Fuel oil consumption calculation and recordkeeping onboard ships are some of the most critical tasks that the Chief Engineer is in charge of.

Fuel oil is provided by the charterers of the vessel and the Chief Engineer has to report to them every day with fuel oil consumption report, remaining on-board and requirements for the next voyage.

The applied method for measurement for the ship is briefly described in this article. The description explains the procedure for measuring data and calculating annual values, measurement equipment involved, etc.

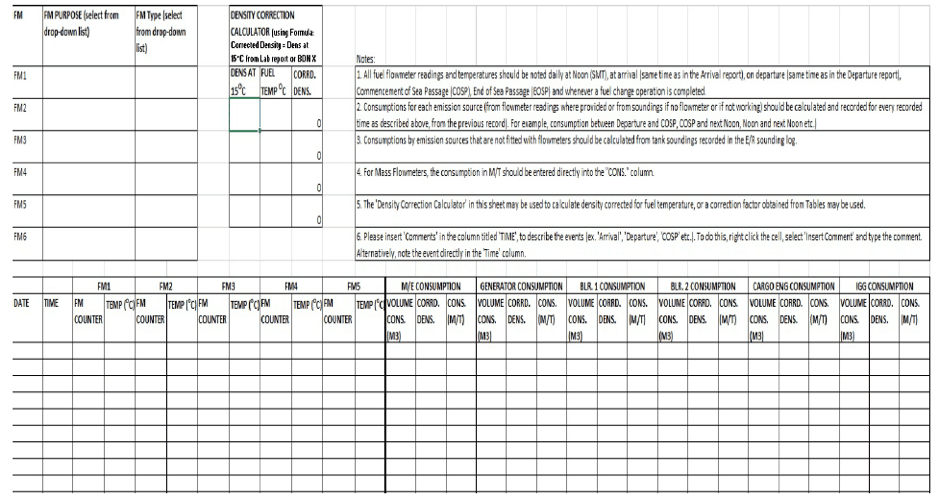

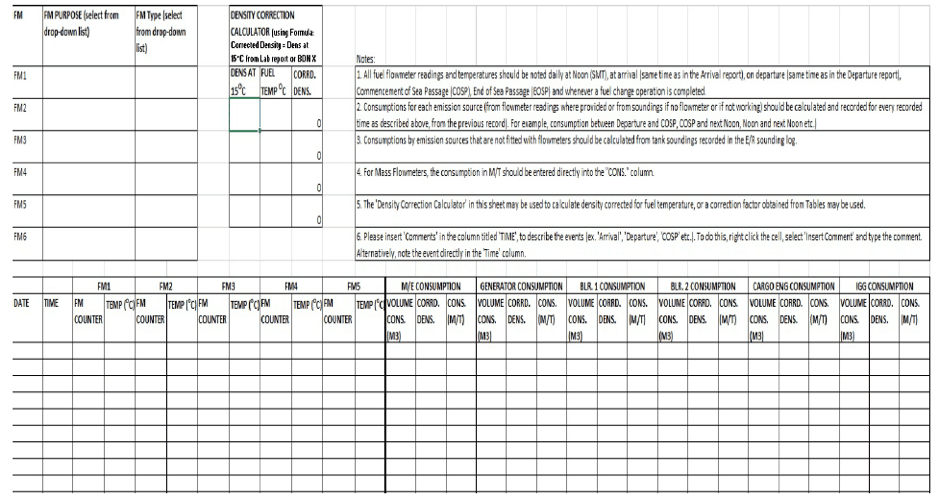

Where a flow meter is fitted on a pipeline supplying fuel to an emission source (main engine, diesel generator, auxiliary boiler, etc.), flow meter readings are the principal means of determining fuel consumption.

Flowmeter readings and fuel temperatures are to be recorded daily at 1200 hrs (noon) ship’s meantime, as well as at the time of Arrival (as noted in the Arrival report) and Departure (as noted in the Departure report), in the Excel spreadsheet, consisting of all correct calculation formulas.

The formula (Corrected Density = Density at 150C X [1 – {(fuel temp (0C) – 150C) X 0.00065}]) should be used to obtain the corrected density at the recorded fuel temperature. A calculation table has been provided for this purpose in the excel worksheet.

Related Read: 3 Important Calculations Every Marine Engineer Must Know On Ships

In addition to reporting fuel consumptions every noon and on arrival and departure of the ship, it is also necessary to record flow meter readings at the following events:

• At End of Sea Passage

• At Commencement of Sea Passage and

• When every fuel change operation is completed

Related Read: Fuel Oil Change Over Procedure for Ship’s Main and Auxiliary Engine

Fuel transferred from the fuel oil drain tank or fuel oil overflow tank back to the fuel/settling tank is to be noted in Position, Arrival and Departure reports. This amount will be automatically subtracted from the voyage fuel consumption.

