Machinery onboard ships require regular care and maintenance so that their working life and efficiency can be increased, and the cost of operation, which includes unnecessary breakdowns and spares, can be reduced. For different types of machinery and systems, various measuring tools, instruments and gauges are used on a ship.

Measuring instruments and gauges are used to measure various parameters such as clearance, diameter, depth, ovality, trueness, etc. These are critical engineering parameters, which describe the condition of the working machinery.

Below, we have compiled a list of mechanical measuring instruments and mechanical gauges which are extensively used on the ship for the recording of different parameters.

There are many instruments, tools and gauges which are used on a daily basis onboard ship for measurement, fault finding, wear down etc.

Following are the essential tools, gauges and mechanical instruments and their uses:

They are used to measure lengths and other geometrical parameters. This tool is one of the most famous measuring instruments in mechanical engineering. They can be a single steel plate or a flexible tape type tool. They are usually available in the measuring scale of inch or cm.

They are used for quick measurement of parts and always kept with other measuring gauge or tools in the workshop for handy access. The ruler and scales are not used where precise measurement is required. It is made from stainless steel which is durable and will not rust or corrode.

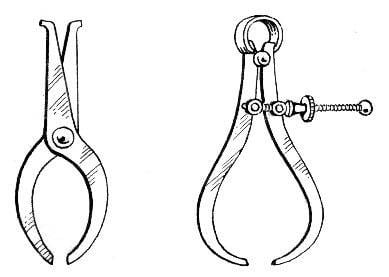

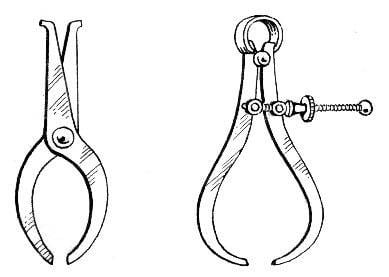

They are usually of two types- inside and outside calliper. They are used to measure internal and external size (e.g. diameter) of an object. It requires an external scale to compare the measured value. This tool is used on those surface where a straight ruler scale cannot be used. After measuring the body/ part, the opening of the calliper mouth is kept against the ruler to measure the length or diameter.

Some callipers are integrated with a measuring scale; hence there is no need of other measuring instruments to check the measured length. Other types are odd leg and divider calliper.

It is counted in the list of quality measuring instruments, which are used to measure small parameters with high accuracy. It has got two different jaws to measure outside and inside dimensions of an object. It can be a scale, dial or digital type Vernier calliper. Vernier calliper is one of the most used mechanical measuring tools onboard ship.

Least count of the vernier calliper is the difference between the values of main scale division and one vernier scale division.

Least Count= Value of one main scale division – Value of one vernier scale division.

= 1 mm – 9/10 mm = 1 mm – 0.9 mm = 0.1 mm or 0.01 cm

It is an excellent precision tool which is used to measure small parameters and is much more accurate than the vernier calliper. The micrometre size can vary from small to large. The large micrometre calliper is used to measure large outside diameter or distance. E.g. Large micrometre is used as a special mechanical measuring tool for main engine to record the outer diameter of the piston rod.

They are available in two types- Inside micrometre (to measure inside diameter) and Outside micrometre (for measuring outside diameter).

The Least count of the micrometre is 0.01 mm or 0.001cm.

Feelers gauges are a bunch of fine thickened steel strips of different thickness bundled together. The thickness of each strip is marked on the surface of the strip. The feeler gauge is used to measure the clearance or gap width between surface and bearings.

E.g. The feeler gauge is widely used to measure piston ring clearance, engine bearing cleaner, tappet clearance etc.

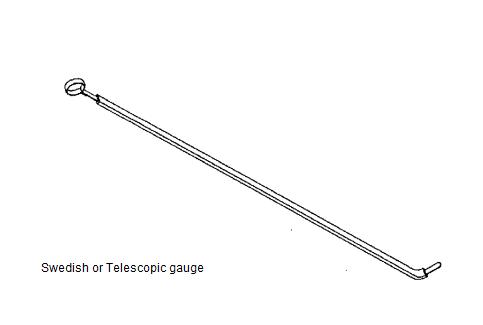

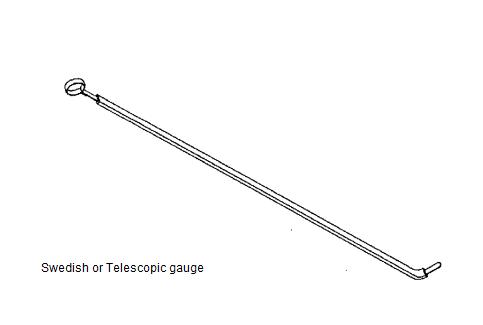

Similar to the functionality of feeler gauge, this type of gauge is also known as tongue gauge, and it consists of long feeler gauge inside a cover with tongue or curved edge.

The long feeler strips protrude out of the cover like a telescope so that it can be inserted into remote places where feeler gauge access is not possible. E.g. It is used to measure the bearing clearance of the top shell.

It is essential that after the use of the telescope gauge, the strip should be cleaned and retracted back to its housing, else it may damage the feeler strip.

Poker gauge is one unique tool among different types of measuring instruments is available in mechanical or digital form on ships. It is only used for one purpose; To measure propeller stern shaft clearance, also known as propeller wear down. It is a type of depth measuring instrument, whose reading indicates the wear down of the stern shaft.

A special access point or plate is provided which can be either open, bolted, secured or welded, depending upon the ship design. The Poker gauge is inserted to in this access point to measure the propeller drop. The poker gauge is a special instrument which is kept with the chief engineer, and the reading is usually taken every dry dock.

