Watertight doors are special types of doors found on ships that prevent the ingress of water from one compartment to another during flooding or accidents and therefore act as a safety barrier.

It limits the spread of water inside the vessel. These doors are used onboard in many ships such as in the fore and aft passageways underdeck and in engine room bulkheads leading to shaft tunnels in container vessels, large passenger ships, offshore vessels, oil exploration vessels.

They are used in areas where chances of flooding are high. Areas such as engine room compartments and shaft tunnels and some of such places.

Therefore it is important that crew members are familiar with the system as well as the location of different powered watertight doors aboard ship.

Let us first understand the meaning of watertight and weathertight.

Watertight as defined in SOLAS is: capable of preventing the passage of water in any direction under the head of water likely to occur in intact and damaged conditions.

Weathertight is defined as that in any sea conditions water will not penetrate the ship.

To make it simpler, a watertight door can prevent the passage of water in both directions when subjected to a head of water i.e it can withstand water pressure from both sides. They are designed to withstand continuous submersion and are therefore located below waterline like shaft tunnels, ballast tanks, bow thruster compartments etc. all openings below the waterline has to be watertight.

Weathertight doors, on the other hand, is designed to withstand brief submersion. They are located above the waterline and can withstand the weather condition as found offshore which means from the outside.

In this article, we will briefly explain the function and operational requirements of watertight doors.

Watertight doors are categorized into three types, which govern the operation of the watertight doors.

TYPE A:

This type of doors may be left open and are to be closed only during an emergency.

TYPE B:

This type of watertight doors should be closed and are made to remain open only when personnel are working in the adjacent compartment.

TYPE C:

This type of watertight doors is to be kept closed all the time. It may be opened only for sufficient time when personnel are passing through the door compartment.

TYPE D:

This type of watertight doors is not SOLAS compliant. These doors shall be closed before the voyage commences and shall be kept closed during navigation. These doors cannot be upgraded to another category.

a) When there is restricted visibility.

b) In ports where the port limits off compulsory pilotage limits.

c) Required to be closed when the depth of water is less than 3 times the draught.

d) High traffic density.

e) Other factors when the master feels that the condition is dangerous.

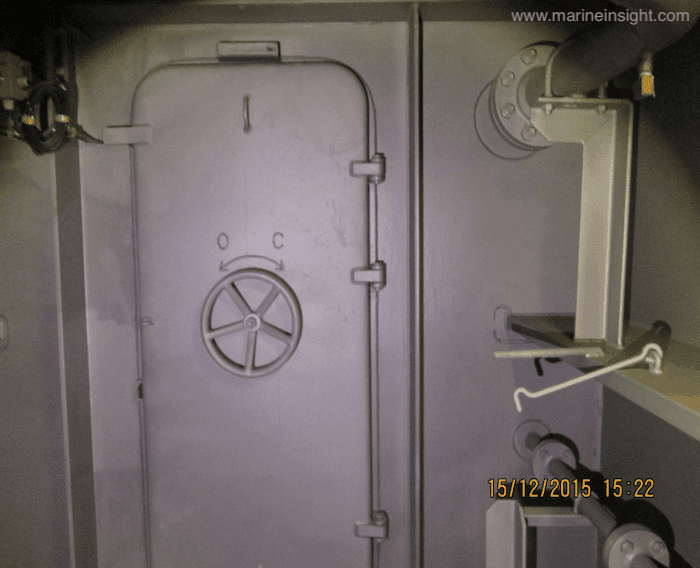

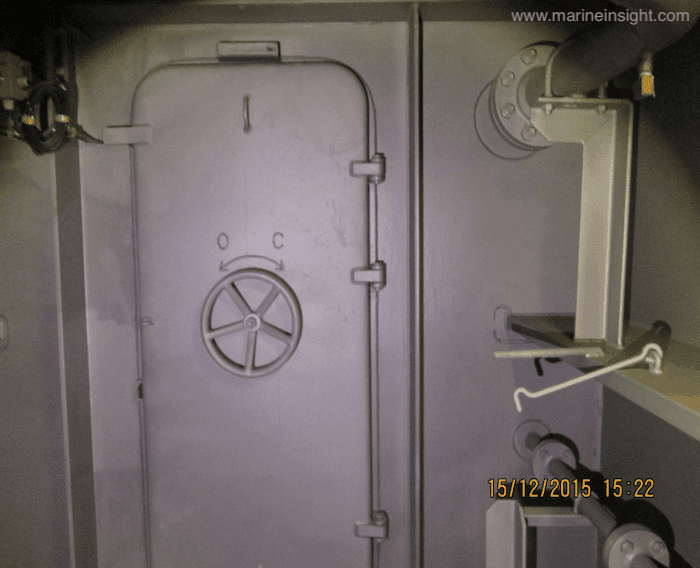

Hinged type: A door having a pivoting motion about one vertical or horizontal edge.

