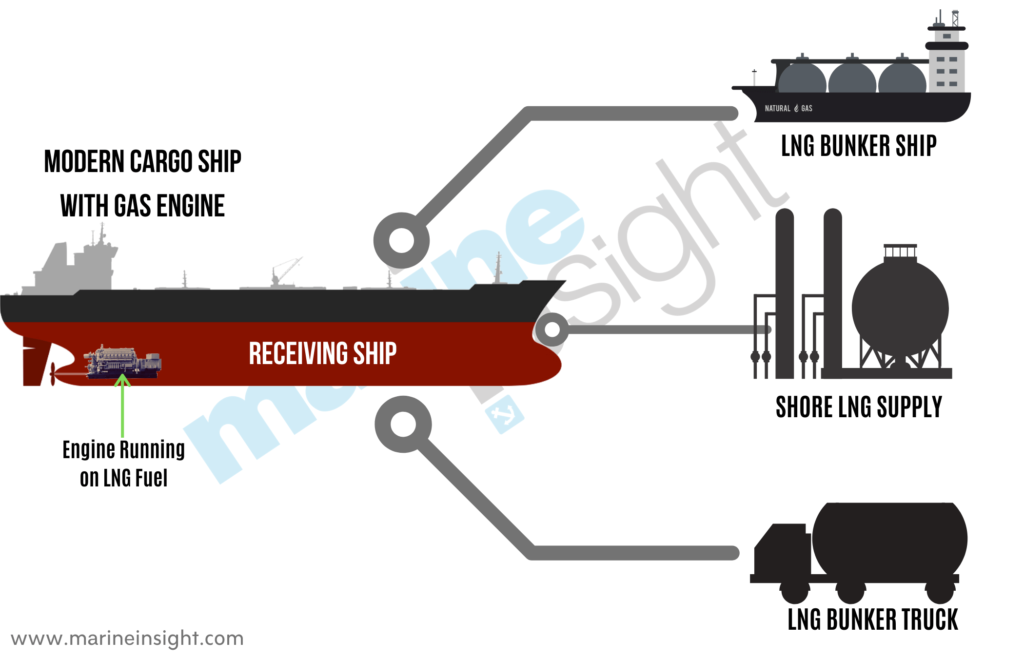

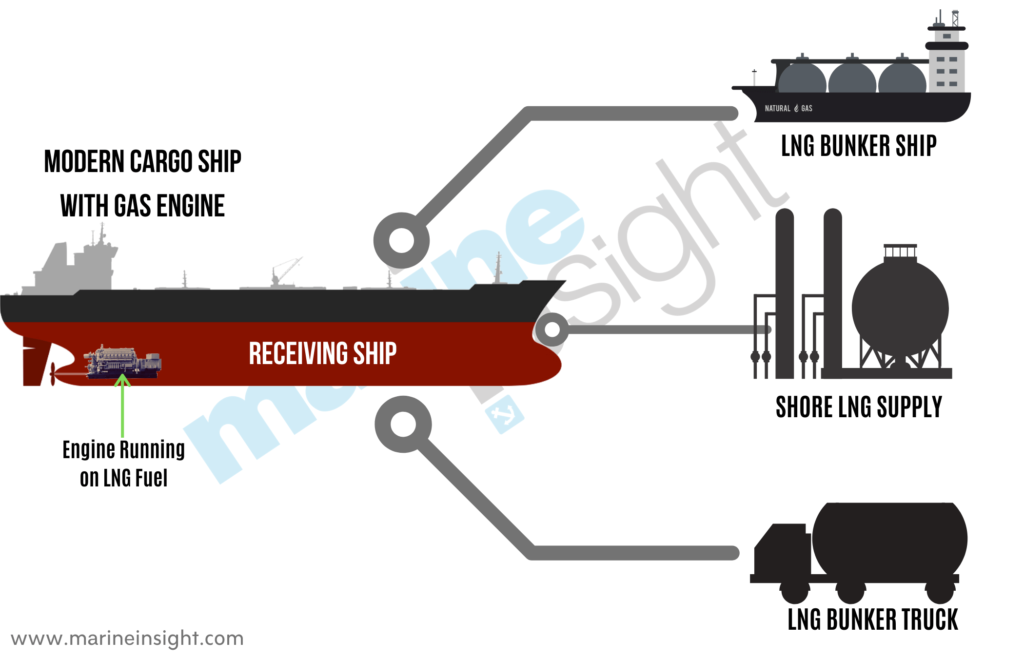

With the stringent sulphur regulation coming into action in 2020, ships with LNG fuels can be seen playing in the international waters.

