Transportation of goods by sea is the most cost-efficient way of moving cargo from point A to point B. More than 90% of world trade is carried by sea. Since the financial crisis of 2008, our shipping industry has been facing head-wind and rough seas. Cost cutting is the new mantra for shipping companies to remain afloat and set sail during these turbulent times. Gone are days when cost cutting was seen as something to improve profit; we are in the time where cost-cutting is seen as a necessity to just survive!

As deck officers on board ships, we are required to carry out various jobs and undertake huge responsibilities while working in some of the most hostile environments in the world. Our employability is no more only determined by our skills as prudent sailors but also by our capabilities to contribute to cost-cutting and reduction in the operational cost of running a ship. It is a simple chain, we help our owner to cut cost, our owners remain profitable and we remain employed.

Let’s see how as navigating officers, we can achieve this by following simple ways.

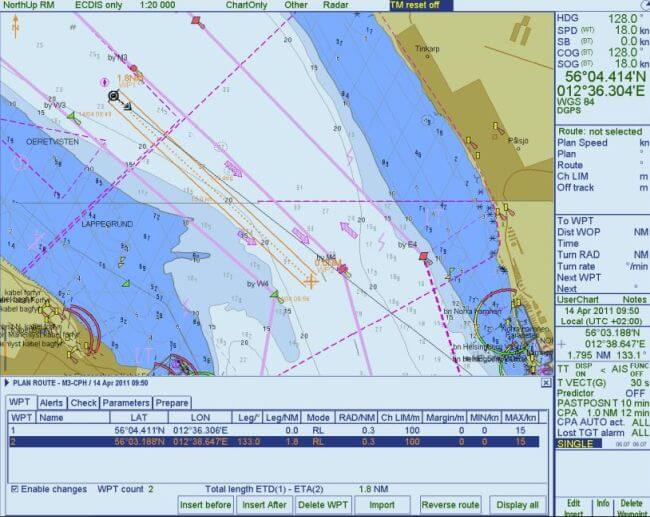

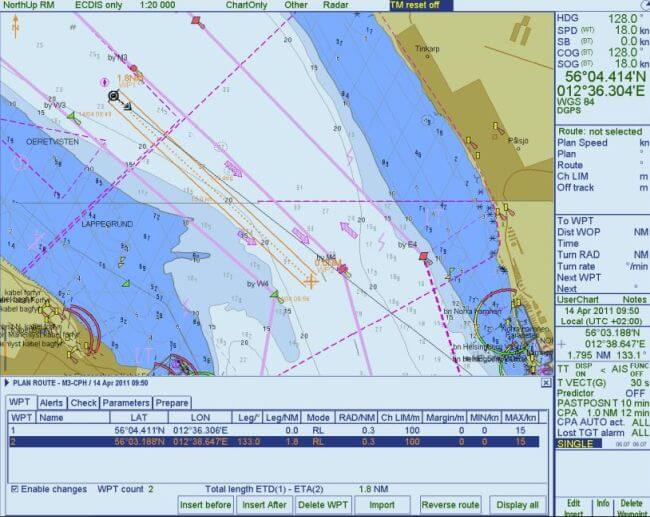

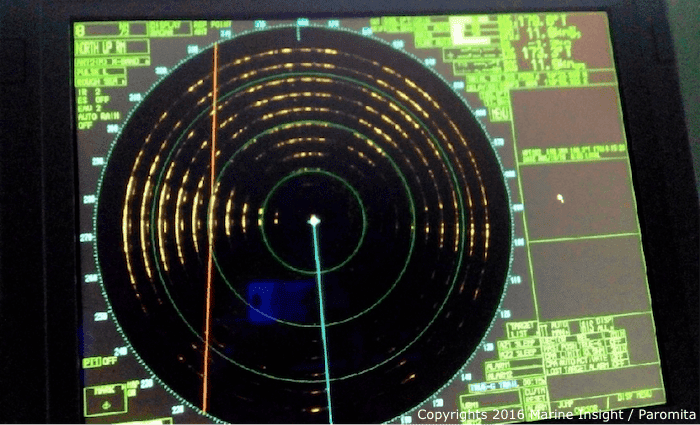

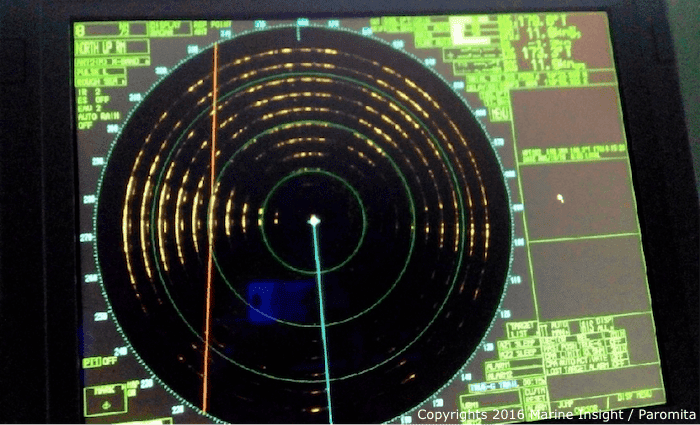

The main contributing factor with respect to running cost of a ship is consumption of bunkers. It is generally the duty of the second officer on a ship to plan passage from point A to point B, while safety accounts the main contributing factor in determining which route to be taken, it is also important to consider a route which consumes the least amount of bunkers. For this, one has to take into account not only distance but also expected weather patterns, current, tidal streams etc.

Proper planning is thus required before commencement of passage which includes but not limited only to information from weather charts, wave height data, proximity to tropical revolving storms (TRS) or temperate latitude depressions (TLD), wind force and ocean currents etc. Thus by taking all these into consideration, the best possible passage should be taken, which not only is primarily safe but also saves bunkers.

The math is simple. If one can save about 50nm worth of distance in an average voyage of a week, with present bunker rates a vessel can save about $1600 (considering a typical handymax type of a vessel). If the same result can be achieved throughout the year then it means huge saving for the company.

