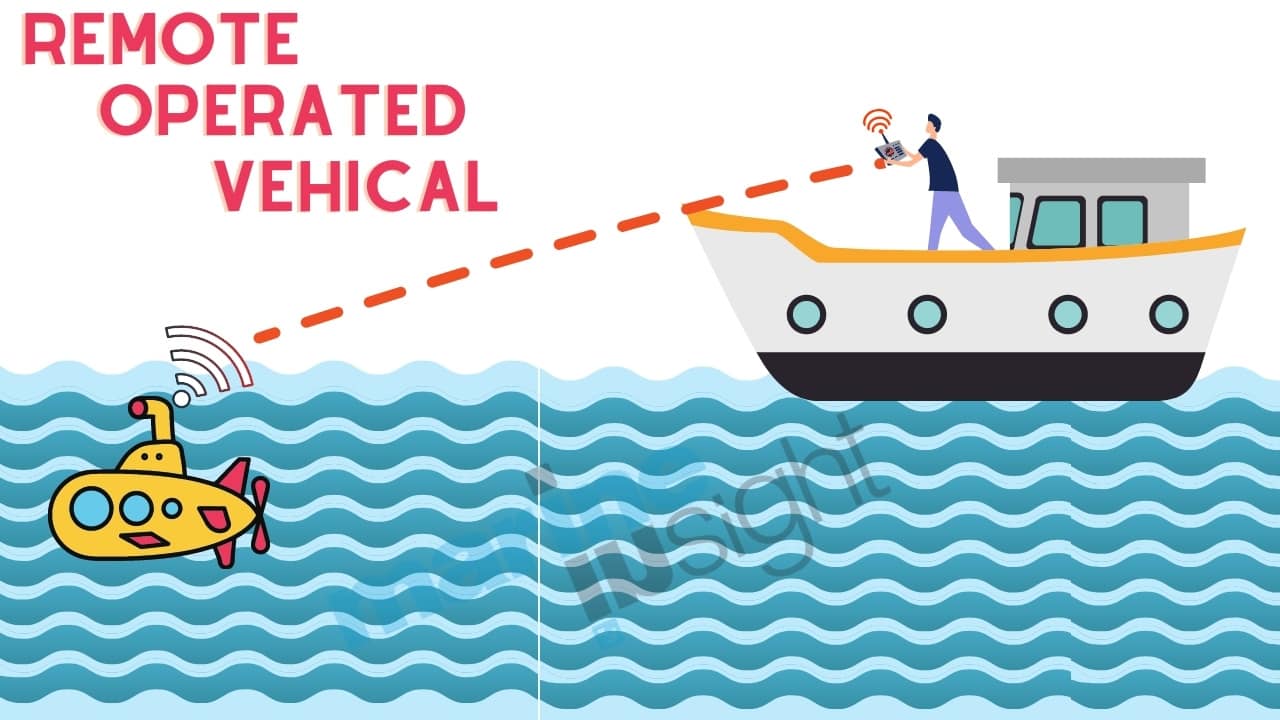

A remotely operated underwater vehicle also called an ROV, is unmanned and usually tethered to the operator. It is an underwater robot that collects data about the underwater world about subsea structures or geological formations like hydrothermal vents. It uses a Remote pilot and automated control technology, making it safe and convenient to operate.

Observation-class ROVs are used for ocean exploration and provide hd images and high-definition video for research and study purposes. The uncrewed vehicle is fitted with additional equipment like water samplers, manipulator arms, etc. Modern ROVs have 8-hour battery life.

An optical cable establishes a connection between the operator and the remotely operated vehicle, which enables its movement.

ROVs are incredibly complex and serve various purposes, from exploration and unmanned expeditions to research and sporting events. They are used by scientists, zoologists, botanists etc. Many industries, like aquaculture, agriculture, etc., use these devices for regular infrastructure inspections and repairs.

In this article, we will look at some of the salient features of ROVs, their usage, categorisation, preparation, launching, operation, and shortcomings.

An ROV is essentially a robot that can operate underwater. It works like a miniature submarine, but without the people using it from onboard.

It works wirelessly or through a wired connection, although the latter is more common. Several subsystems together make up the incredibly complex ROV.

