CONEX containers are one of the most iconic developments in the history of transportation and logistics, as they revolutionized the shipping industry.

These containers gave rise to the industrial intermodal standard containers known today as TEU and FEU.

Intermodal containers can be transported using road, rail and maritime methods. In some instances, they can also be transported by air when the aeroplane stowage systems are modified to accommodate their specific dimensions.

The term CONEX is an abbreviation of Container Express, indicating that transport times were cut short by having a single container compatible with multiple means of transport.

During the wars in Korea and Vietnam, US troops needed quick methods of ferrying supplies to the soldiers at the front lines.

The issue was that goods loaded on container vessels had to be reloaded onto trailers for road transportation. This presented a logistical challenge, as valuable time was spent in the transfer process.

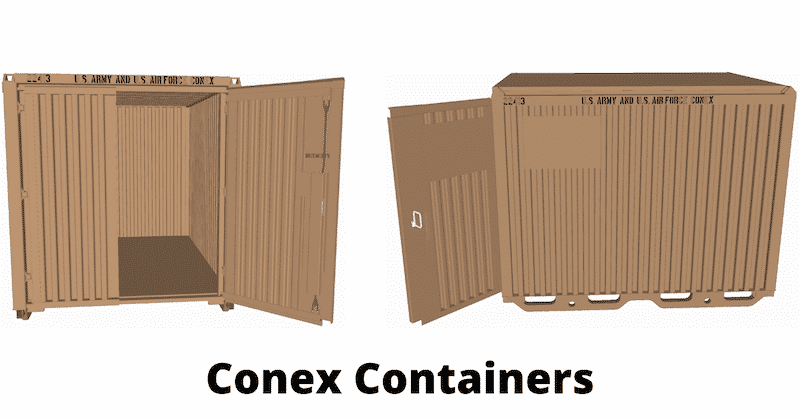

A unique design known as the CONEX box was developed to overcome this. This box was compatible with the trailers on which they could be carried.

In addition, they had locking mechanisms that could connect adjacent boxes to prevent toppling over during transport. The first model of these intermodal containers was the “Transporter” used in deployment during World War II to ferry supplies to the war front.

The basic design had a 4,000 kg weight limit and was made of corrugated steel to serve as protection.

Related reading: How are shipping containers made?

Further technological advances allowed skids and lifting mechanisms to be attached to the early designs. These ensured that the containers snugly fit during transport and that they could be easily picked up by cranes and loaded onto trailers.

During the Korean war, containers were modified to store larger quantities of goods without compromising structural integrity. The Vietnam war witnessed larger CONEX boxes being developed that could double up as living quarters during harsh conditions.

During transport, they could be stacked three containers high and were lashed together to prevent accidents.

The modern intermodal containers were developed from the rudimentary CONEX boxes by American trucking magnate and businessman Malcolm McLean, who revolutionized the transport industry.

CONEX containers are still in use by the US military but have been renamed BICON, TRICON and QUADCON containers. These containers are unique to military usage and vary in dimensions from the standard intermodal containers.