Different types of ships, including cruise and containers ships, are fitted with engines which can burn LNG fuel to reduce harmful emissions from the exhaust of the ship.

LNG fuel is different in properties when compared to conventional heavy fuel oil or LSFO used on ships. Due to its cryogenic temperatures where it can be stored and transferred, the procedure for transferring the fuel into the ships requires a more safe approach when compared to other fuel oils.

For LNG fuel bunkering, it is important to follow regulations laid down by local port authorities and permissions need to be taken from them. IMO IGC code needs to be followed by the bunker ship which will carry the fuel and would be transferring it to the cargo or passenger ship. For the ship which will be receiving the LNG bunker fuel, it will follow the IMO IGF Interim guidelines.

The Master needs to check the weather and tide forecast for the area where LNG bunkering operation is to be carried out. As far as possible, conduct the bunkering operation during the daylight. The bunkering station and nearby areas of the ships are treated as EX-classified areas during the bunkering period for both the ships when it is ship to ship operation.

Leaks and accidental spills: Like any other fuel used on board ship, the chances of leakage and spillage of LNG will be there as it will be transferred from ship to ship or shore to ship using portable pipes and connections which may get loose, break or rupture.

Cryogenic hazards: LNG as a fuel will be carried and transferred at a very low temperature of – 162 deg C. and in case of any leakage and human contact, it will lead to frostbite and cryogenic burns to human skin.

LNG fire and explosion hazards: LNG is carried liquid state so that it can be carried in the maximum quantity, and it can only be ignited in a gaseous state when the concentration of natural gas vapour is within its flammable range. LNG fuel is associated with following fire hazards-

Rapid Phase Transition (RPT) – When the LNG comes in contact with another source leading to heat transfer, which may lead to a phase transition from liquid to vapour at a faster rate.

Bunker Line Contamination: The bunker lines are opened to the atmosphere and if it contains moisture, salt or CO2, during the bunkering operation they will be rapidly cooled down and form ice which will block the pipe passage.

Trapped LNG: Once the bunkering is finished, it is possible that some amount of LNG fuel is left in the pipe which will convert and expand into vapour which will create high pressure inside the pipe leading to rupture

