Discarding sewage produced onboard on a ship is one of the few tasks on a ship which should be taken utmost care of if one wants to save him and his shipping company from heavy fine. The sewage generated on the ship cannot be stored on the ship for a very long time and it, for this reason, it has to be discharged into the sea.

Though sewage can be discharged into the sea, we cannot discharge it directly overboard as there are some regulations regarding discharging of sewage that needs to be followed. Sewage on the sea is generally the waste produced from toilets, urinals, and WC scuppers. The rules say that the sewage can be discharged into the seawater only after it is treated and the distance of the ship is 4 nautical miles from the nearest land.

But if the sewage is not treated this can be discharged 12 nautical miles away from the nearest land. Also, the discharged sewage should not produce any visible floating solids nor should it cause any discoloration of surrounding water. The details of the sewage discharge regulations can be found in MARPOL Annex IV.

Related Read: MARPOL ANNEX 4 Explained: How to Prevent Pollution from Sewage at Sea

Generally, ships prefer treating sewage before discharging to save themselves from any type of embarrassment. There are different methods of treating sewage available in the market, but the most common of them is the biological type for it occupies less space for holding tank, unlike those of the other methods. Moreover, the discharge generated from this plant is eco-friendly. It is to note that each sewage treatment system installed onboard has to be certified by classification society and should perform as per their requirement and regulations.

The most preferred type of sewage treatment plant is that involving aerobic bacteria. The Anaerobic bacteria are equally capable of decomposing and breaking down the sludge but during the process, they generate and release harmful gases such as H2S and methane which are toxic and dangerous for aquatic organisms.