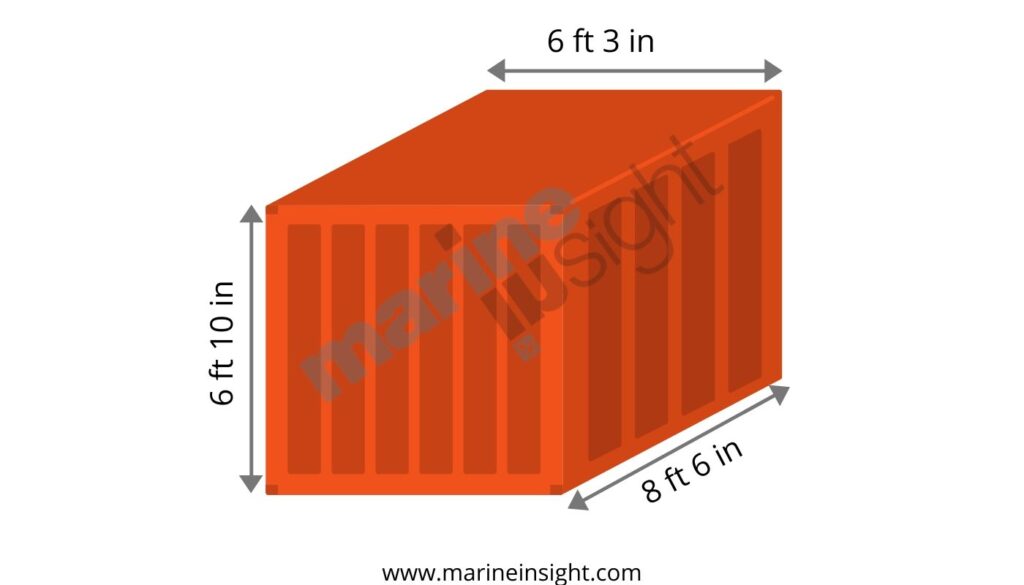

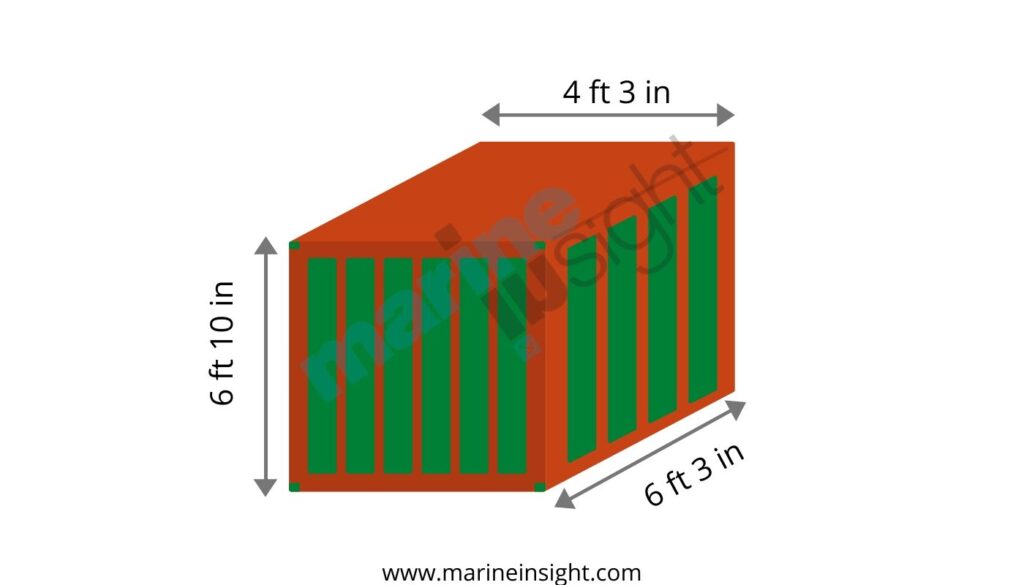

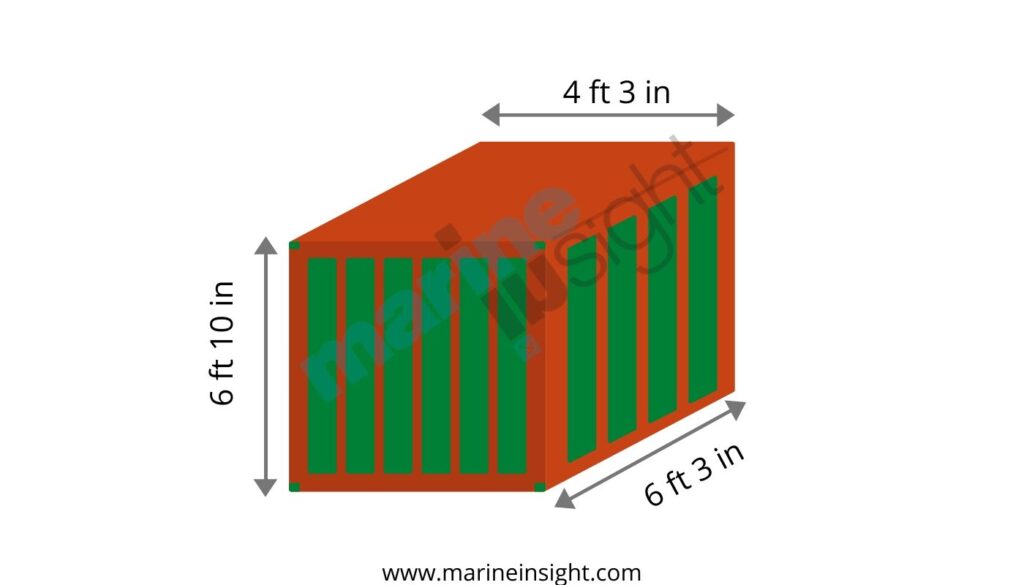

The generic sizes of the CONEX containers have varied over time to suit the various types of cargo it has been used to accommodate. During the wars, the early model known as the “Transporter” used for moving supplies was 8 ft 6 in long, 6 ft 3 in wide, and 6 ft 10 in tall.

Half units of smaller dimensions, 6 ft 3 in long, 4 ft 3 in wide and 6 ft 10 in tall, were used in shipping where space constraints were present.

