Self Contained Breathing Apparatus, also known as SCBA, is a necessary protective gear that is worn by paramedics, firemen, and people working on ships and oil rigs.

As the name goes, the breathing apparatus has all the necessary equipment fitted into it that will allow the rescue professionals to carry out their work without any interruption and with utmost safety.

There are two major types of SCBA that are in use today – the Open Circuit SCBA and the Closed Circuit SCBA. The main difference between the two is that the former one is used for rescue operations that tend to be very long.

In this type of SCBA, the air is continuously re-processed or recycled so that the wearer of the SCBA gets a continuous supply of air. In the second variety, the oxygen is compressed to fit into air cylinders. These varieties of SCBA are used for shorter rescue operations.

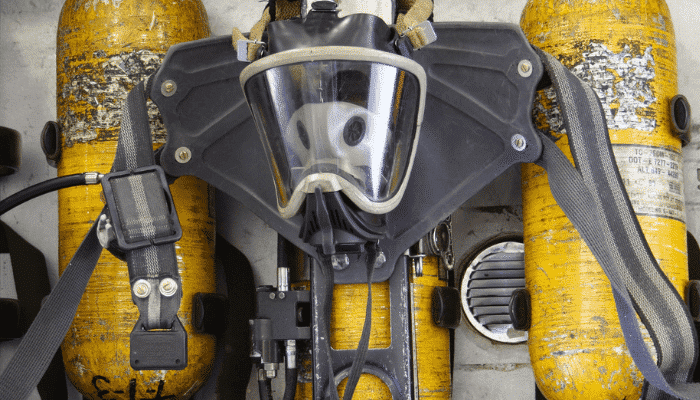

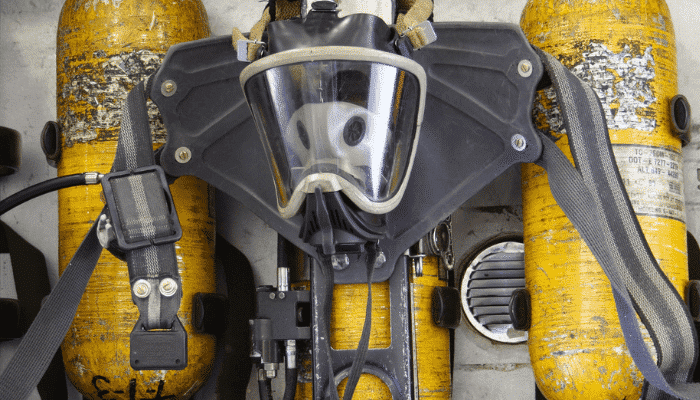

The SCBA used on board ship is of the open circuit type mostly. In this, the exhaled air is discharged to the atmosphere while air from the cylinder is made available for inhalation. The equipment consists of:

The first and foremost presence in the air-breathing apparatus is that of Air Cylinders. In the open-circuit SCBA, the air cylinder is known as the re-breather which recycles the air (as mentioned above).

Air cylinders, on the other hand, are filled with oxygen in a compressed form that enables a rescue professional to go into areas that are filled with smoke and fire and free the trapped people successfully.

The air cylinders in the breathing apparatus need to be continuously checked after the rescue operation is carried out so that they do not end up being empty the next time a rescue operation needs to be carried out. There are also extra air cylinders that are provided for the people who have been trapped and rescued.

The second-most important presence is that of a Protective Hood. Such hoods are designed in a way that they cover all the parts of the face, have an eye-covering (visor) that enables a person to see and also allow the required oxygen to pass continuously. They also have tubes attached to ensure that the air passes continuously.

The Portable Transporting Bag is also important equipment of the breathing apparatus. It can be filled with air cylinders, hoods and any other protective equipment that would be necessary for the rescue operations. The bag is made up of a material that would be resistant to damage-causing factors and thus can be effectively used in any sort of emergency situation.

The final breathing apparatus equipment is the Portable Hauling Bag. The main difference between this type of carrying bag and the one mentioned previously is that in this bag, the extra weight of the necessary items can be carried.

It is used for the purpose of getting the SCBA equipment from the headquarters of the rescue professionals to the place where the incident has actually occurred. It is only at the accident site that the equipment is transferred from this bigger bag to the Portable Transporting Bag.

A breathing apparatus has changed the entire rescue operation process, making it simpler and safer. More and more lives can be saved because of the portability factor of SCBA. It, therefore, becomes important and relevant to acknowledge and appreciate the worth of the SCBA in today’s times.

| Degrees of work | Air consumption

(litres/minute) |

Duration of the cylinder in minutes (1200 litres capacity in minutes) | Duration of the cylinder in minutes (1800 litres capacity in minutes) |

| Resting | 8-12 | 150-100 | 225-150 |

| Light Work | 12-20 | 100-60 | 150-90 |

| Moderate Work | 20-40 | 60-30 | 90-45 |

| Heavy Work | 40-60 | 30-20 | 45-30 |

Nominal Working Duration = (Fully Charge Cylinder Capacity) – 10

40

We subtract 10 as 10 minutes is when the alarm starts ringing and it is a safe period that must be taken into account. So a 1200 litres cylinder will last for 1200/40 = 30 minutes minus the 10 = 20 minutes

Nervousness and excitement can cause an increased demand for oxygen and a proportionate increase in respiration rate.

Open the cylinder cradle by squeezing the two sides of the cradle lever and open the cylinder strap. Line up the cylinder valve with the reducer valve hand wheel and turn the handwheel counterclockwise until hand tight. Hook cylinder strap over the cylinder and pull down the operating lever onto the tension spring to be clipped to place.

To attach demand valve assembly to facemask- line up assembly with the red bypass valve knob upwards with the centreline of facemask and turn assembly clockwise through 90 degrees until it clicks into place

The SCBA sets must be checked routinely and maintained to keep them in working order at all times. Check the backplate and the shoulder/waist straps for any damage and keep these straps and belts fully stretched.

Check the facemask straps and other rubber parts for any deterioration. Wipe the mask with a mild disinfectant and rinse under running water. Wipe dry, always. Perform pre-use checks after every maintenance.

The SCBA is a vital piece of equipment that must be given very high importance in terms of maintenance. Whether it be fire fighting or entry into enclosed spaces, the SCBA is what comes hand in such situations.

Visual inspection must be carried out thoroughly every month on these sets. Every year all the valves, sealing and speech membranes must be checked.

The exhalation disc must be replaced every two years and every five years the complete apparatus should be submitted for a full-service check for overhauling.

You might also like to read:

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of The Marine Learners. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and The Marine Learners do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendations on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and The Marine Learners.

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.