[Updated]Mooring operations are carried out by the Chief Officer (for the forward station) and the Second Officer (for the aft station); however, it varies among companies wherein sometimes the Third Officer executes the forward station so that the Chief Officer may be with the Master on bridge to hone his skills with regard to ship handling when mooring operations are in process.

A cargo vessel’s main earning potential is tested not just by the safe transport of goods while in open sea but also by the vessel’s turnaround time while in port. While the handling of the cargo itself is prime in assessing the efficiency of the operation, mooring also is an integral part of ensuring that the former runs smooth.

An efficient port and cargo operation of a ship is what every ship operator expects from its deck crew. The first and foremost operation performed by the deck crew as the ship reaches the port – the mooring operation is also one of the most difficult and dangerous jobs on ships.

There have been several cases reported in the past about accidents during mooring operation that has led to severe injuries or deaths of seafarers. The mooring ropes/wires that are dealt with on board are not the average ropes and if strict caution is not exercised when handling them, the chances of injury are very high and can cause severe damage to both the ship as well as the personnel.

The mooring area on a ship comprises of forward and aft parts of a vessel where winches are installed to pull the ropes from the tug and jetty bollards.

The Mooring area is equipped with several equipment and systems such as winches, hydraulic motors, bollards, piping valves, anchor chain etc. All these parts work in conjunction to ensure that there is no damage when such an operation is carried out.

All the above points are considered by the supervisor i.e. Chief officer or 2nd officer while preparing a mooring operation beforehand, under the obvious supervision of the Master

From the above-listed points, two important and dangerous phenomena which are responsible for maximum causalities in mooring of a ship and which are also considered as death traps are-

[the_ad id=’172861′]

The highest number of injuries and deaths during a mooring operation on a ship are due to the parting of the rope or wire hitting back to a crew member standing in the area of the rope. The area traveled by the parted rope having a force enough to kill a person on its way is known as the snap back zone.

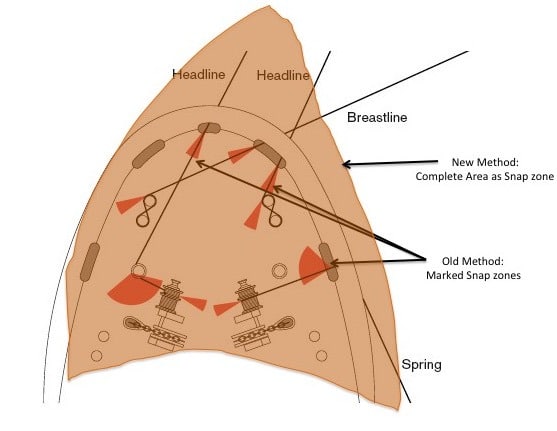

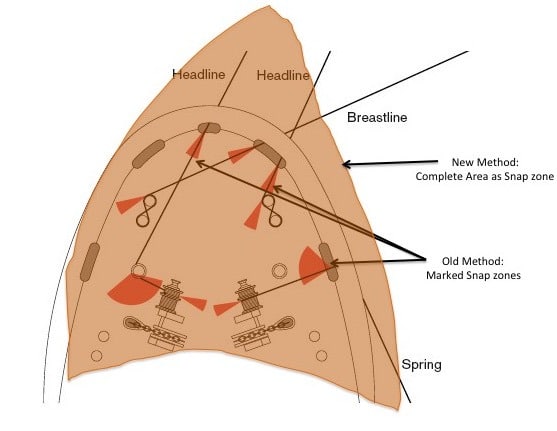

When ropes are pulled straight then the snap back zone is minimal but if the ropes are turned in bollard or roller then the snap back area increase. Previously, for the safety of seafarers working on this area, snap back zone markings were provided as shown in the diagram below:

The marking of snap-back zones on the deck, although convenient and simple, does not reflect the actual complex snap-back zone and may lead the seafarer into a false sense of security that they are safe as long as they aren’t standing in the highlighted area. The latest version of the COSWP (2015 edition) has revised its guidance on snap-back zones and now dissuades the marking of snap-back zones on the deck. It recommends that the entire mooring deck should be considered as a potential snap-back zone and clearly, visible signage must be displayed to warn crew.

A ship has to be pulled by tugs or by ships own winches for making it close to the jetty for berthing. This requires strong ropes and wire to be stretched in tension for pulling the ship. Every rope and wire has got its own endurance limit above which it will fail and part off. The endurance limit will get reduce if the rope is old or not maintained properly.

The rope will break or part when it is in tension due to pulling action and when these parted rope swings back in its snap back zone and hits a person standing there, it can be a deadly blow

The crew performing the operation must be thoroughly trained and qualified with the snap back area. The ship fore and aft parts i.e. the entire mooring deck should be considered as a potential snap-back zone and clearly, visible signage must be displayed to warn crew.

Mooring ropes are long and heavy ropes stored on board ships in coil form. When these ropes are under operation, they tend to form a coil or ring shape naturally known as rope bight.

If a person involved in mooring operation comes under this rope bight, the pull of the rope can drag him over the ship or smash him in the hard deck over machines. Several injuries and deaths have been reported due to crew unaware of standing over bight and dragged by the rope.

[the_ad id=’173168′]

One must remember prior to the start of such an operation to have all the requisite ropes ready for operation laid out on deck. The winches should be checked in advance for smooth operation and any entanglements must be fixed. The deck must be checked to be free from stray items and any such items should square -up. It is imperative to remember that in cold weather, there is a chance of slipping due to ice accumulation and a very strict safety policy must be followed in that case.

Remember, bights don’t always look like bights. Safety of human life on the ship must be the first priority of all operations performed. Life is precious, always think about Safety First.

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of The Marine Learners. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and The Marine Learners do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and The Marine Learners.

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.