Fuel oil, diesel oil, and lubricating oil tanks are the names of tanks everyone is aware of. But there are several tanks apart from them which also play an important part in the overall working of the ship. Moreover, there are also tanks of which many people are not aware of. In this article we will have a look at some important and some not-so-famous tanks present on the ship.

Hydraulic Oil Tanks

Hydraulic oil tanks for valves

Separate tanks are used to store oil which is used for different valves on the ship. Valves such as ballast valves, fuel valves etc. are remotely operated by hydraulic oil.

Hydraulic oil tanks for Winches

Tanks for hydraulic oil are located outside the engine room to store winches oil.

Hydraulic oil tanks for Steering gear

Steering gear hydraulic oil tank is normally located in the steering room and is used as a storage tank to receive bulk oil.

Water tanks

Fresh water tanks

Fresh water tanks present onboard may be two or more in numbers, depending upon the size of vessel. They are used to store sanitary water for accommodation, engine room and deck use.

Drinking water tank

A separate drinking water tank may be present to store drinkable water received from shore or to store water produced by fresh water generator (F.W.G).

Distilled Feed water tank

A ship’s boiler needs distilled water to produce steam, and therefore water from fresh water generator (F.W.G) is stored in distilled water tank.

Boiler feed water tank

The boiler feed water system consist of a separate tank which receives water from distilled water tank.