Related Read: 4 Important Terms Related to Sewage Treatment Plant on Ships

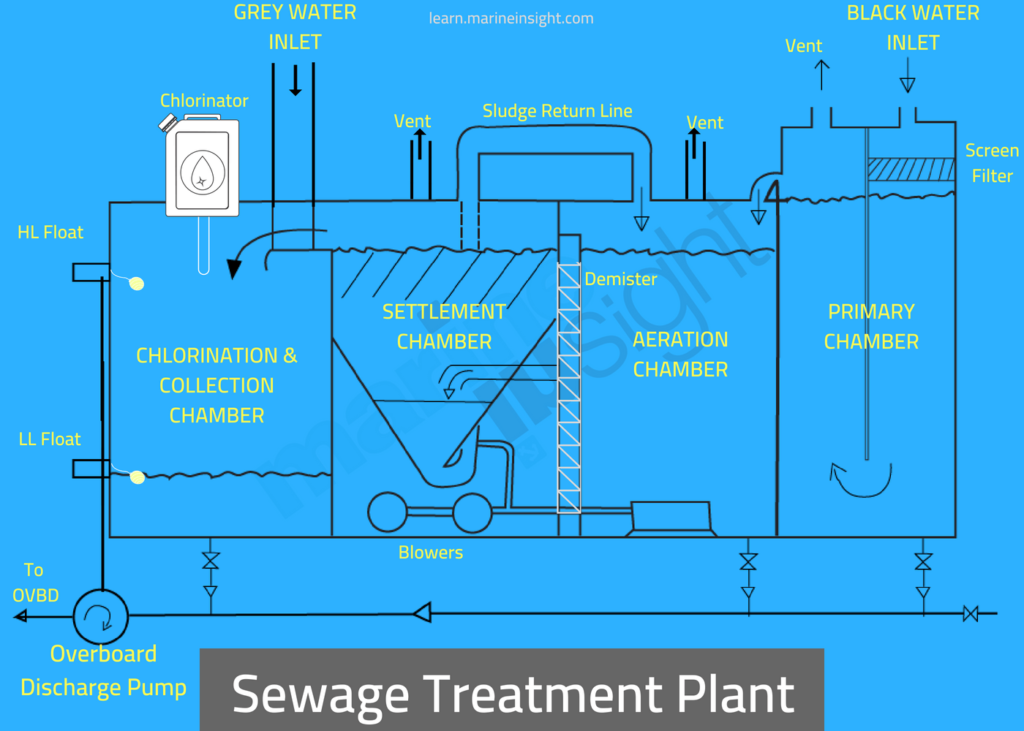

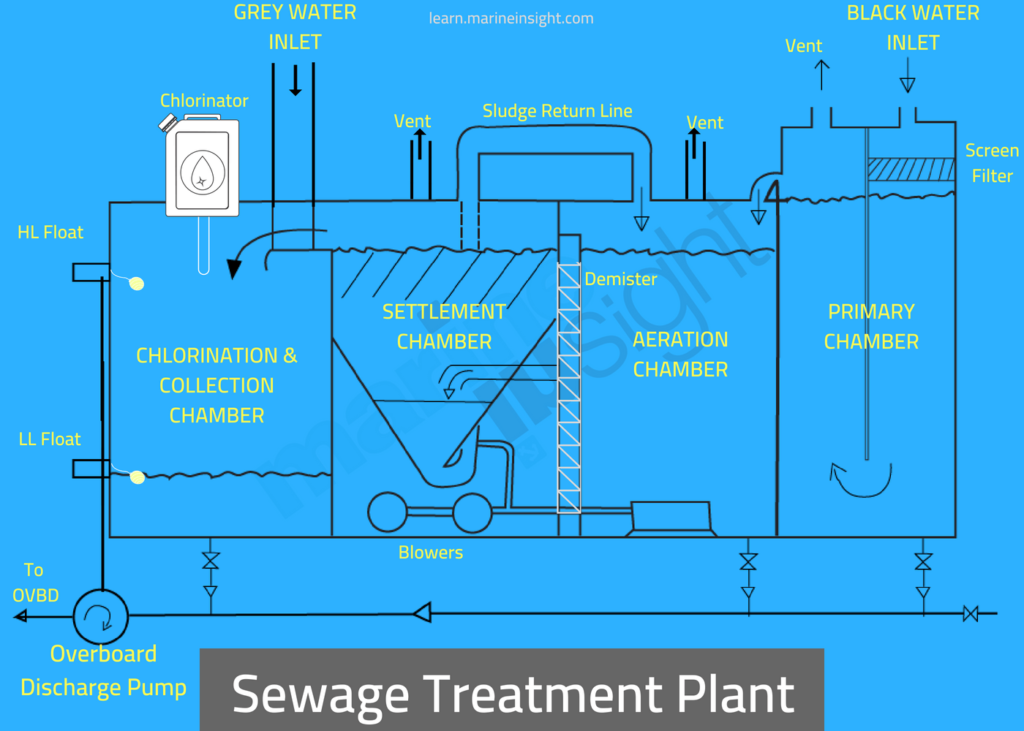

Screen Filter:

The screen filter mesh is fitted on the first tank near the entrance of the sewage to the STP. It helps in removing the non-sewage adulteration component such as; toilet paper, plastic paper, other solids etc, which can clog the complete system if went inside.

Biofilter:

The biofilter is also the part of the aeration chamber which treats the sewage passing from the screen filter. The biofilter reactor, with the help of fine air bubbles supplied from the blower, will disperse the contaminated substance diffusing and breaking down the organic matter by the aerobic microorganism. The fine bubble by passing through the diffuser will increase the oxygen transmission rate.

Settling/ Sedimentation Chamber:

The treated sewage water from the biofilter reactor will come to the next chamber which is used for settling purpose. The mixture will be further separated to high-grade water and sediment after being settled in Sedimentation tank. The clarification compartment is usually of the hopper type with sloping sides which prevent the sticking and accumulating of sludge and send it to the suction side of the air lift tube.

The untreated sludge settled in the bottom of the sedimentation tank returns into the Biofilter reactor to break up by microorganism again.

Activated Carbon:

The activated carbon is fitted post the settling chamber to remove Chemical Oxygen Demand (COD) by filtering and absorption. It also helps in treating the Biological Oxygen Demand (BOD) and Suspended Solids.

Chlorinator:

The chlorinator is fitted in the last chamber to treat the final stage water for discharging overboard. The chlorinator can be of tablet dosing type or chemical injection type. Inside the tablet-based chlorinator, clean water comes directly in contacts with the chlorine tablets, making a chlorine solution. The chlorinator comprises cylinders for filling the chlorinator with tablets.

In chemical pump type, a measured set quantity of NaOCl is injected to sterilization/chlorination tank using the diaphragm type reciprocating pump.