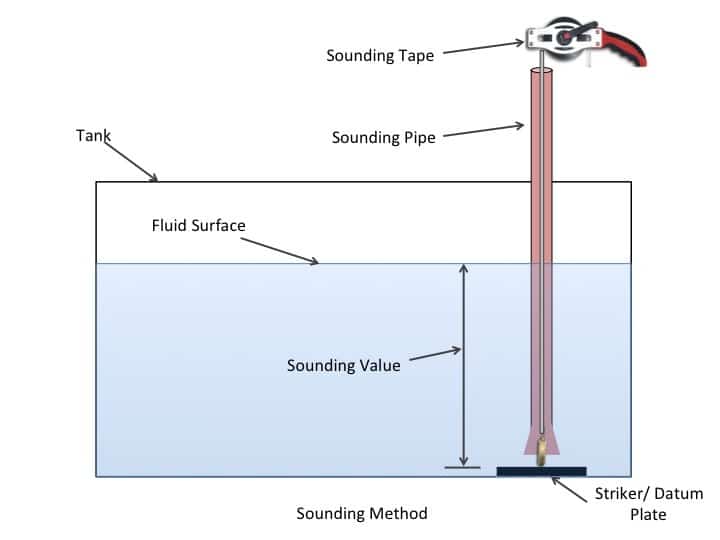

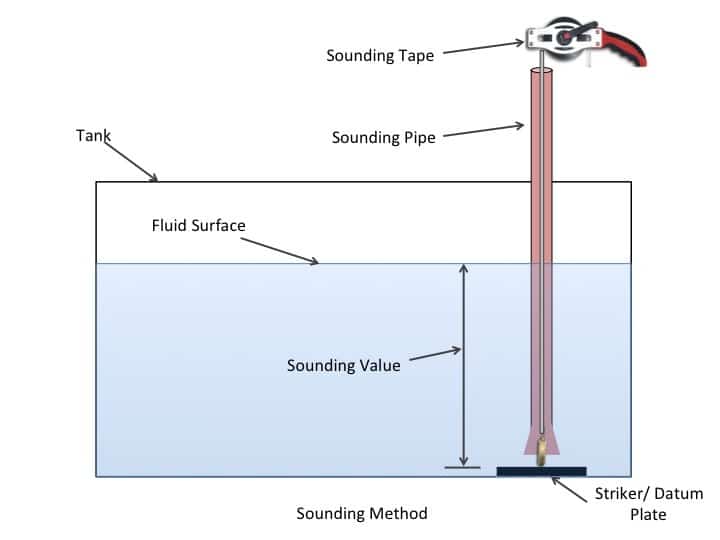

For emission sources that are not fitted with Flow meters or when the Flow meters are not operational, bunker fuel tank monitoring on board is to be done.

In this method, tank readings of all fuel tanks relevant to the emission source, using tank soundings/ullages or level gauge readings, are to be noted in the Engine Room Sounding Log. Consumptions are to be recorded in the Excel spreadsheet.

In addition, fuel quantities in all fuel tanks on board ship are to be determined periodically at least as per the following schedule.

Quantities may be determined by use of the fixed gauging system where available or by manual sounding:

• At every arrival of the vessel in Berth and at every departure from Berth. (This may vary with Company’s policy)

• Prior Bunkering / De-bunkering

• After Bunkering / De-bunkering

• Minimum Once every seven days

Related Read: 20 Points Engineers Onboard Ship Should Consider While Planning For a Long Voyage

Position, Arrival and Departure reports in the company’s reporting infrastructure for ships are the primary means of reporting MRV-related data, including fuel consumption, transport work, and other voyage-related data.

A position report must be submitted each day at 1200 hrs. (noon) ship’s time, when the ship is at sea or in port.

There must not be a gap of more than 24 hours (Ship’s Mean Time) between two position reports or between a position report and an Arrival report or between a departure report and the next position report or between Departure and Arrival reports.

Generally, if the gap is more than 24 hrs the user will not be able to submit the report and will need to submit the missing report (with a gap of less than or equal to 24 hrs.) first.