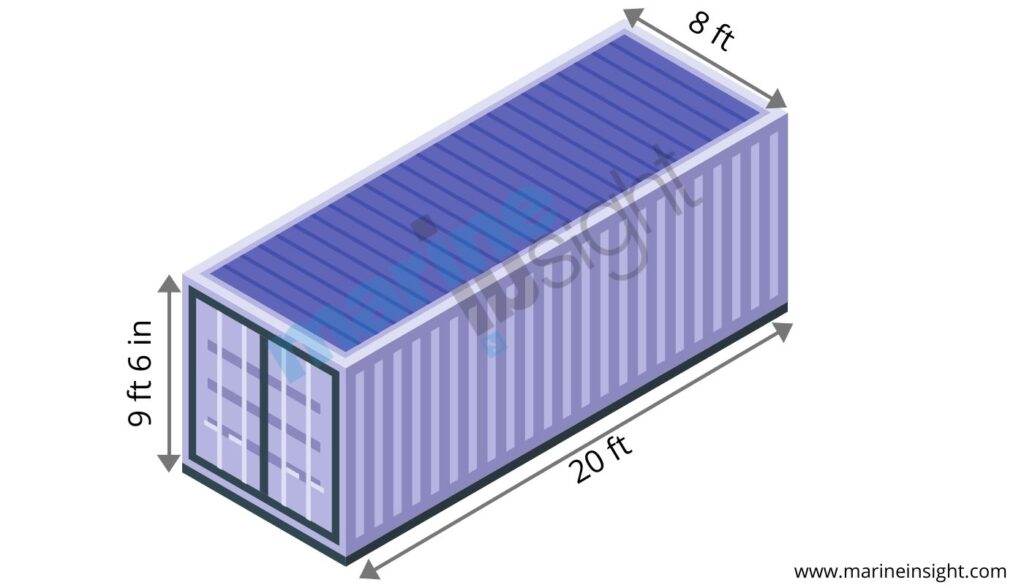

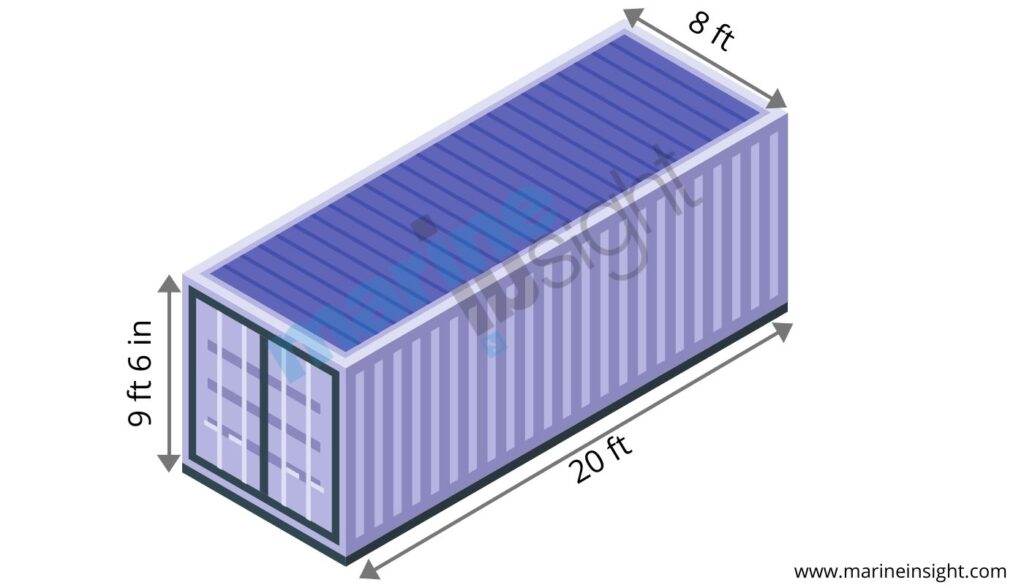

The modern CONEX containers have standard sizes in the Twenty-foot Equivalent Unit (TEU) and Forty-foot Equivalent Unit (FEU).

Related Reading: Different types of shipping containers

As the names suggest, these containers are respectively 20 and 40 feet long and are intermodal. To ensure compatibility and even spacing on ships and trains, the width and height are fixed at 8 ft and 8 ft 6 in, respectively.

For larger space requirements, high cube or hi-cube dimensions are used. These are the same length and width but are taller than conventional containers at 9 ft 6 in.

Along with these standards, more unusual sizes are also in circulation, such as the 10 ft, 25 ft, 45 ft, 48 ft and 53 ft long containers.

Certain types of cargo require compact or larger storage spaces, so they utilize these types of shipping. The volume loading capacity of these containers can vary as 33,000 litres for the TEU containers, 67,500 litres for the FEU containers or 75,300 for the FEU hi-cube variant.

The maximum gross weight permissible on board these containers is 30,000 kg for the TEU and FEU sizes, while it goes slightly up to 31,000 kilograms for the FEU hi-cube size.

On average, the weight of the empty containers ranges between 2,200 for the TEU and 3,800 kg for the FEU.

The distinguishing features of the CONEX containers that set them apart from the older variants of the container industry were their superior safety, strength and compatibility.

These containers were built out of corrugated steel sheets and could withstand sufficient forces and strains before crumpling. In addition, a specialized locking mechanism was in place that prevented the theft of the goods inside.

Certain containers required windows and additional entryways. In such cases, a common double locking mechanism in modern-day containers was put in place to secure the doors.

Also, steel bars and bullet-proof glass were used on windows to prevent theft. The strength of these containers came from the corrugated shape, which increased the maximum bending stress along the axis perpendicular to the shape distortions.

A vital feature of the CONEX containers was the interlocking mechanisms present on the exterior. For instance, the early designs had skids on the bottom that could fit perfectly over containers below it.

With advances in manufacturing, the containers could also be locked to the adjacent storage units.

For this purpose, a specialized mechanism was used to connect the bottom of two adjacent units, which could be released as and when needed.

In addition to all these features, safety and administrative laws could now be easily applied, as a uniform standard was used for all the containers shipped across the world.

CONEX containers can be used for various purposes, differing based on the type of goods they house within themselves.