The various components that form the broad operating mechanism of the ROV are-

1. Electrical systems (wiring and circuitry),

2. Mechanical structures,

3. Sensors and appendages, and

4. Task-specific structures.

The base frame on which all these systems are supported is the skeleton of the ROV. It is made as light as possible to prevent additional weight and drag during motion.

It is covered with a Manifold structure to prevent accidental damage to the internal components. There are holder clips along its frame members to support wiring and other electrical circuit components.

The skeleton is built to withstand impacts termed as “severe” and uses the triangulation principle of rigid mechanics. To understand how triangulation works, consider a square frame.

Any force at a vertex would lead to buckling and collapse of the frame. Instead, a diagonal member is introduced, providing additional tension strength.

By just adding a single member, the strength is increased across the frame. An X-joint is included in fragile areas, with two diagonal members for added strength in tension and compression.

The electrical systems refer to the wiring and circuitry that make up the heart of the ROV. The only reason they are so helpful and can be used in various fields is the highly robust and complex nature of the electronics outfitted on them.

The primary components include the main motherboard and processing unit, where instructions are fed from a controller and then converted into a physical output.

The controller is manually operated in most cases, and autonomous underwater vehicles (or AUVs) are scarce in this field owing to the various challenges presented.

Signals from the controller input are either wired or wireless based on the level of innovation and design. It may also be task-specific. For instance, a wired robot may get entangled in an underwater wreck site.

On the other hand, a wireless signal may be blocked as the robot heads deeper into the wreckage. So, a careful evaluation of the working conditions and possible hazards should also be done.

Once the signal reaches the onboard receiver, it is conveyed to the mechanical systems. The main system is propulsion, in the form of miniature and specialised marine propellers.

They are powered by small servo motors housed in waterproof casings, the propellers number 2 between 3 to 5 blades per shaft. They can be operated in both clockwise and counter-clockwise directions to create steering.

Some advanced ROVs in wreckage analysis and deep-sea exploration also have swivel jointed propellers. These are rarely used and are more costly than their fixed counterparts. It is only required in situations where very high precision is required.

Sensors and appendages form the very core of the ROVs functionality. The most common equipment includes cameras, depth gauges, temperature, and internal system sensors.

The operator uses cameras since they must have eyes on their surroundings. Depth gauges ensure that the ROV is at the required depth and does not descend into a high-pressure zone.

Temperature zones detect how the water temperature changes and help see subsea thermal vents and thermoclines. Lastly, internal system sensors ensure that the ROV functions perfectly and that all systems work as required.

Task-specific modifications make an ROV customisable and usable in various fields. For instance, historical exploration and wreckage visits can be used to collect artefacts with mechanical arms and tools.

For Subsea geological exploration, the ROV can be fitted with rock cutting tools to extract samples for analysis. For mapping the seabed, it is equipped with LiDAR, SONAR, or RADAR to ping and receive reflected waves off surface elevations and valleys.

Although a primary camera is usually there, they may be specialised cameras capable of thermal imagery, high precision photography, macroscopic lenses etc.

The choice of materials is critical to an ROV. The frame must be light enough not to affect the vehicle’s performance and strong enough to withstand mild to severe impacts.

Electrical systems must be encased in insulated coatings and housed in waterproof containers. Special attention must be paid to anti-corrosion materials to prevent any usage issues.

As the ROV spends a great deal of time underwater, there is a lower chance of rusting (lack of oxygen, which is necessary for rusting).

However, when on the surface, the probability of corrosion increases (dampness combined with atmospheric oxygen). For this, thorough drying must be undertaken, and the ROV must be stored in a dry and clean environment to prevent any fungal growth or corrosion.

The problem of marine growth is prevented by adding special paints that break down existing microbes and prevent new ones from attaching to the ROV surface when underwater.

ROVs are used for various purposes and are outfitted accordingly. This is why most unmanned vehicle manufacturers provide a basic skeleton or structure on which modifications can be made. The basic structure is known as the “frame” or “template” of the ROV. This section looks at the various uses to which these devices are put.

An underwater ROV is well-equipped with modern technology. It consists of a lighting system and a video camera to record a better subaquatic panorama and contribute to geology education and learning about sea life.

With continued developments in the arena of technology, the latest technical concepts are being imparted to remotely operated vehicles to amplify their original capacities to a greater extent. Extra machinery can comprise a static camera, a water sampler or even a manipulator.