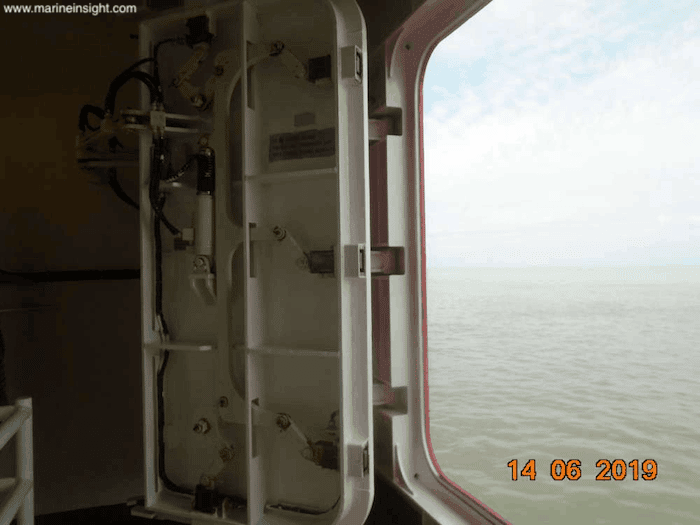

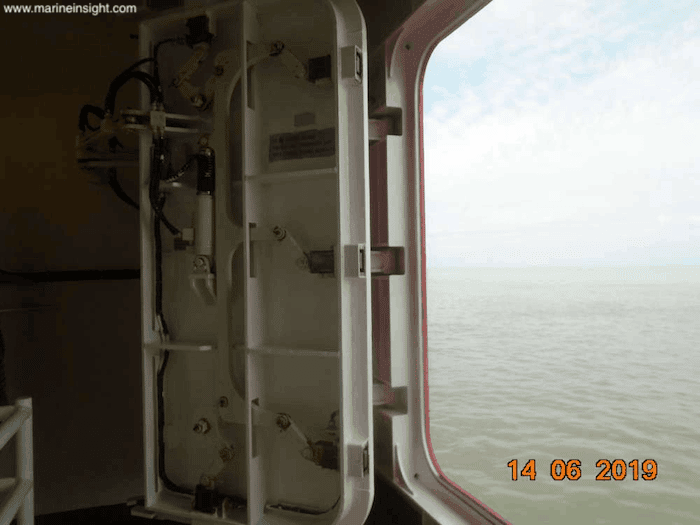

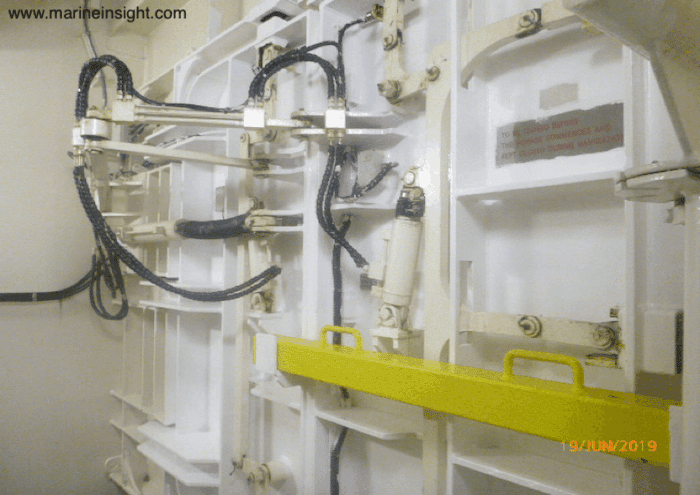

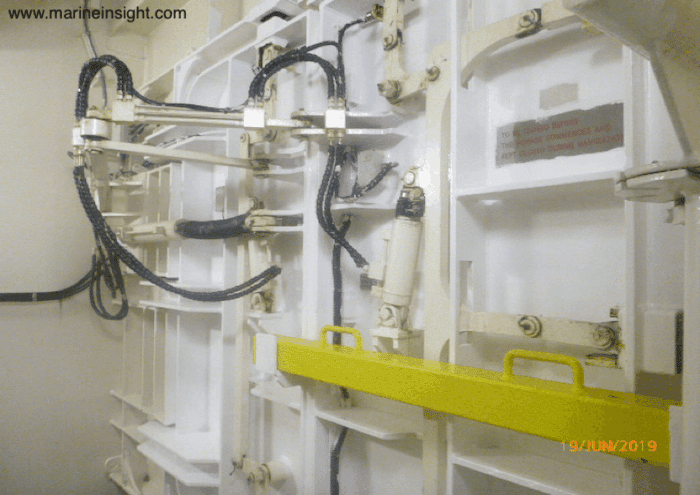

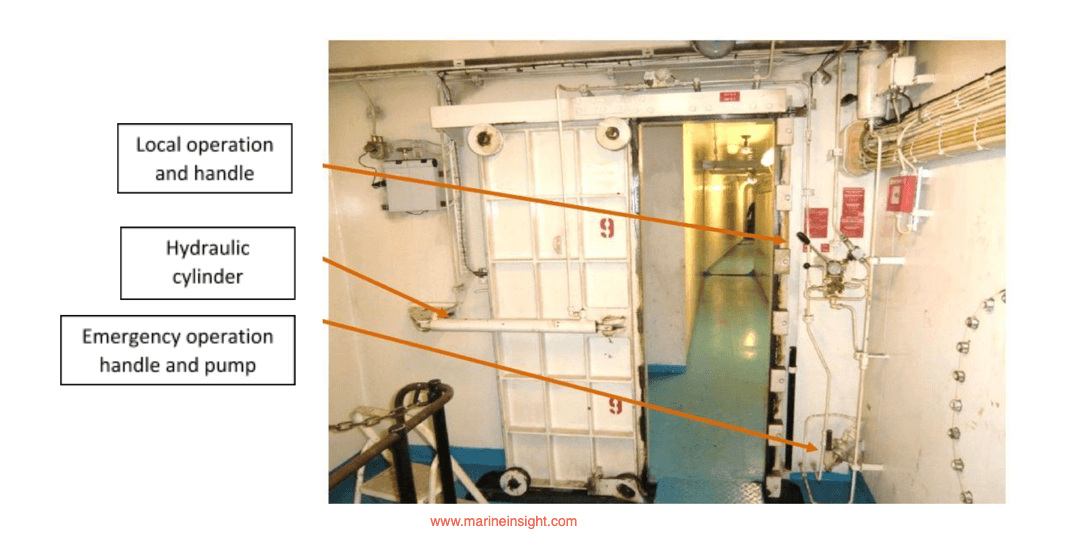