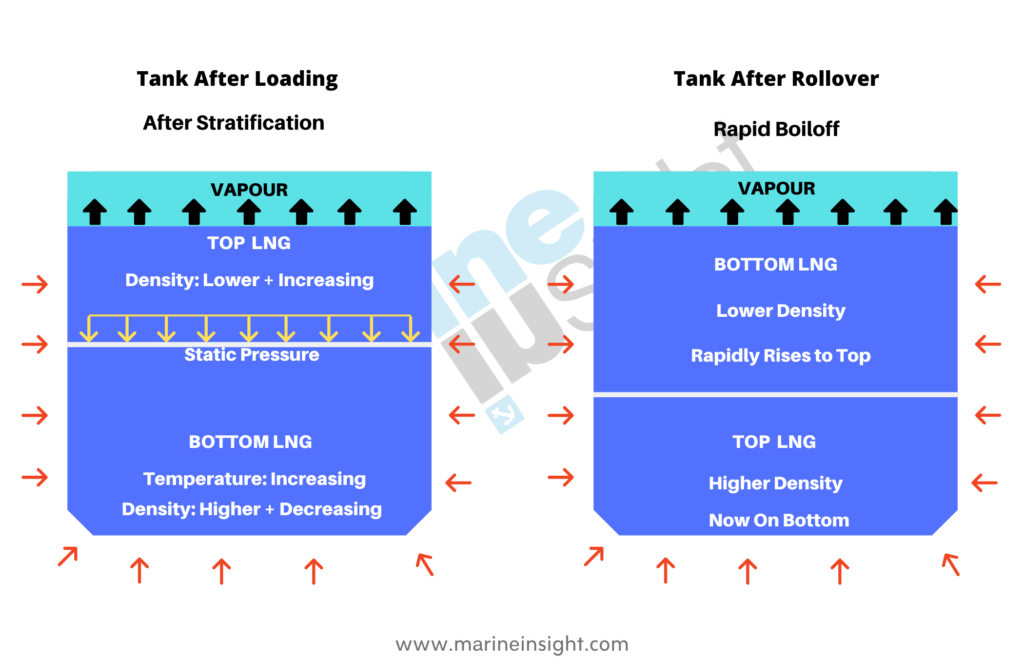

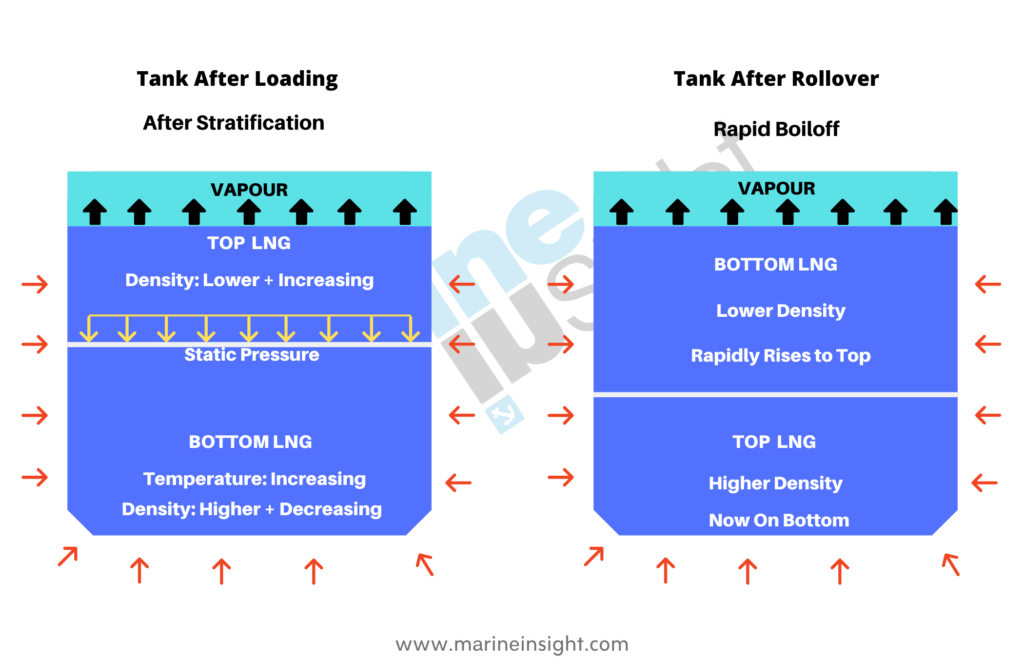

Rollover: The rollover occurs due to rapid release of LNG vapours from a storage tank caused by stratification which arises when two separate layers of different densities of LNG is present in the tank as there can be temperature difference in the tank surface from top to bottom.

Lack of Oxygen deficiency: If LNG is spilt in confined space, it may lead to oxygen depletion as it will vapourize and displace the air present in the atmosphere in that chamber.

Hence, the ship’s crew handling the LNG bunkering operation must be aware of different hazards related to it and must have detailed instructions in terms of training and checklists for the procedure which must include the responsibility of each crew in case any of it takes place.

These instructions must be kept or displayed such a way that they are readily available at all times and crew must make themselves familiar with its content.

The emergency shutdown device or switch must be present in both the ships (bunker ship and receiving ship) and the crew must operate/ use it when:

