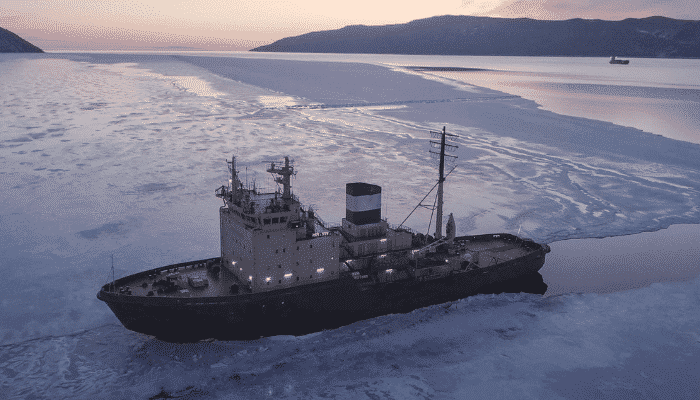

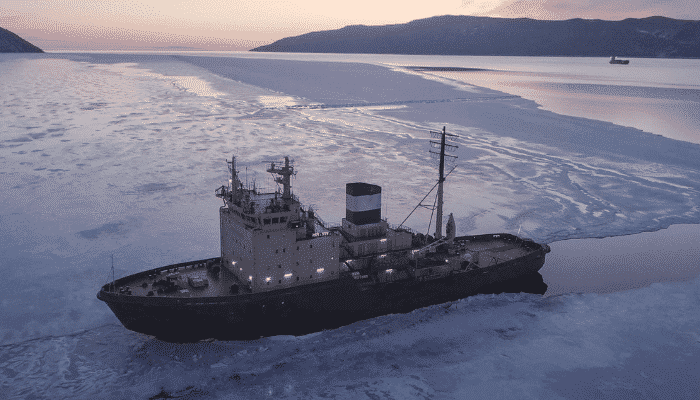

Ships plying in international waters have to travel to remotest areas of the world, irrespective of weather conditions and that too in limited amount of time. This makes the ship travel through sudden changes of climatic conditions, for e.g. a ship after passing through hot African Continent can enter freezing waters of Europe within few days.

Because of this, ship and its equipment also experience drastic temperature changes. Vessel equipments and machineries are installed with special systems so as to allow them to work in the harshest conditions. However, the operator, i.e. seafarers on board ship must take all the precautions especially when the ship is about to enter sub zero temperature regions.

Various precautions to be taken at deck and engine when the ship is about to enter sub zero temperature areas are:

Deck Precautions

Engine room precautions

Personal Precaution

References: dnv

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.