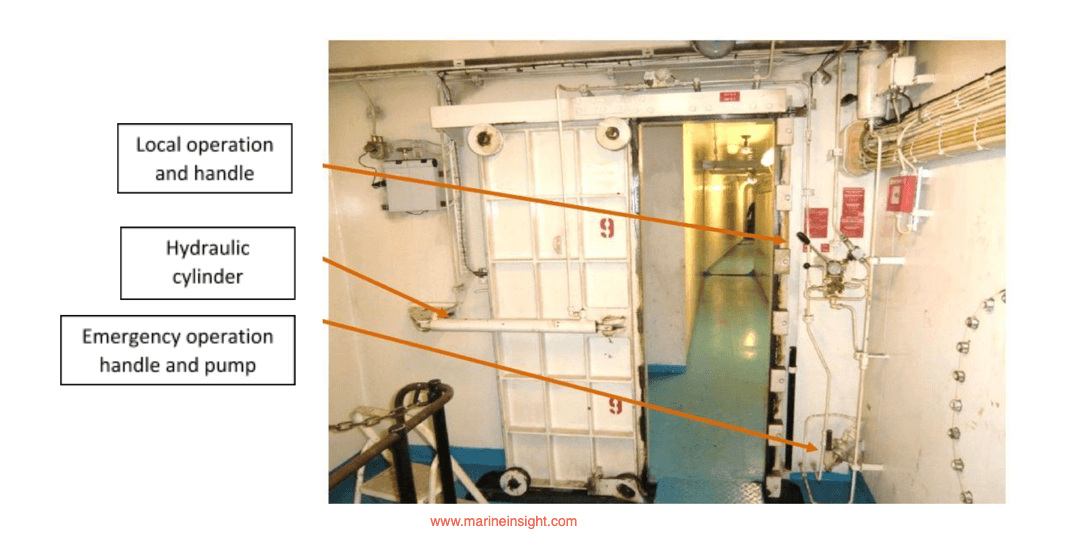

Sliding type: A door having a horizontal or vertical motion generally parallel to the plane of the door powered by hydraulic cylinders or electric motors.