The design of the poker gauge may vary as each vessel has customised poker gauge made available during the handing over from the shipyard. While taking the reading the shaft to be turned, so that propeller boss matches with the marking of the shaft.

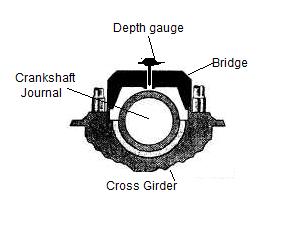

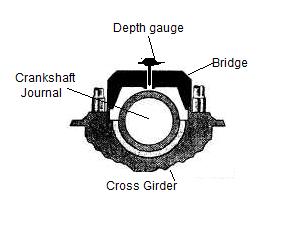

As the name suggests, Bridge gauge looks like bridge carrying the measuring instrument at the centre of the bridge. They are used to measure the amount of wear of Main engine bearing. Typically the upper bearing keep is removed, and clearance is measured for the journal. A feeler gauge or depth gauge can be used to complete the process.

A feeler gauge or depth gauge can be used to complete the process.

A liner measurement tool is a special tool for marine engines which comes in a set of the straight rod of different marked length, which can be assembled together to make the measuring tool of the required length. It is used to measure the wear down or increase the diameter of the engine liner.

It is considered as special tools when compared to other types of measuring tools and kept separately with other engine special tools under chief engineer or 2nd engineer supervision.

American wire gauge or AWG is a standard tool which is circular and has various slots of different diameter in its circumference. It is used to measure the cross section of an electric cable or wire. This tool is usually kept in the electrical workshop of the ship, and electrical officer uses it for measuring wire thickness.

A tool to accurately measure the diameter of any hole is known as bore gauge, It can be a scale, dial or digital type instrument. The most common type which is used on the ship is dial type bore gauge, which comes with a dial gauge which is attached to the shaft and replacement rods, also known as measuring sleds, of different size to measure different hole dimensions. It is usually calibrated in 0.001 inch (0.0025 cm) or 0.0001 inch (0.00025 cm).

A depth gauge is used to measure the depth of a slot, hole or any other surface of an object. It can be of scale, dial or digital type. The depth gauge can be a micrometre style type, a dial indicator type, or modified Vernier type tool, which means the measuring base is fitted on the reading scale of a micrometre, dial indicator or the Vernier scale.

As the name suggests, this is a tool comprising of two flat plates which are at a right angle to each other, and it is used to measure the exact right angle of an object or two objects joined together. This tool is usually kept in workshop away from any tools or chemical which may roughen the surface of the angle plate.

The flat plate or a surface plate is a precision flat surface used to measure the flatness of an object when it is kept over the flat plate acting as a reference. The flat plate is also kept in a workshop in a secure location, and a wooden piece is usually held on the top of the flat surface as the protective cover to safeguard the surface. Regular visual inspection and calibration need to be done to check for wear, scoring etc. on the surface.

The dial gauge is utilised in different tools as stated above and can be separately used to measure the trueness of the circular object, jumping off an object, etc. It consists of an indicator with the dial, which is connected to the plunger carrying the contact point. Once the contact point is kept in touch with an object (to be measured), any unevenness or jumping will cause the plunger to move.

The plunger is connected to the pointed in the dial. The dial is such attached that it does not retract but swings in an arc around its hinge point to show the reading in the indicator.

It is a conventional method to use soft lead wire or lead balls to measure the wear down or clearance between two mating surfaces. The lead wire or balls of fixed dimension (which is usually larger than the expected clearance) are kept between two surfaces, and both are tightened against each just as in normal condition. The change in the width of the lead wire or ball will show the clearance or wear down.

Also known as sounding tapes, these are special types of gauges only used to measure the level of the fluid (HFO, DO, Lubes, Water etc.) inside the ship’s tanks. The sounding tapes can be of a mechanical type where the tape is retracted in a coil and connected to a heavy bob at the end. The mechanical tapes are the most commonly used in all dry ships, however, in tankers ships, electronic sounding gauges, electrically powered servo type gauges, ultrasonic type etc.

A small glass instrument for measuring the density and saturation of the salt in the seawater. This is an essential tool for deck officers as the draft survey will be determined using the water density to calculate the cargo weight for loading. It is also used for ensuring compliance with the load line survey.

A form of dial gauge specifically made to measure the crankshaft deflection of the marine engine. The working is similar as explained in the dial gauge, the only difference is the construction which let this tool hang between two webs allowing it to measure the deflection when the crankshaft rotates.

A measuring instrument for a marine engine with pressure indicator dial used to measure the peak pressure generated inside the engine cylinder. The pressure indicator dial is connected to the blowdown valve located on the top of the cylinder. There is a check valve provided before the indicator, which when opens will the pressurised gases to continually flow inside the indicator till it reaches the maximum value in the dial.

Once the pressure is measured, an exhaust valve provided on the side of the valve is opened which release the pressurised gas from the instrument. It is an oil filled pressure gauge instrument which helps in resisting the vibration and also acts as good heat resistant.

It is a cylindrical device containing the indicator piston with spring and needle, used to draw the indicator diagram for a particular cylinder when it is fixed on the indicator cock of the unit.

The internal pressure changes in the cylinder are transferred to the indicator piston which is balanced with the spring. The displacement in the piston is magnified and transformed into an indicator diagram by using a precision link mechanism connected to a metal stylus.

An instrument which is used to measure areas of irregularly shaped areas of an arbitrary two-dimensional shape on plans or drawings.

These are some of the primary tools and gauges types that are used on board ship. If you feel we have missed any vital tool, then let us know, and we will add it to the list.

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of The Marine Learners. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and The Marine Learners do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and The Marine Learners.

SaveSaveSaveSave

SaveSaveSaveSaveSaveSaveSaveSave

SaveSaveSaveSaveSaveSave

SaveSaveSaveSave

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.