Turbine generator is a popular source of clean power generation on ships as they don’t use any type of fuel i.e. heavy or diesel oil. Steam is used for power production in case of turbine generators. Steam is an easy, environmental friendly and cheap form of fuel on ships. For turbine generators, the steam comes from the ship’s steam boiler plant.

In turbine generator, steam is used with high pressure to rotate turbine wherein the thermal energy of the steam gets converted into rotary motion. The turbine is connected to the alternator’s rotor; hence the rotary notion of the turbine is utilized to generate electric power.

On ships, the steam turbine can also be used as a direct propulsion plant, in which, the turbine shaft is connected to propeller shaft of the ship. Since the speed will be in thousand rpm, reduction gears and reduction systems are used to get a drop in propeller rpm.

The propelling plant of the ship can be driven by steam turbine through a slow speed motor. The turbine generator directly supplies power to these slow speed motors which are connected to the propeller shaft of the ship.

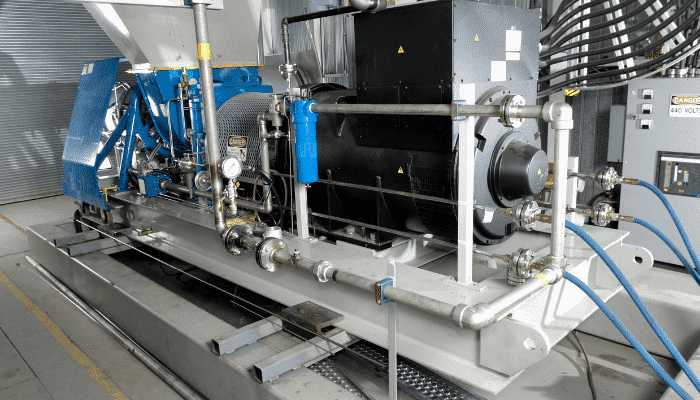

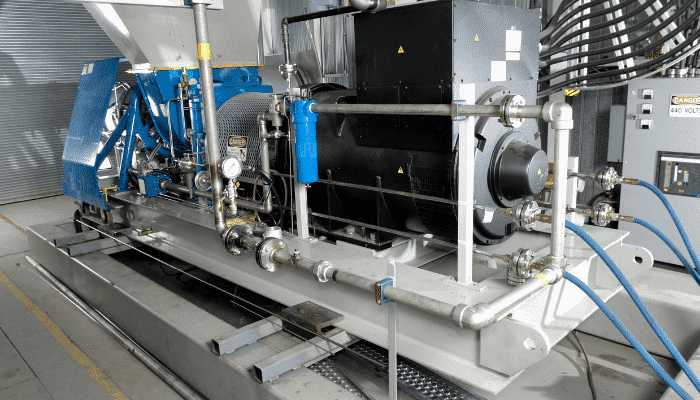

A turbine will act as a prime mover in turbo generator and is fitted on the same shaft as of the alternator’s rotor.

The alternator is used to convert the rotary motion of the turbine to electrical energy and its output is supplied to the main switch board of the ship.

The governor is used to control the speed of the turbine generator during starting, normal operation and shutting down. It controls the quantity of the steam inlet to the turbine generator.

Different pressure control valves are fitted in the steam line and are controlled using governor for the flow of steam from the ship’s boiler system.

The condensed steam, after the turbine is further cooled down, is pumped back to the cascade tank by condensate pump.

The steam turbine shaft is provided with glands wherein steam is sprayed at a pressure of 0.3~ 0.5 bar so that the vacuum inside the turbine casing doesn’t drop.

The heat exchanger acts as a condenser to cool down and condense all the steam from the turbine into water so that it can be pumped back to the hot well.

A vacuum pump header tank is provided to cool down the vacuum pump as the later deals with high temperature steam.

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.