Powered watertight doors are extremely heavy and powerful. If used incorrectly, they can maim or kill. Everyone onboard the ship must clearly understand the associated risks and how to operate them safely.

What can be some of the risks associated with power operated sliding door?

Almost all accidents are avoidable. They are nearly always the result of not following the correct procedures. This is because the door is used so frequently by the crew that they start to oversee the risks or because of poor supervision.

1. Drills for the operation of watertight doors shall take place every week. Also, the doors should be checked before leaving the port.

2. All watertight doors, both hinged and power operated should be operated daily during the rounds.

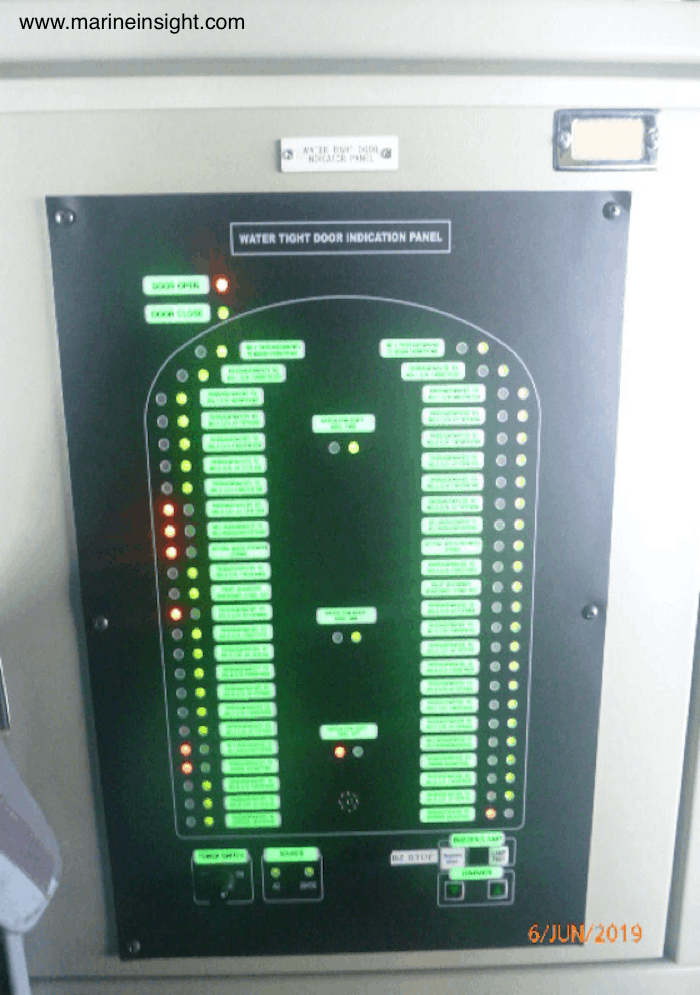

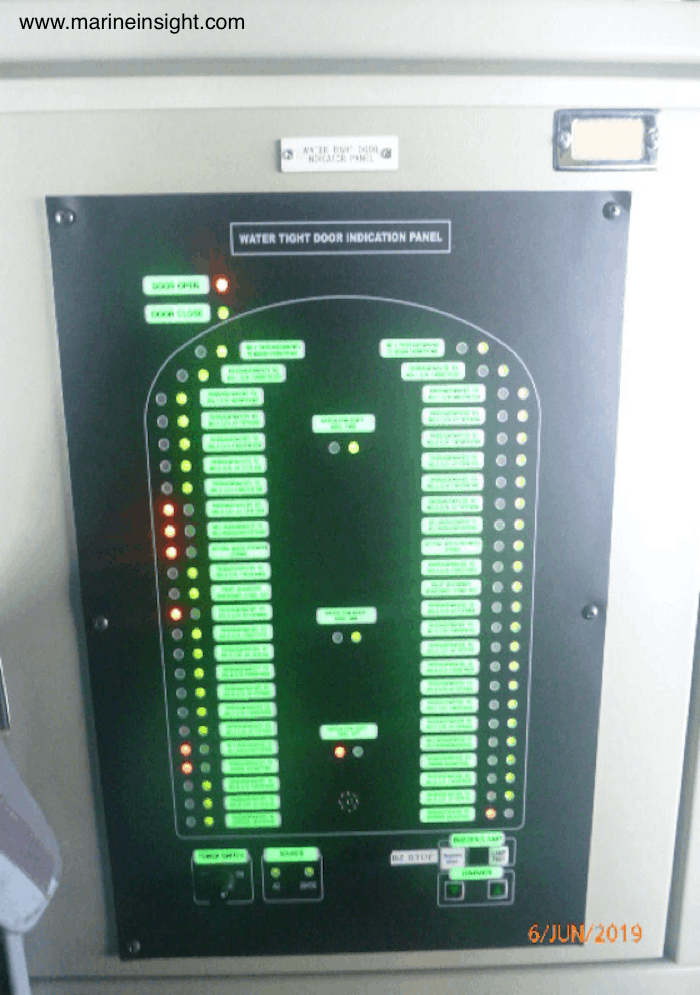

3. The door should be able to operate from both local and remote places. i.e. bridge and ship control centre.

4. If the door is operated from a remote location, there should be an audio and visual alarm during the closing,

5. There should be an indication of both open and close on the remote place of operation.

(As per Solas regulation, SOLAS chapter II-1, watertight doors from regulation 14 to regulation 25)

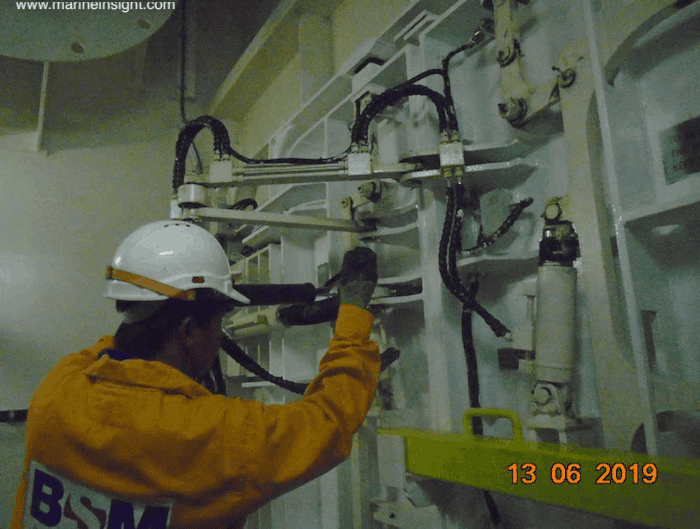

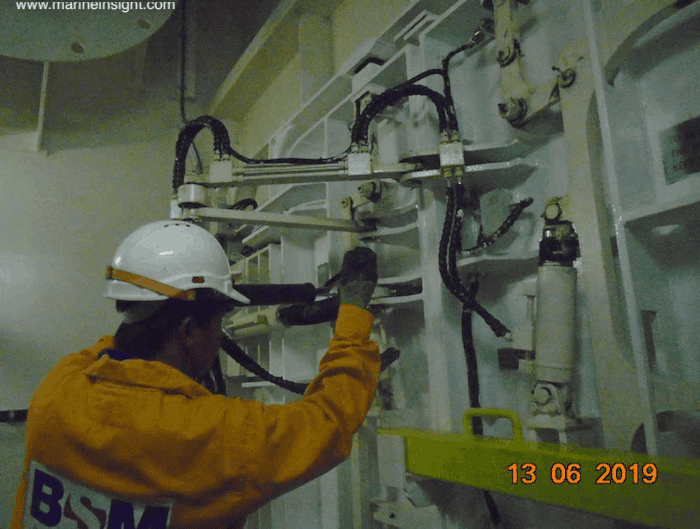

Powered watertight doors can be operated either locally or remotely from the bridge. LOCAL CONTROL is when the doors are both opened or closed using the door’s own controls. It should be noted that when doors are operated using the BRIDGE CONTROL mode, doors can also be opened using the local controls, however, the door will close immediately once the local control lever is released.

1. All the power operated doors must be capable of closing simultaneously from bridge and Ship Control Center (SCC) is not more than 60 seconds when the ship is in an upright condition.

2. The door shall have an approximate uniform rate of closure under power. The closure time, from the time the door begins to close to the time it closes completely, shall be in no case less than 20 seconds or more than 40 seconds with the ship in an upright condition.

3. In case of hand operation of the door, during a power failure, the door must be closed within 90 seconds.

4. Power-operated sliding doors shall be capable of closing with the ship listed to 15 degrees either side.

5. Power-operated sliding doors should be provided with a local audible alarm distinct from any other alarm in that area which shall sound for at least 5 seconds whenever the door is closed remotely but not more than 10 seconds before the door begins to move. The sound should be audible until the door is completely closed.