Moreover, a remotely operated underwater vehicle can incorporate advanced instruments for appropriate measurement and evaluation of current temperature, light penetration and water clarity.

These are commonly used in scientific and exploratory ROVs to learn about the underwater environment. Chemical analysers also study water’s specific makeup or composition at various locations and depths.

ROVs or underwater robots were primarily invented to serve an industrial purpose regarding regular pipeline inspection (both interior and exterior) and to conduct structural testing methods on specific platforms from various offshore locations.

These ROVs are even helpful for exploring oceanic water wreckage sites and historical ruins. The ROVs cater to the needs of numerous science expeditions and several educational programs at aquaria.

Underwater ROVs can be distinguished into various classes by evaluating their weight, power, abilities and sizes. The Micro ROV is small-sized and weighs below 3kg.

The primary classifications used are as follows:

1. Micro ROVs

2. Mini ROVs

3. General ROVs

4. Inspection Class

5. Light Work Class

6. Heavy Work Class

7. Trenching and Burial ROVs

These attributes enable the ROV to explore tiny cavities or pipeline cracks, which is physically impossible for a diver to achieve.

The Micro ROV is small-sized and weighs below 3 kg. These attributes enable the ROVs to explore minuscule cavities or pipeline cracks, which is physically impossible for a diver to achieve

On the other hand, the typical Mini underwater ROVs have a standard weight of around 15kg. It takes just one person to efficiently operate it from a boat and carry out an underwater expedition.

The micro and mini categories of remotely operated vehicles can be termed an alternative “eyeball” as they do not participate in intervention undertakings.

The General ROV type is usually below 5 HP (propulsion) and comprises three-finger manipulators, like in the old RCV 225. These are specially built to aid in light survey tasks, as these usually bear a sonar unit.

The standard underwater depth is around 1000 meters, but one ROV has been upgraded to even traverse to 7000 meters.

The Lightwork class remotely operated vehicle is generally below 50 HP and can support several manipulators. These ROVs allow a maximum working depth of 2000 meters. Polyethene, a kind of polymer, is used in construction which varies from the typical aluminium alloys or stainless steel.

The Heavy workplace machine supports below 220 HP with two manipulators and can achieve a depth of 3500 meters.

These ROVs can have a lifting payload of over 5,000 kilograms. They can also be modified to work with multiple manipulators. The most common application of the heavy work class is in deep-water installations and subsea tie-ins.

The Trenching ROV offers a 200-500 HP range and can be utilised to 6000 meters. While most propulsion systems on these ROVs function below 500 HP, there are underwater vehicles that may function at powers of nearly 600 HP or more.

They are commonly used in cable laying, the safe creation of seabed trenches, and the partial or complete anchoring (burial) of subsea components used in the oil and gas industry.

Lastly, there is another classification of submersible ROVs based on how they are launched. There is a system known as Tether Management System (or TMS) that controls the payout for the umbilical cord that delivers power and control to the ROV. It is known as a free-swimming vehicle when it is directly connected to the ship or observation platform.

In such cases, it is neutrally buoyant. On the other hand, some ROVs are stored within compartments called garages that are lowered into the ocean.

During the launching, the ROV ejects from the submerged compartment and has its rope connected to the garage, NOT the ship. The choice of the launching system depends on usage, depth, function, and geographical factors.

The size range of a remotely operated vehicle is imposing, as it may vary from a small bread box to a minor truck. Preparing an underwater vehicle launch can be straightforward as the robot can be merely dropped into the water from the vessel.

The recovery procedure may involve big windlasses to uplift the robot from the water. Generally, A-frames are available to swing over the ROV safely onto the deck.

Different structures called “garages” are sometimes present, which are lowered to the rear end. These “garages” can act like a temporary yet secure den, and the ROVs can return once the expedition gets over.

The occasional excursions carried out by remotely operated vehicles are considered much safer compared to the usual diving expeditions, which can lead to physical injury or even death.

A remotely operated underwater machine can prove to be highly efficient when dealing with a submersible, as the cutter blades or the manipulator’s arm can come in handy while rescuing the submersible if it is stuck and unable to move freely.

Another drawback of submersible ventures is that bad weather conditions can be a significant hindrance, whereas a remotely operated vehicle can remain unaffected. As an added utilisation, research can initially submerge the ROV into the water to explore the detailing of the particular underwater site and then decide if it is safe enough to send a submersible.

