The international shore connection is a universal hose connection that is to be provided on all ships as per the IMO SOLAS requirement.

The purpose of the International Shore Coupling is to keep a standby hose attachment to get a connection from shore or from other ships for shipboard firefighting, in case there is a total failure of pumps onboard.

Related Reading: 7 Common Problems Found In Pumps On Board Ships

While using International Shore Connection, the seawater is supplied at a pre-decided pressure and is connected to the ship’s fire main.

This international shore connection flange is generally kept at a convenient and accessible location (Bridge or in Fire locker) of a ship so that in case of an emergency it is readily available and used.

Related Reading: 16 Fire Fighting Appliances And Preventive Measures Present Onboard Ships

The international shore coupling SOLAS requirement under Chapter II-2, regulation 10.2.1.7 says; ships above 500 tons gross tonnage and upwards must have at least one international shore connection.

The international shore connection flange has a standard size and is the same for all the countries and ships to ensure that if the ship faces an emergency out of the home port, firefighting assistance from any port is always available.

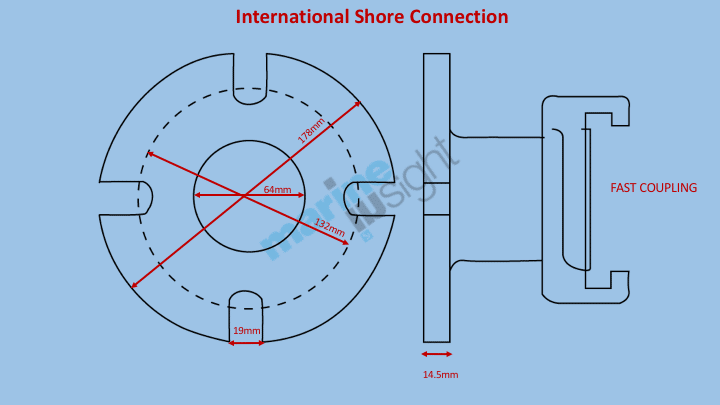

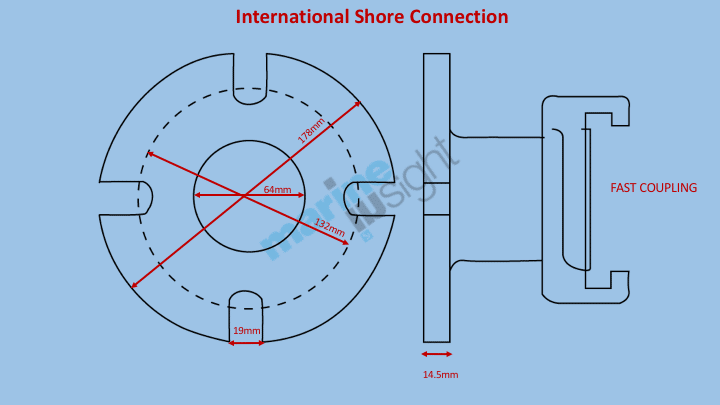

The Dimensions of International Shore Coupling are:

|

Description |

Dimension |

|

Outside Diameter (OD) |

178mm |

|

Inside Diameter (ID) |

64mm |

|

Bolt Circle Diameter (PCD) |

132mm |

|

Slots in Flange |

4 holes 19mm in diameter spaced equidistantly on a bolt circle of above diameter, slotted to flange periphery. |

|

Flange Thickness |

14.5mm minimum |

|

Bolts & Nuts |

4, each of 16mm diameter, 50mm in length |

Related Reading: A Brief Overview of Fire Control Plan On Ship

Basic Requirements for International Shore Connection

All ships, jetties and offshore platforms, likely to require an emergency source of fire water or to provide the same, should have at least one international shore fire connection.

Related Reading: How to identify metals in the engine room?

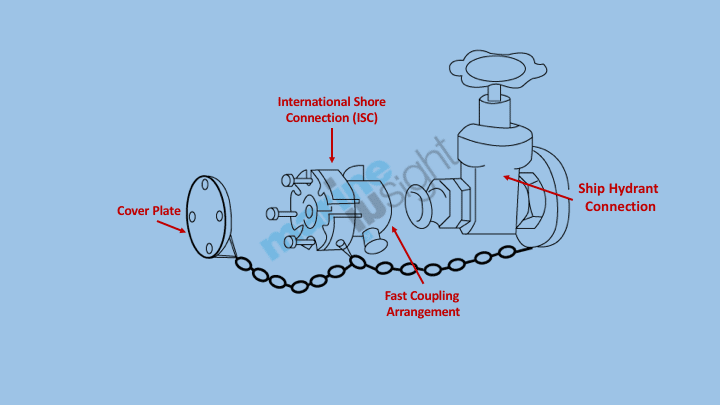

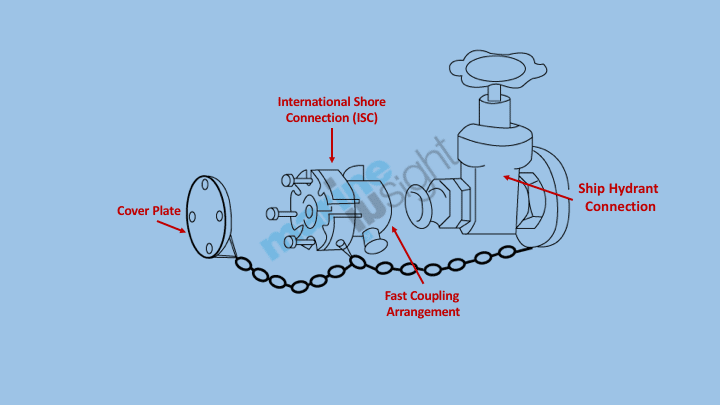

The connection should be made up of steel or other suitable material and shall be designed for 1.0 N/mm2 services. The flange should have a flat surface on one side and another side should be permanently connected or attached to a coupling that can be easily fitted to ships hydrant and hose connection.

The connection should be kept on board with a ready gasket of material that can handle a pressure of 1.0 N/mm2 together with four 16mm bolts, 50 mm in length and eight washers so that the connection can be readily used in case of an emergency situation.

Related Reading: Fighting fire in ship’s cargo hold in port

If the ISC is fixed on the vessel’s fire main, the shore connection should be accessible from either side of the ship and be clearly marked.

A notice should be posted near the ship’s fire main close to the accommodation in English and local language of the ship’s flag, indicating the connection’s location and the maximum working pressure of the piping system which the port must acknowledge and supply.

Related Reading: How to avoid fire in ship’s accommodation area?

The velocity of water supplied by the port or another ship to the affected ship shall not exceed 5 m/s in the firewater distribution network.

The fitting and joints must be suitable for a working pressure of at least 10.5 bar.

Important Points to consider related to ISC:

Related Reading: 10 Things that Should Be Included In Ship’s Planned Maintenance System

Related Read: The importance of fire drills on ship

Image Credit/Reference: Marine Auxillary Machinery By H.D Mc George

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of The Marine Learners. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and The Marine Learners do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and The Marine Learners.

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.