The confabulation “General Cargo vessel “was used for all types of vessel in around the late 1500s when the international trade began to hit the global shipping market.

All vessels at that time were made with the same elemental concept, without considering the fact that different cargoes needed different degree of care and attention as there was a little way of specialisation.

However, over time, the vessels started becoming more evolved. The need for specialisation was soon seen worthwhile.

Another reason was also that the increase in international trade demanded a high quantity of the single commodity to be transported from one place to another. This was the primary reason for the introduction of different ship types.

Primarily the transportation of bulk liquids began in the year of the late 19th century when the discovery and expedition of oils began.

At that time, tankers emerged as the main mode of transportation to carry bulk liquids from the refineries to the global market. On the way, as different energy products emerged, the need for a different type of tankers came into the real picture.

Presently, a variety of products such as crude oil, finished petroleum products, liquified natural Gas, Chemical, Edible oils, wine, juice, molasses are the linchpin of the global shipping industry. Tankers play a major share of more than 33% of the worlds fleet tonnage.

Tankers are a very vital cog in the entire global marine cargo operation. Mammoth and huge, they help ferry bulk loads of commodities and materials across the world which keeps maintaining continuity in the other industrial and commercial operations.

Tankers however are not just restricted to one particular type or variety. There are many varied types of tankers that are used in the process of oceanic cargo transportation. This classification of tankers can be based on several factors.

In this article, we will see the extensive categorisation of various types of Tankers in terms of Use, construction & and Size.

However, there are two categories in which shipping tankers can be classified:

-By Type/Purpose

-By Size

1. Oil Tankers: Oil tankers, as their name suggests, carry oil and it’s by-products. Oil tanker, however, is a generic terminology and includes not only crude oil but also petrol, gasoline, kerosene and paraffin.

An Oil Tanker is designed to carry Petroleum products in bulk. These vessels carry a wide range of products ranging from Crude oil to Refined products. Their size is measured in tons or DWT. Its size ranges from 55,000 DWT to VLCC’s of over 300,000 DWT.

Most of these Oil tankers are owned and operated by commercial oil importers or exporters and even by governments. Due to their immense size, they have become quite cheaper to transport petroleum products from one place to another. Literally, for a typical Oil tanker, it costs around 2-4 cents per Gallon only.

Oil tankers are further sub-divided into two main types: product tankers and crude tankers:

– Product tankers are used to transport the above-mentioned petroleum-based chemicals

Product Tankers are used to carry refined oil (various grades) to the point near the engrossing market. They are smaller in size as compared to the Crude oil tankers.

The tanks here are coated with epoxy that is used to protect the cargo and also helps in tank cleaning.

– Crude tankers are specifically used to transport crude oil from the excavation site to the crude oil refining industrial plant

These tankers move a large quantity of unrefined crude oil from its elicitation point to the oil refineries, where they are refined and various grades are products are extracted and distributed later on.

These vessels are much larger in size than the other variants of oil tankers. For example, moving crude oil from oil ell of Pointe Noire, Congo to the refineries on the coast of the United States.

Gas Tankers

Tankers that are specially designed to carry Gas in bulk are called Gas tankers. They are specially designed to carry different forms of gasses.

Technically these types of vessels are more on the cutting edge than any other type of vessels such as Bulkers, Containers and Other variety of Tankers. They are mostly built in the shipyards of Korea or Japan.

As per the type of cargo carried and the carriage predicament, these can be classified into five categories as named below:

Fully Pressurised Ships

These type of Tankers are the cinch type of gas carrier compared to all of its other varieties. Cargo herein is carried in the ambient temperature. They have “C type” of tanks which are made in Carbon steel with an emblematic design pressure of 18barg. There are no thermal insulations or any other plants. The cargo can be directly transferred by the pumps or compressor of their own. These types of the vessel usually are smaller in size as because of the design pressure, the tanks are extremely heavy.

Semi-Pressurised Ships

These are very similar to fully pressurised ships in term of the tanks construction and structure, but they are designed to carry gas at a maximum working pressure of 5-7 bars.

