routine maintenance procedures and prepare the troubleshooting approach with utmost ease.

Go through the records of the past few months to find out when and how did your machinery got stuck or confronted a problem. The data therein would help you to learn a lot about your machine.

Past maintenance reports helps engineers to understand the main problems that the machinery has faced and what are the issues that have been experienced frequently. The maintenance reports would also include all important comments and tips that needs to be considered while handling that particular machinery system. Marine engineers must study the maintenance reports not only to understand the past problems but also to learn how the machinery will behave under different conditions.

Depending on the running hours of the machinery, the ship’s engineer will plan and perform the next maintenance procedure. Keeping a track of the running hours is extremely important to prevent any kind of sudden failure or breakdown of machinery. Marine engineers must properly maintain and monitor the running hours as stated by the manufacturer or the company to ensure smooth running of their machinery systems. They would also help to plan any major maintenance of the machinery in the next scheduled dry dock.

Routine maintenance is an integral part of marine engineers’ duties on board ships. One of the important aspects of the machinery which engineers must be aware of are the different types of clearances. A ship’s engineer must keep a close watch on the clearances of different parts of engine room machinery such as bearing and bumping clearances in compressors, crank pin and piston ring clearances in generator etc. as they are an important part of any planned maintenance system. These data would help to plan out and schedule the next maintenance operation.

Ship’s machinery systems are constantly going through regular maintenance procedures which often involves major repair works. During such procedures some of the machinery parts are to be altered to perform repair jobs. For e.g. whenever any major repair is done on the crank shaft pin of the marine engine (through grinding), the dimensions of the adjoining parts like the shell bearings are also altered. It is therefore important for engineers to look through the past records to find out if any alteration of machinery parts done in order to ensure that the right kind of spare parts are used during any pending or future maintenance or repair work.

A marine engineer must have the knowledge of all the spare parts that are required for his machinery. It is imperative that these spare parts are available in the ship’s inventory especially during sudden break down and while planning machinery overhauling. Go through the manuals to know what all parts will be required to carry out maintenance and repair work. Cross-check the ship’s inventory to keep a track of the number of spare parts left on board ships. Raise a requisition whenever required.

All important engine room machinery and systems have some kind of tests attached to them for their smooth operations. As a ship’s engineer, it is important to understand these tests and learn how are they performed and what are the procedures involved to send the required sample shore. Tests such as boiler water tests, generator lube oil test etc. require engineers to know about their contents, chemicals involved and common impurities found. Learn the purpose and procedures of these tests to ensure smooth running of your machinery.

Log book is one such reference on board that marine engineers have to refer every single day. Apart from this, they must take out time to go through the log book parameters of their machinery, especially from the past three months, in order to understand common problems or any major changes that have taken place in their usual operations. If an engineer is new to the ship, log book is the best and quickest reference which would help to know and understand his machinery system.

Do you know any other important things which marine engineers must consider in order to know their machinery systems extremely well? Let us know in the comments below.

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.