General purpose dry containers can ship cartons, pallets, drums and boxes. They are apt for transferring similar types of dry goods.

They can include unique mechanisms built for particular goods that can be difficult to load into the container. For instance, garments that cannot be folded and transported are stored on hangers and shipped using garment containers.

Along with garments, storing heavy pallets is difficult since cranes can often not be used to directly place the goods within the allocated location in the container.

To solve this issue, rollers on the container floor are used to shift the goods quickly. Large cartons and pallets can be loaded in this manner, using only limited personnel to load goods into the container.

For transporting liquids, powders and gases, tank containers are commonly used. These consist of multiple pressurized tanks stored in the container such that large quantities of fluids or powders can be shipped.

For cargo such as toxic gases, or poisonous liquids, special signs are installed at the doors and on individual tanks to prevent accidents and mishaps. Along with pressure regulation, certain gases must be maintained at specific temperature and humidity ranges.

Here, temperature-controlled containers can be put to use. These include insulated containers maintained at a constant temperature through refrigeration or heating. These are also ideal for perishable goods such as fresh foods, especially meat.

Thermally insulated containers can also be used with the same features for dry goods that have to be kept under specific storage conditions. In addition, ventilated containers are also available. These have unique mechanisms for active ventilation (using a pump system) or passive ventilation (using air drafts through ventilation holes in the container) that ensure goods reach their final destination in the right condition.

Another common method of transporting goods, especially loosely stored items or powders, is using bulk containers. Similar to bulk carrier vessels, these containers are rigid on all four sides and at the bottom. However, the top is sometimes made separately or with specialized gaps for loading loose items. This includes large-scale shipping of powders, grains, and loose materials such as ores and rocks.

For a fine matter that can easily be lost if not stored properly, movable bins are used to collect the material. Once filled, the individual bins are loaded onto the containers and stacked along the entire length. These bins are handy, as they allow companies to roll on directly and roll-off goods during loading and unloading operations.

It removes the need for specialized pumps or motorized mechanisms to unload the goods at the destination. For such containers, the top is often removable or made of flexible material with a slit that allows factories to load material without the danger of spilling directly.

Another type of container similar to the one previously discussed is the open-top container, which can be used to store large objects that would have otherwise required the container to be dismantled. This is ideal for large machinery that must be loaded through the top.

The difference between the open-top and bulk containers is that while bulk containers can have removable lids, the open-top ones often do not have a roof for the containers. The benefit is that multiple containers can be stacked and used for transport with minimum modifications for massive objects.

To stack these containers, the bottoms are removed for certain ones, and the object is placed in the stack using specialized cranes at dockyards. Open-side containers can be used to slide objects into the container without having any issues with loading. In addition, having open sides can aid in ventilating the goods stored within. This is ideal for perishable foodstuff such as potatoes and apples that will be able to withstand the journey without extra protection.

It was developed during the Korean war and used to transport and store war supplies during the Vietnamese and Korean wars. It was reinvented by Malcolm Mclean, who gave it the form of a standard intermodal shipping container, used widely by shipping companies today.

They were extensively used during war times. This logistics method was called Container Express, hence the name Conex. They are also called intermodal containers due to their ease of transport from one destination to another.

A 40ft high cube container will cost an average of 5,320 US Dollars. Although, a 20ft reefer container would cost 12,800 US dollars.

A seaworthy Conex container is watertight. It has rubber seals around its doors to keep the seawater, including rain, out of the interior. A waterproof container can lock and hold a liquid inside without spilling it.

Whether we call them shipping containers or storage containers, Conex or Conex boxes, or ISO boxes, they all mean the same thing. They are large metal boxes for transporting goods at sea.

You might also like to read

Disclaimer: The author’s views expressed in this article do not necessarily reflect the views of The Marine Learners. Data and charts, if used in the article, have been sourced from available information and have not been authenticated by any statutory authority. The author and The Marine Learners do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendations on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and The Marine Learners.

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.