It can be used to transport a wide variety of gas cargo in bulk and can be usually seen in the busy coastal areas around the Mediterranean and Northern Europe. Due to its cargo handling flexibility, semi pressurised gas tankers are most popular among the operators and owners.

Ethylene Ships

This variant of Gas carriers are built for unambiguous trades but also have arrangements to carry LPG’s or Chemical Gases. Their cargo carrying capacity is between 1000-12000 m3. They too have Type C pressure tanks. The Thermal insulation and liquefaction are fitted on this variant of gas tankers.

Fully Refrigerated LPG Ships

These tankers carry Liquified gases at low temperature and atmospheric pressure. They have a very significant prismatic shaped cargo tanks made up of 3.5% nickel steel, which allows them to carry cargo at a temperature as lower as -48°C.

As per the cargo containment system, this type of vessel can be further classified as:—

1. Independent tanks with single hull but the double bottom and hopper tanks

2. Independent tanks with double hull

3. Integral tanks (incorporating a double hull), and

4. Semi-membrane tanks (incorporating a double hull)

LNG Carrier: The LNG Carriers are those tanker ships that are used to cargo LNG or Liquefied Natural Gas. These types of tankers require careful and delicate handling owing to the precariousness of the material they carry. Statistically speaking, there are around 193 LNG tankers that are currently under operation.

LNG(Liquified Natural Gas) Carriers are specifically designed to trade a high volume of LNG. These ships have a cargo carrying capacity between 125000 m3 to 135,000 m3.

Their average life span could be somewhere between 20-25 years. LNG is carried at its boiling point, which is -162°C. In the years, there has been a lot of development in the containment system of LNG Vessels.

These carriers are fitted with independent cargo tanks or with membrane tanks.

Vessels can be classified into four categories in term of the cargo containment system:

Moss( Spherical-Type A)

This system is named after the company which designed them, i.e.; The Norwegian Company Moss Maritime. Most of these type of vessels have 4-5 tanks. These tanks here have a working pressure of 22 kPa(3.2Psi) which can be increased in case needed.

IHI(Prismatic-Type B)

The self-supporting prismatic type B tank is designed by Ishikawajima-Harima Heavy Industries which are employed in only two vessels. They cater to the problem of “sloshing “over the membrane LNG carrier tanks. Because of the several incidents in the past, These tanks were constructed to sustain internal accident damage due to internal equipment releases.

TGZ MARK III

These are the membrane type design which is designed by Technigaz. This consists of waffles, the primary barrier is made up of stainless steel of 12mm thickness and the secondary membrane followed by a primary insulation which is anew with secondary insulation. All these barriers are supported by the ship’s structure from outside.

GT96

This design designed by Gaztransport consists of primary and secondary membranes made up of a material Invar which has no thermal contraction. Here the plywood boxes filled with perlite is used for insulation which is flushed with nitrogen gas.

CS1

The combined system no.1 was designed by Gaztransport & Technigaz.In this design, the best two components, namely Mkll and No96 systems are used. Here primary barrier is constructed up of Invar and secondary from Triplex. Till now only 3 vessels are made using this membrane system by 1 shipyard.

3. Chemical Tankers: Chemical tankers are those cargo tankers which transport chemicals in various forms. Chemical tankers are specifically designed in order to maintain the consistency of the chemicals they carry aboard them. These tanker ships are applied with coatings of certain substances that help in the easy identification of the chemicals that need to be transported.

Chemical tankers are tankers that are used to transport various liquid chemicals. Each Chemical Tankers transport the same kind of chemicals. They range from 5000 DWT to 35000DWT in size. The size is very smaller of these vessels as compared to the Oil tankers due to the specialized nature of the cargo and the size restriction of the Ports and shore facilities.

It consists of various tanks which are coated with specialized coatings such as Phenolic epoxy or stainless steel or zinc paint. Type of coating of their tanks determines the suitable cargo(the chemical which can be carried.