The most expensive bunkers are MGO (Marine Gasoil) and LSMGO (Low Sulphur Marine Gasoil). During port operations, when the ship is either loading or discharging her cargo, these bunkers are used for running auxiliary engines, inert gas generators, marine boilers etc. With strict environmental regulations coming into force, more and more ports do not allow the use of HFO (Heavy Fuel Oil) while the ship is operating in port. This has increased the ship’s running cost while at the port.

Thus as officers responsible for safe cargo operation, it is also our duty to help reduce any wastage of these expensive bunkers so that port operational costs can be reduced. This will not only add to the profitability of our owners but also help reduce CO2 and other emissions.

Following points should be kept in mind by ship officers while in port:

1. Deck and engine officers should be in constant communication so that unnecessary running of machinery can be stopped for saving bunkers. It is common to witness that duty engineers are unaware that a machinery, say power pack or inert gas generator (on oil tankers) or for that matter cranes on a geared bulk carrier are running idle. It is the responsibility of duty officer to promptly inform the duty engineer about the status of running machinery so that these can be stopped if running idle.

2. Proper use of machinery can also reduce the number of bunkers consumed. For example, the proper combination of pumps and pumping techniques as per manufacturer instructions, can reduce the load on power packs and thus reduce bunker consumption. One more example is properly adjusting capacity valve in the inert gas system so that minimum or no inert gas is vented out and only the volume required for discharging cargo is produced and introduced into the cargo tanks. The same principle can be applied to various other kinds of vessels as well.

3. Maintenance of machinery can improve its performance thus reducing the number of bunkers consumed. Proper maintenance of pumps and associated equipment as per manufacturer’s advice can improve efficiency thus reducing bunker consumption. Same is applicable to deck cranes or any other machinery involved in cargo operation.

Another major contributor to the cost of running the ship is unexpected machinery or equipment failure. These unexpected failures are also a major safety hazard and the reason for various accidents occurring around the year on ships. With hectic onboard operations, proper maintenance of machinery or equipment is becoming difficult day by day, leading to these failures. Such things not only delay the ship but at times are very costly to repair, resulting in huge cost and set back to owners, not to mention the loss of reputation in this ever increasingly competitive industry.