Related Read: Different Systems In Ship’s Accommodation Area Explained

Air Blower:

There are usually 2 air blowers installed, in which one acts as stand-by, to supply air (via air bubbles) helping in forming the microorganism in biofilter reactor. It also helps in transferring the sludge from sedimentation tank, supply air to the activated carbon tank and to back flush the sludge.

Discharge Pump:

The discharge pump is provided in a duplex and they are mounted on the last compartment of the STP. They are centrifugal pumps of the non-clog type which are coupled to their respective motors. The pump is run on auto mode controlled by the level switches installed in the sterilization tank. The pump is usually run on manual mode when taking out the sludge from the compartments after the cleaning of the tank insides.

Piping:

Related Read: Pipes and Bends – An Essential Guide for Second Engineers

Floats and Level Switches:

The basic principle of the working of a biological treatment plant is decomposition of the raw sewage. This process is done by aerating the sewage chamber with fresh air. The aerobic bacteria survive on this fresh air and decompose the raw sewage which can be disposed of in the sea. Air is a very important criterion in the functioning of the biological sewage plant because if air is not present, it will lead to the growth of anaerobic bacteria, which produces toxic gasses that are hazardous to health. Also, after decomposition of the sewage with anaerobic bacteria, a dark black liquid causes discolouration of water which is not accepted for discharging. Thus in a biological sewage treatment plant, the main aim is to maintain the flow of fresh air.

Division of Processes

The biological sewage plant is divided into three chambers:-

Aeration chamber

This chamber is fed with raw sewage which has been grounded to form small particles. The advantage of breaking sewage in small particles is that it increases the area and a high number of bacteria can attack simultaneously to decompose the sewage. The sewage is decomposed into carbon dioxide, water, and inorganic sewage. The air is forced through the diffuser into the air chamber. The pressure of air flow also plays an important role in decomposition of the sewage. If the pressure is kept high then the mixture of air and sewage will not take place properly and it will escape without doing any work required for decomposition. It is for this reason; controlled pressure is important inside the sewage treatment plant as this will help in proper mixing and decomposition by the agitation caused by air bubbles. Generally, the pressure is kept around 0.3-0.4 bars.

Related Read: How Can Ship’s Crew Contribute towards Reducing Waste Production Onboard Ship?

Settling tank

The mixture of liquid and sludge is passed to settling tank from the aeration chamber. In the settling tank, the sludge settles at the bottom and clear liquid on the top. The sludge present at the bottom is not allowed to be kept inside the settling tank as this will lead to the growth of anaerobic bacteria and foul gasses will be produced. The sludge formed is recycled with the incoming sludge where it will mix with the later and assist in the breakdown of sewage.

Chlorination and Collection

In this chamber, the clear liquid produced from the settling tank is overflown and the liquid is disinfected with the help of chlorine. This is done because of the presence of the e-Coli bacteria present in the liquid. To reduce these bacteria to acceptable level chlorination is done. Moreover, to reduce the e-Coli, the treated liquid is kept for a period of at least 60 minutes. In some plants, disinfection is also done with the help of ultraviolet radiation. The collected liquid is discharged to overboard or settling tank depending on the geological position of the ship. If the ship is in restricted or near coastline then the sewage will be discharged into the holding tank; otherwise, the sewage is discharged directly into the sea when a high level is reached and is disposed of automatically until low-level switch activates.

Precautions for efficient operation of STP:

Related Read: Maintenance and Checks for Sewage Treatment Plant on Ship

Special Area Regulation:

Currently, the Baltic Sea area is the only Special Area under Annex IV. The discharge of sewage from passenger ships within a Special Area is generally be prohibited under the new regulations, except when the ship has in operation an approved sewage treatment plant and additionally meet the nitrogen and phosphorus removal standard.

Related Read: 8 Ways in which Cruise Ships Can Cause Marine Pollution

In accordance with resolution MEPC.275(69), the discharge requirements for Special Areas in regulation 11.3 of MARPOL Annex IV for the Baltic Sea Special Area shall take effect:

1 on 1 June 2019, for new passenger ships;

2 on 1 June 2021, for existing passenger ships other than those specified in 3; and

3 on 1 June 2023, for existing passenger ships en route directly to or from a port located outside the special area and to or from a port located east of longitude 28˚10′ E within the special area that does not make any other port calls within the special area.

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.