Customarily Chemical Tankers can be classified into 3 categories as per their type:

TYPE 1

Products which possess very serious environmental and safety hazards which require maximum preventive measures to prevent any leakage of cargo comes under Type 1 Chemical Tanker.

TYPE 2

Chemical products with markedly severe environmental and safety hazards which require significant preventive measures to forestall any escape of such cargo can be classified as Type 2 Chemical Tankers.

TYPE 3

Chemical tankers which transport products with amply severe environmental and safety hazards which require a moderate degree of containment in a damaged condition can be referred to as Type 3 Chemical Tankers.

Most of these chemical Tankers are IMO Type 2 or Type 3 since the volume of IMO Type 1 cargo is limited.

4. Slurry Tankers: Slurry refers to all those materials that do not disperse or dissolve in water – otherwise regarded as waste materials. The slurry is used as a fertiliser and the slurry tankers help to haul slurry to areas where they can be put to productive use.

This type of vessel is used to carry frittered products where it will be economically useful., in general, is a by-product of refinery products which is very aromatic and forms a very small portion of the global fuel market.

These types of vessels are not ideal for shipping any other chemical products other than slurry itself.

5. Hydrogen Tankers: As the name suggests, hydrogen tankers are cargo tankers used for the shipping and transportation of liquefied hydrogen gas.

These tankers are specifically designed to carry Liquified hydrogen gas in bulk. They can’t be used to carry any other purpose. Kawasaki heavy industry was the first to design a Hydrogen Tanker.

6. Juice Tankers: As the name suggests, these tankers were specifically designed for the carriage of juices. Juice tankers or more specifically orange juice tankers which are used for the cargo carrying of orange juice in mass quantities.

They either carry concentrated or fresh orange juice, originating from Brazil to the other parts of the world. One of the biggest juice tankers is the Brazilian tanker, Carlos Fischer. However, other fruit juices carriers are also available.

These tankers have refrigeration, temperature controller and preservation plants, which helps them to keep the juice fresh at all times.

7. Wine Tankers: Transporting wine has become quite simpler and feasible in contemporary times as sleek tankers have come up which are used specifically to carry wine to their intended destinations.

These tankers are used in carrying wine from the place of production to their different destination. Wine tankers are for transporting already produced wine from one country to another country for packaging.jk

8. ITB (Integrated Tug Barges):

In this type of vessel, the stern is jagged into a special type of tugs which can easily be connected to the barge, establishing it as a single unit.

ITBs are prominently used in the eastern coast of the United States. These tankers are mainly tugs attached to barges leading to the formation of a single cargo carrying unit.

The carrying capacity of ITB’s is are not higher as a product or crude carrier but that capacity is enough for meeting the market demand. A number of barges can be connected to a single tug to increase the carrying capacity.

ITB’S can be categorised into two groups:

Pushing Mode ITB

These possess similar characteristics of a ship of proportionate size. It has a very comfortable seakeeping capability, stability and dynamicity. The tug here remains in the pushing mode throughout its voyage.

Dual Mode ITB

This type of ITB can operate in both the configuration either combined or as tow on a hawser, where tug can separate safely from the barge itself. It meets the stability criteria in aspects of weather, dynamic and towline pull.

As per the construction of hull, the tankers can be categorised into 2 categories. However, the IMO(International maritime organisation) has introduced reg 13F in Annex 1 of MARPOL, which mandates all the newly built Tankers of 5000DWT or more to have a double hull.

Single Hull Tankers

Single Hull Tankers have only 1 outer layer which is watertight and this layer runs throughout the structure of the vessel. This construction of the vessel has a greater threat to the marine environment. Single hull tankers are also more stable as compared to the Double hull tankers. A major problem of leaking ballast pipes are also considered as a danger in these kinds of vessels as the threat of contamination of the cargo is always present since the ballast pipes pass through the Cargo tanks of the vessel.