Before ejecting the ROV from the side of the ship or launching the platform, the ROV is gently lowered into the water. It is not allowed to splash because of the risk of damage to the sensitive equipment on board. Windlasses may be used here, or if the freeboard isn’t too high, it may be manually lowered by hand.

A moon pool may be used in choppy waters that increase the risk of damage during splash zone entry. Moon pools are enclosures within a hollow vessel with the water surface at its lower end.

A column of water is created in which the water is relatively steady. Dampers are also used to reduce the heaving motion to prevent resonance-related damage. ROVs can be lowered through the moon pool in poor weather conditions.

Amongst well-known underwater ROVs, the Ventana runs on hydraulic power and can traverse to a depth of 1850 meters. The Ventana is manipulated from the RN Point Lobos ship deck.

On the other hand, the MBARI franchise purchased the ROV Doc Ricketts way back in 2008, which offers an incredible capacity of going deep down to a depth of 4000 meters.

This remotely operated vehicle has undergone constant up-gradation ever since. The Doc Ricketts served as a magnificent replacement to the earlier ROV Tiburon, which could also travel down 2.5 miles.

These unique submarines have enabled easier exploration of several deep-sea gas and oil reserves. Many oil reserves were hard to locate by using the divers and hence caused a major commercial setback.

Interestingly, the undetermined locations of famous shipwrecks like the RMS Titanic, USS Yorktown, SS Central America, and the German warship Bismarck have been discovered due to some help from the ROV industry.

In the case of SS Central America, the remotely operated underwater vehicle has also been able to retrace and gather essential materials from the seafloor of the shipwreck.

Shortcomings

The preferred design is a high-power signal that can control ROVs across a considerable distance. It will have a more extended range than currently possible with tethered structures. However, high power and frequency may affect marine life.

The other alternative is a low-power primary signal coupled with several amplifiers at regular intervals to create a more extensive range for the ROV.

Although it will be more expensive, it is preferred from an ecological viewpoint. Unfortunately, the issue with the low power option is that it would cause cluttering of the sea surface due to a larger number of amplifiers required to function.

A massive setback of a remotely operated underwater vehicle is that it lacks human presence, making it challenging to execute visual surveying down underwater. The car remains attached to the main boat above water through intricate wiring, leading to a restriction of free movement.

Research and innovation are currently being undertaken in the field of wireless control for ROVs. The proposed design suggests two main models for implementing this control.

The preferred design is a high-power signal that can control ROVs across a considerable distance. It will have a more extended range than currently possible with tethered designs. However, high power and frequency may affect marine life.

The other alternative is a low-power primary signal coupled with several amplifiers at regular intervals to create a larger range for the ROV. Although it will be more expensive, it is preferred from an ecological viewpoint.

Unfortunately, the issue with the low power option is that it would cause cluttering of the sea surface due to a larger number of amplifiers required to function.

A remotely operated underwater vehicle also called an ROV, is unmanned and usually tethered to the operator. It is an underwater robot that collects data about the underwater world about subsea structures or geological formations like hydrothermal vents.

Observation-class ROVs are used for ocean exploration and provide hd images and high-definition video for research and study purposes. ROVs are incredibly complex and serve various purposes, from prospecting and unmanned expeditions to research and sporting events. They are used by scientists, zoologists, botanists etc. Many industries, like aquaculture, agriculture, etc., use these devices for regular infrastructure inspections and repairs.

It uses a Remote pilot and automated control technology, making it safe and convenient to operate. The uncrewed vehicle is fitted with additional equipment like water samplers, manipulator arms, etc. Modern ROVs have 8-hour battery life.

The Ventana runs on hydraulic power and can traverse to a depth of 1850 meters. The Ventana is manipulated from the RN Point Lobos ship deck. MBARI franchise purchased the ROV Doc Ricketts way back in 2008, which offers an incredible capacity to go down to a depth of 4000 meters.

They have enabled easier exploration of several deep-sea gas and oil reserves. Many oil reserves were hard to locate by divers. Also, undetermined locations of famous shipwrecks like the RMS Titanic, USS Yorktown, SS Central America, and the German warship Bismarck have been discovered due to the help of the ROV industry.

You might also like to read

Disclaimer: The author’s views expressed in this article do not necessarily reflect the views of The Marine Learners. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and The Marine Learners do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendations on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and The Marine Learners.

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.