Marine air compressor is an extremely important auxiliary machinery on ships and other ocean going vessels. It is used for producing compressed air, which has a number of applications on board, both in the engine and deck departments.

It’s a duty of a marine engineer to ensure that the ship’s air compressor is running smoothly and efficiently. Moreover, as several other machinery systems in the engine room are dependent on the air compressor for their operation, it is important that the compressor is kept in up-to-date condition all the time.

This ultimate guide to marine air compressors provides all the details which you would require to understand, operate, and maintain a compressor on a ship.

As mentioned earlier, the air compressed produced by air compressors is used for a variety of purposes on ships, ranging from starting of main engine to cleaning and maintenance purposes. Read this to find out how compressed air is used in daily routine and maintenance jobs of ships.

Learn about the basics of air compressor used on ships, along with a general overview of different types of air compressors used on board and their applications. This is a must read for all those marine engineers who are just starting their careers at the sea. It is also an excellent resource to brush up your air compressor basics.

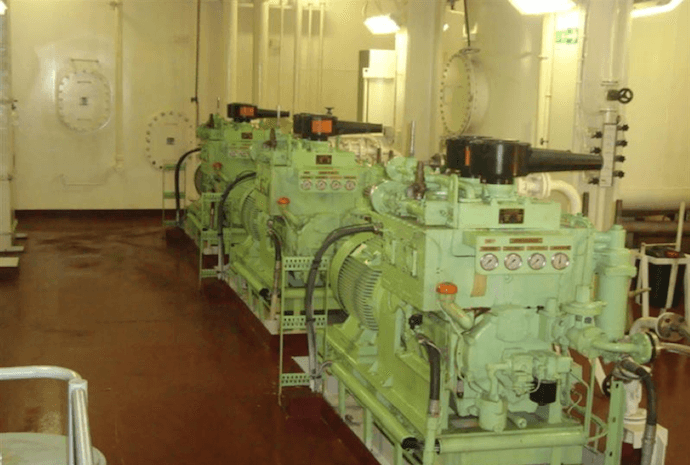

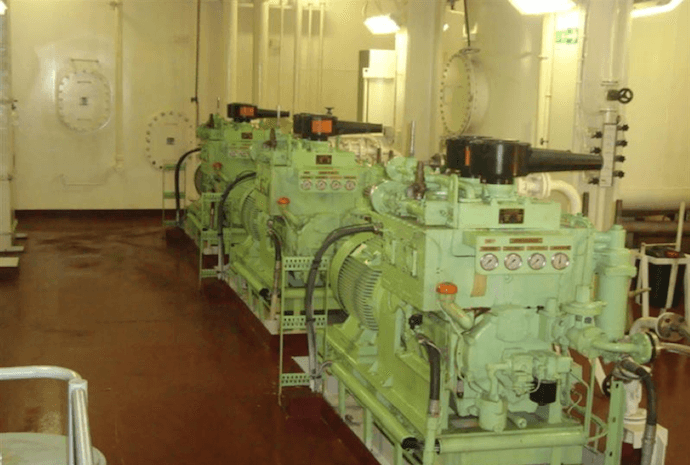

Different parts of a marine air compressor

Know about different parts of marine air compressor and how they function together to deliver the compressed air. If you want to get a detailed explanation about each part of the air compressor, then this is a must read article for you.

Starting and stopping a marine compressor

Once you have familiarized with the basics and different components of marine compressor, it is time to get your hands on the machine by learning to start and stop the same without any errors.

This is the ultimate checklist for a marine engineer, who wants to start, operate, and stop the marine compressor in the right manner to avoid any damage to the machinery.

Many ships also have a breathing air compressor on board. Find out the procedure to start this compressor here – Procedure for starting breathing air compressor

Safety features and maintenance procedure of marine air compressor

If you are a marine engineer, you would be more interested in the maintenance and repair of marine compressors.

If you are doubtful about the maintenance procedure you should follow, then read this to find out about different safety features that are found on compressors and how maintenance should be done.

As you carry out routine maintenance of the air compressors, you would also assess the performance and efficiency of the machine. Find out about the different factors which decide the efficiency of the air compressor and what steps should be taken to ensure efficient running.

Understanding of Clearance Volume (bumping clearance) of air compressors

While carrying out the maintenance of the air compressor, clearance volume is one aspect which is of utmost importance. It is imperative that every marine engineer understands the importance of measuring bumping clearance along with the procedure to do so.

Find out the significance of bumping clearance and how it is checked in here.

Air compressor condition report

A marine engineer has to make report after he has carried out maintenance and repair work on the air compressor. Here’s a free report sample for you in case you are not sure as to how to make it.

The compressed air produced on ships is stored in an air bottle, from where it is supplied to different systems. Find out more about the construction, working, and importance of air bottle on ships in there.

Do you think we have missed to mention any important aspect of marine air compressor? Let us know and we will include it in here.

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.