When there is any of the hazard taking place explained above

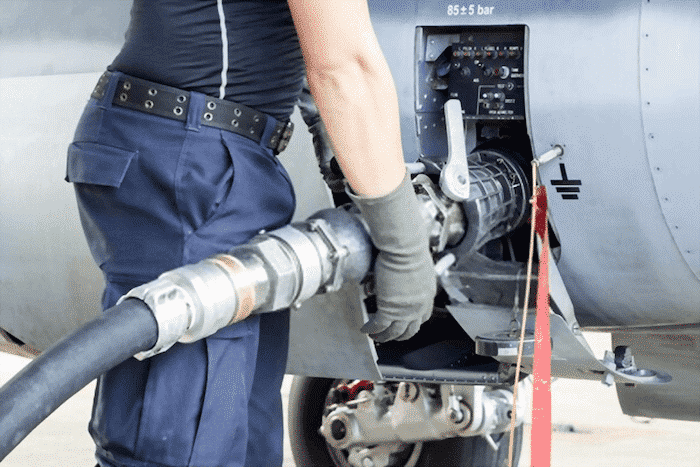

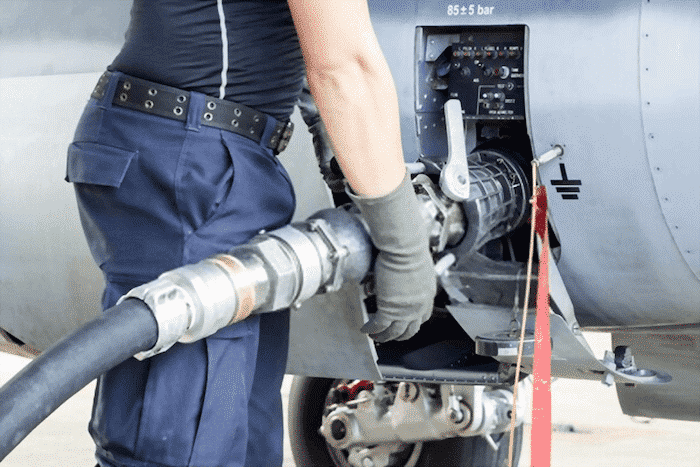

The LNG bunkering between ship to ship or shore to ship is done by using a QC/DC coupling.

QCDC stands for “quick connect disconnect”. The coupling used in the LNG bunker hose us usually a drybreak coupling which comprises a female (hose end) fitting and a male (tanker fitting) that are connected/disconnected on a regular basis to form a liquid and pressure-tight coupling.

Daybreak couplings generally have a valve arrangement that shuts down the liquid flow prior to the disconnection of the male and female couplings. Hence, the coupling can not be disconnected while underflow condition.

Another advantage of QCDC is that its fast connect/disconnect time allowing the crew to have a faster operation. Low-pressure drop in the pipeline through the coupling allows faster filling.

A nominal size couplings of up to 6 works for flows up to 650 m3/h, with a maximum flow rate of 10 m/s. The LNG bunker hoses are to be clearly colour-marked according to a defined system so that there will be no risk of using an incorrect hose type.

Related Read: LNG Tankers – Different Types And Dangers Involved

The properties of LNG fuel is different than the conventional oil hence the crew involved in the bunkering of LNG should use these additional PPEs apart from the basic ones:

The engine room and deck crew work together in preparing for the LNG bunkering operation. Once the LNG bunker ship arrives, both the ship’s crew moor them with each other.

The pre bunkering checklists of both the ships should be signed off by both parties prior to the operation. The master of the cargo/ passenger ship and representative of LNG bunker ship or truck must agree in writing regarding the transfer procedures, i.e. the maximum loading or unloading rates and modes of communication etc.

Other checks shall include the following:

It is not compulsory for the bunkering vessel to provide a vapour return line. The requirement of vapour return line will depend on the receiver vessel and it may not need it if –

Once the LNG bunkering operation starts, dedicated ship team members must keep checking the bunker station and filling tanks for the following:

Related Read: Understanding Sounding, Ullage, and Frequency of Sounding

If the watchkeeping officer and crew detects a single issue, the bunkering operation must be stopped immediately either by communication or the use of Emergency Stop Device depending upon the nature of the problem.

Once the supplier communicates that the quantity of LNG fuel decided has been transferred, the pumping will be stopped or during the top up, the pumping rate will be reduced and then stopped.

LNG in lines is allowed to vaporize and displace the remaining liquid back to the tanks.

The manifold valve for bunkering and vapour line on the receiving ship is shut

The pipes and hoses used for bunkering will be inerted

Ship officer will confirm if bunker hoses, manifold, and piping are properly drained and free of residual LNG

The bunker pipe and vapour line hose are disconnected and it will be taken back by the supplier ship

The bunker hose manifold will be blanked and all the FFA and pollution prevention equipment are kept back

The quantity will be finally checked as per the tank levels and Bunker Delivery Note will be received by the ship’s Chief engineer

The mooring lines will be open and the castaway. The same to be recorded in ship’s logbook and informed to the port authorities

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of The Marine Learners. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and The Marine Learners do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and The Marine Learners.

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.