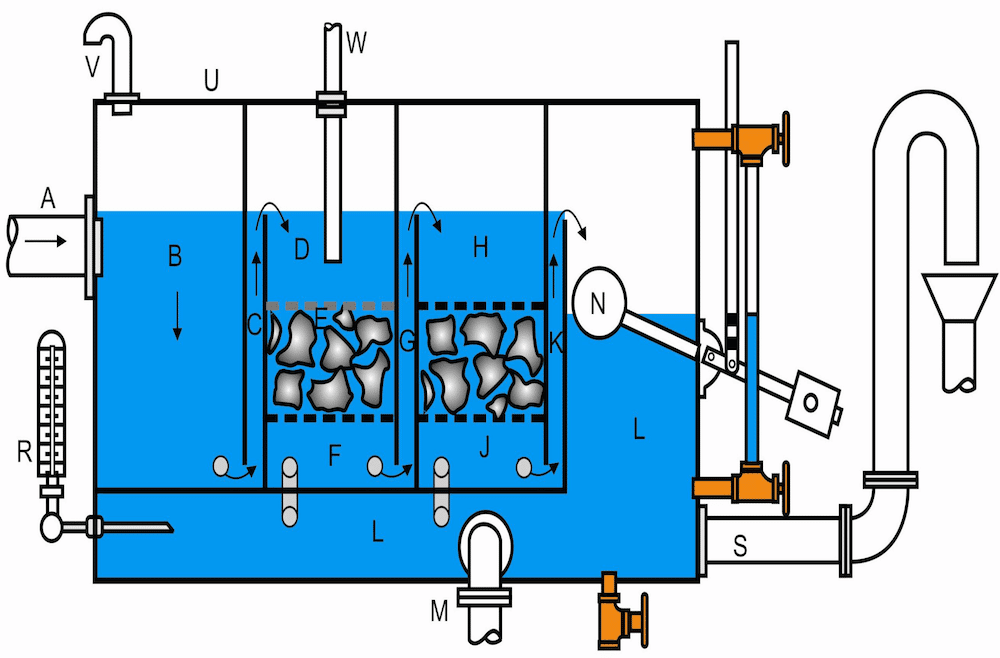

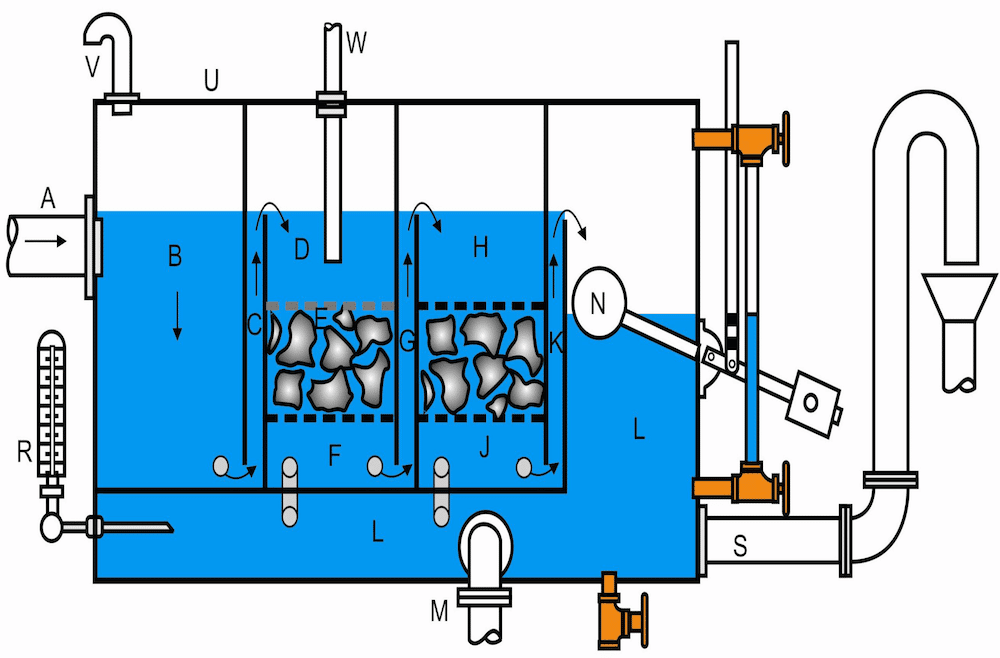

Cascade tank

Cascade tank, also known as hot well, is a part of boiler feed water system. Water is pumped into the cascade tank from the feed water tank. The boiler water is treated in the cascade tank and the return from the steam heating system is also connected to the hot well.

Ballast water tanks

Ballast water tanks are present all over the ship for ballasting and de-ballasting purpose for stabilizing the ship and for acquiring correct draught for port and canal crossing etc. Double bottom tanks are generally located outside the engine room.

Stern tube cooling water tank

This tank is located around the stern tube of the propeller and acts as a cooling media for the same. It can be used as a fresh water water tank of the ship.

Slop tanks

Slop tank in tanker

Slop tanks are present onboard tanker to store oily water mixture from cargo tank washing. The number of slop tanks depends on the Dead weight Tonnage (DWT) of the vessel.

Sludge tank

Located in engine room, this tank is used to store sludge produced after treating fuel or lube oil through purifiers.

Bilge tank

The water and oil leakage in the engine room is collected in bilge wells and this oily water mixture is then transferred to primary bilge tank or bilge holding tank, where the mixture is settled down and then is transferred to secondary bilge tank.

The oily water separator is supplied through secondary or separated bilge tank and a shore connection is also connected to this tank to dispose off all the collected bilge to shore.

Scavenge drain tank

The sludge produced by the main engine in the scavenge area is collected in the small capacity scavenge drain tank.

Oily Water Separator (O.W.S) Sludge tank

When oily water separator operates, it separates oil from water and that oil is collected and discharged into a separate tank known as O.W.S sludge tank.

Other Not-So-Famous yet Important Tanks

Drain tank

The drain tank is located in the engine room. All drip trays and other drains are connected to this tank.

Leak off tank

This is a small tank separately fitted in the main engine and all auxiliary engines to detect any fuel leakage. The tank consists of an orifice and a float. If the leak is very small, it will pass through the orifice; but if leakage increases, the oil will not be able to pass through the orifice and tank level would increase, rising the float and thus giving an alarm.

Stuffing Box Tank

The main engine stuffing box scraps the impure lubricating oil, which is collected in a separate tank known as stuffing box tank.

Stern tube gravity tank

The stern tube system oil is circulated in the system by means of two tanks, lower gravity and upper gravity tanks.

Waste oil tank

The waste oil tank is a separate tank used to collect waste and impure oil produced onboard ship.

Soot collecting tank

When the economiser tube washing is done, the soot water is collected in a soot collecting tank.

Sewage holding tank

The sewage produced from the onboard crew is collected in a common tank known as sewage collecting tank. The sewage plant takes intake from the sewage holding tank.

Expansion tanks

The jacket water system of main engine, auxiliary engine and some times main air compressor are provided with individual expansion to provide provision to compensate change in volume and maintaining positive pressure.

Jacket water drain tank

When any maintenance is to be done on the main engine, the jacket water is drained and collected into the jacket water drain tank.

Rocker arm tank

Many diesel generators are provided with separate rocker arm lubricating oil tank to avoid contamination.

You may also like to read Fresh Water Generator & Ballast Water Management plan

Image Credits:

norherntool

chazsworld

ssmaritime

nauticexpo

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.