In order to prevent unexpected failure of machinery or equipment, PMS (Planned Maintenance System) should be followed religiously. Special importance should be given to critical equipment or machinery. If at all due to hectic routine, maintenance is not possible, same is to be notified to the company on urgent basis. All necessary aspects such as spares, special permission from authorities or arranging technicians at a convenient port etc. should be taken so that maintenance is carried out on time. It would not be wrong to say an apt proverb here that “The more we sweat in peace the less we bleed in war”.

Technology is changing very fast. One has to keep upgrading and updating with the latest technology. When it comes to our industry we can use the latest technology to reduce the overall cost of running the ship. For example, while requesting for stores one should ask for energy efficient LED lights rather than regular CFL (though there is some limitation restricting its usage on the bridge). Also, use of latest software for managing PMS (Planned Maintenance System) and inventory management can help in reducing wastage. Upgrading to a digital publication such as ADP (Admiralty Digital Products), e-NPs etc. can also help in reducing logistical and other charges associated with regular paper publications.

Check out The Marine Learners’s Digital Books here.

With respect to marine communication, upgrading to the latest equipment and selecting the cheapest service provider can reduce communication costs. Use of compressing software such as win zip etc. can also help in reducing communication costs as charges are generally billed on the amount of MB (megabytes) consumed. Use of latest software for radio accounting can help owners segregate the costs with charterers and other third party using ship’s communication equipment.

The next big thing, which contributes to running cost of ships, is consumption of stores and spares. It is not uncommon for ships to order wrong stores or spares costing owners lot of money. It is thus very important that proper inventory of all stores and spares are maintained onboard. This will reduce the chances of ordering items which are already onboard. It will also reduce the chances of ordering wrong stores or spares.

Inventory management should be a part of PMS (Planned Maintenance System) so that it is not neglected. Time invested in maintaining inventory will in long run be very beneficial in reducing unnecessary wastage with respect to wrong stores or spares procurement.

As discussed above stores and spares accounts for a major chunk in the operational cost of running of ships. Although procurement of stores or spares cost a lot, logistics also account a major part of overall costing in arranging of stores or spares for ships. As many of us are aware that there are ports were these logistical costs are comparatively less, for example, Amsterdam, Rotterdam, Singapore, Fujairah, Houston Etc. It is thus logical to ask for the maximum amount of required spares and stores at these ports, thus reducing their overall logistical charges and helping owners save money.

Judicial use of stores and spares is also very important. One should not misuse or be reckless while using stores or spares. Especially when it comes to critical spares one should be mindful of using them. A sense of belongingness is what a prudent officer should have before using any stores or spares.

Asking for technicians without going through thorough troubleshooting also cost huge on owner’s pocket. Simple problems can be sorted out just by reading manuals properly. One should also ask for technical support from office for fault finding if unable to do so on own. It reflects really bad on ship’s officers if say a technician solves a problem by replacing just a fuse or restarting a system and then charge company thousands of dollars for his service!

Good communication between team members is very important for any organization to succeed. Same applies when it comes to working on board ship. If regular safety and maintenance committee meetings are held which involves people from all departments then all the requirements can be streamed down and then only forwarded to the company. This will reduce chances of duplication and additional requisitions for stores or spares. In addition to this, many issues can be solved with the expertise available onboard ship itself, thus reducing any spares or services required to be hired from shore.

Related reading:

How team meeting help to improve safety and efficiency of ships?

6 Ways to improve interpersonal relationships between seafarers

In times like ours with severe financial crunches engulfing companies, it is very important to educate our juniors and crew members about the importance of inculcating qualities such as proper usage of ship’s stores, responsible behaviour while handling ship’s property and carrying out duties related to maintenance with due diligence. It is very important for juniors and crew members to understand that their jobs are secure to the point where the company is making profits and their contribution matters in ensuring that their company remains ‘afloat’ always.

Reducing ship’s running cost is a team effort in which every member contributes. Simple good habits such as switching off cabin’s lights can also go a long way in reducing costs. If one feels a sense of belongingness while working onboard ship, it is just natural to try and save whatever best one can – be it use of photocopy paper or ship’s stationary.

You may also like to read – Management And Procurement Of Spares On Ships – How To Identify, Order And Reduce Costs

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of The Marine Learners. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and The Marine Learners do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and The Marine Learners.

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.