Double Hull Tankers

As the name defines, the double hull tankers have a double layer of watertight protection which runs throughout the length of the vessel. Both the inner and outer layers are present on the bottom as well as on the side of the vessel. Here the gap between both the hulls is used as ballast tanks for maintaining the vessels stability.

Though Double hull tankers possess less threat to the marine environment in case of accidents and are more snug, these vessels are not as stable as the single hull. The reason is that it increases the centre of gravity and reduces the metacentric height.

Some of the tankers shipping varieties in this category are as follows:

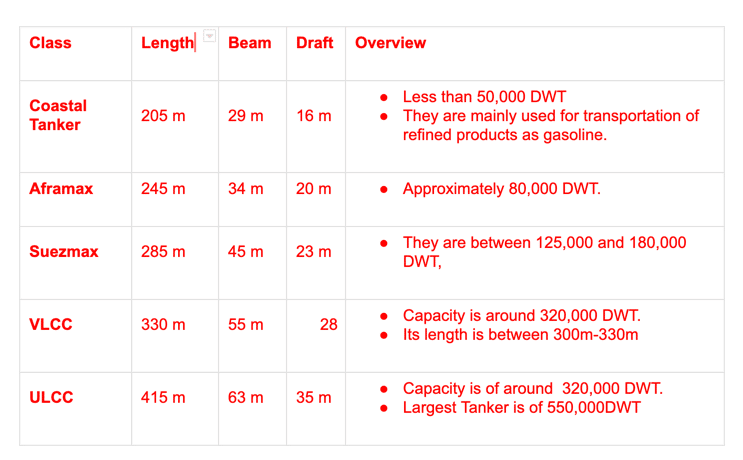

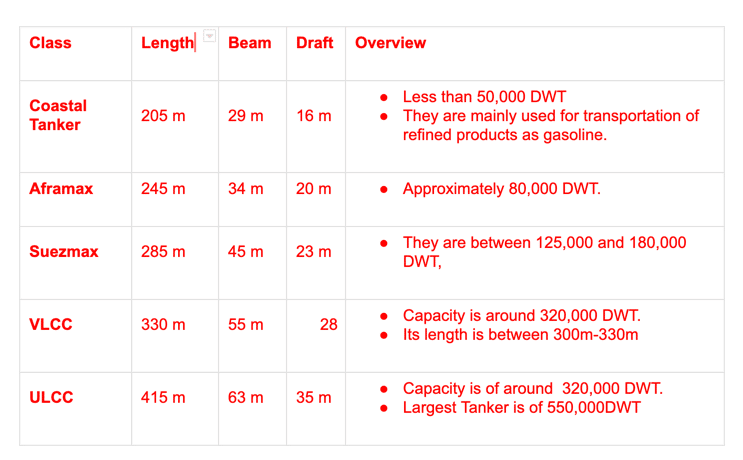

1. VLCC: Known as Very Large Crude Carriers, these tankers have a cargo carrying capacitance of 2, 50,000 tons. Know more about them here. (Link here)

2. ULCC: They are known as Ultra Large Crude Carriers and have a cargo hauling capacitance range up to 5, 00,000 tons. Know more about them here. (Link here)

3. Panamax: The classification of tankers that can pass through the Panama Canal is known as the Panamax. The cargo tankers which cannot be classified under this category owing to their size are known as the Post-Panamax tankers. (Link here)

4. Aframax: The Aframax cargo tankers are that type of tanker ships which are mainly used in the Mediterranean, China Sea and the Black Sea. These tankers have a dead weight tonnage (DWT) between 80,000 and 1, 20,000 tonnes.

5. Suezmax: Panamax tankers are named for vessels which can navigate through the Panama Canal. On similar lines, the Suezmax vessels are so called because of their ease in passing through the Suez Canal.

Although it is a known fact that many cargo ships cause oceanic pollution and degrade the marine environment, it cannot be denied that in the present day scenario, these tankers shipping offer the best possible transportation efficiency.

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of The Marine Learners. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and The Marine Learners do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and The Marine Learners.

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.