6. Controls for opening and closing the door should be provided on either side of the door as well as on the central operating console at the bridge. The control handles are located at least 1.6m above the floor on passenger ships.

7. Remote operating positions at the navigation bridge shall have means of visually indicating whether the doors are open or closed. A red light indicates a door is fully open and a green light indicates that the door is fully closed.

8. The direction of movement should be clearly indicated and displayed at all operating positions.

9. There is also a secondary control station, located above the bulkhead deck so that the powered watertight doors can be closed in the event that a fire or flooding prevents someone reaching them to operate the local controls.

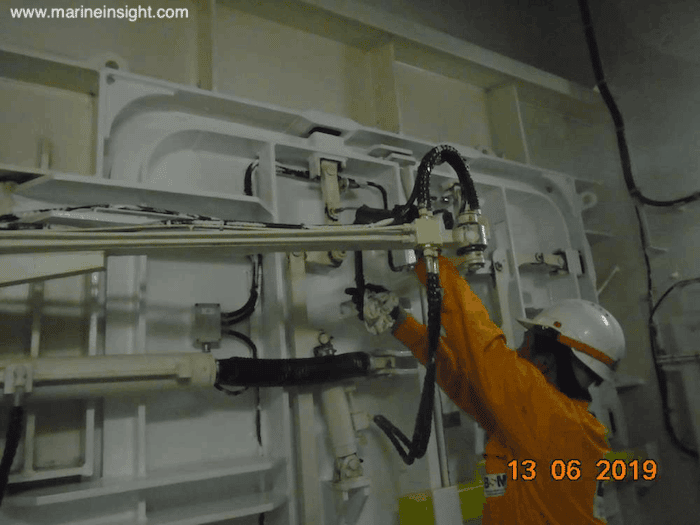

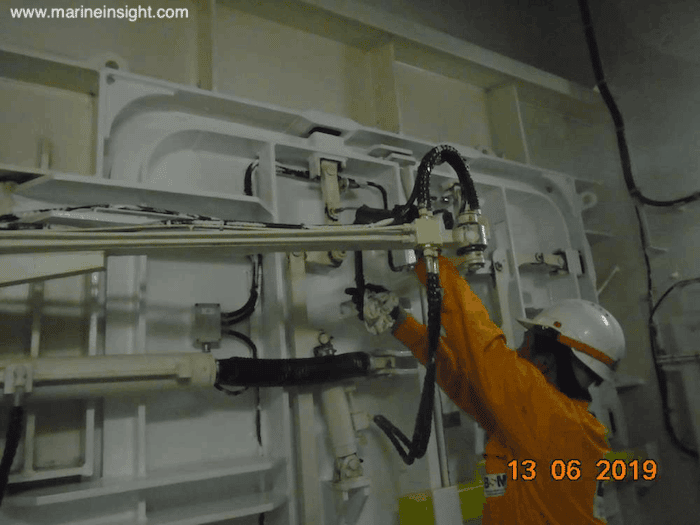

The ship’s planned maintenance system must be followed for carrying out routine inspection and maintenance on watertight doors which should include the correct functioning of the whole system and specifically:

It is also important to stick to the manufacturer’s maintenance guide. Before any maintenance work is carried out, warning notices should be posted.

Failure in the proper maintenance and operation of watertight doors can draw the attention of Port State Control inspectors and can be a cause of vessel detention.

Missing portions of gaskets, leakage of hydraulic oil, faulty alarms, lack of door closed indication in remote operating positions are some deficiencies that have been observed during the inspection.

After all, they are designed to keep the vessel safe and therefore watertight doors should never be neglected. Powered watertight doors under no circumstances should be modified, for example, to disable the alarm or to adjust the speed of operation.

They should be identified as safety critical equipment. Neglecting the importance of watertight doors can have a great impact on the watertight integrity of the ship and have disastrous consequences.

All crew members should, therefore, be made familiar with the operation of the watertight doors onboard and the safety precautions to be adopted. Operation of the watertight doors should be a part of onboard training and drill regime.

Doors should not be left open unless has been advised to do so. Keeping watertight doors closed should always be promoted. The safety rounds must ensure the integrity of the accommodation and watertight areas/ weather tight areas around and in accommodation.

When at sea, it is imperative to check all watertight doors are closed. We must understand and acknowledge that it is for our own good and safety of the ship. Nothing should be done which can jeopardise safety onboard ships.

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of The Marine Learners. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and The Marine Learners do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and The Marine Learners.

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.