An Arrival report must be submitted for the first arrival in Port. ‘First arrival in port’ means, the first time (for a specific port/location) that the vessel is:

– All fast to a wharf/buoy moorings / SBM (if berthing directly, without anchoring), or

– Anchored (i.e. ‘brought up to anchor’) within port limits, or

– Anchored (i.e. ‘brought up to anchor’) outside port limits, or

– Anchored at a lighterage area, or

– All fast to a lighter vessel (if berthing alongside lighter vessel directly, without anchoring), or

– Arrival at a lighterage area (if drifting, without anchoring, while awaiting lighter vessel)

A Departure report must be submitted for the final departure from a port. ‘Final departure from port’ means a departure from the last:

– Wharf/buoy mooring / SBM (all lines cast off), or

– Anchorage within port limits (anchor aweigh), or

– Anchorage outside port limits (anchor aweigh at an offshore location), or

– Lighterage location (all lines cast off from lighter vessel/anchor aweigh)

Related Read: 7 Important Points For Safe Lightering Operations On Ships

An Arrival report for a specific Port or offshore location must be followed by a Departure report from the same Port or offshore location. It will not be possible to submit the Departure report if the name of the port or offshore location is different from that in the Arrival report.

In addition to Position, Arrival and Departure reports, other relevant periodic reports including Noon Reports, Monthly Reports, and Quarterly Reports are to be filled as per the formats in the company’s reporting infrastructure for ships.

The quantity of fuel bunkered, as stated in the Bunker Delivery Note (BDN), is to be checked by gauging all fuel tanks on board, prior to and after the completion of Bunkering, applying the appropriate correction factor to density for temperature, and obtaining quantities in Metric Tonnes before and after Bunkering. The ship’s figure of fuel Bunkered is the difference between the fuel quantity before and after Bunkering.

The ship’s figure is regarded as the authoritative quantity of fuel bunkered and is the quantity entered by Ship’s staff in the Departure Report

Written records showing the Soundings before and after of all fuel tanks and details of the calculations showing ship’s figure in Metric Tonnes of quantity Bunkered are to be retained on board.

The temperature of the fuel in tanks is to be obtained from tank temperature gauges if provided or by using portable temperature gauging devices if provided. If no gauges are provided, the temperature of the fuel in tanks may be determined by measuring the temperature of the tank sides using an infra-red thermometer or estimated by taking the weighted average of the best estimate of the temperature of the fuel in tanks before bunkering and of the fuel bunkered in each tank.

The density of fuel bunkered is to be obtained from the BDN.

The density of co-mingled fuel in tanks is obtained by calculating the weighted average of the density of the fuel remaining in the tanks before bunkering and of the fuel bunkered in each tank.

Related Read: Procedure for Bunkering Operation on a Ship

The density of fuel should be corrected using an appropriate temperature correction factor obtained from ASTM Petroleum Table 54B or equivalent or computer software incorporating these tables or the formula: Corrected density = Density (in the air) at 150C X [1- {(T0C – 150C) X 0.00065}], where T0C is the temperature of the fuel in degrees Celsius.

In case of bunkering from the barge, all tanks on the barge are to be sounded before and after Bunkering by a responsible officer. Barge tanks are also to be checked for the presence of free water. A written record is to be made of the results of these soundings and free water checks.

The Chief Engineer is responsible for checking the fuel quantity bunkered.

Fuel quantity (in Tonnes) in all bunkered tanks is to be re-checked 24 hours after completion of bunkering or just prior to commencing use of the newly bunkered fuel (if it is to be used within 24 hrs of bunkering) to account for possible settling of fuel due to air injection while bunkering.

Related Read: Malpractices In Bunkering Operations Seafarers Should Be Aware Of

Prior to entering ECA, fuel oil changeover to low sulphur oil has to be started. The time for starting depends on how much volume of fuel is used in the system, you calculate how much time it will take for the full system to change over into low sulphur fuel. Logbook entries have to be made accordingly, recording volume of low sulphur fuel in tanks, date, time and position of the ship when the fuel oil changeover was completed. It is a requirement that changeover procedures are available in the proper written format.

Distances travelled, are to be measured over the ground, between Departure and Arrival and are to be reported in Position and Arrival reports. Distances travelled over the ground may be taken from ECDIS or GPS, or from manual measurement on Chart. Distances travelled through the water are also to be reported in Position and Arrival reports and are to be taken from the (water) speed log.

Distances that may be travelled between Arrival and Departure reports (such as, during transit from Anchorage to Berth or when shifting between terminals within a Port) are not required to be reported in Voyage reports but should be noted in the Deck Log Book.

Related Read: Why Nautical Mile and Knot Are The Units Used at Sea?

‘Hours underway’ from the last berth at the port of departure to the first berth at the port of arrival is calculated from the departure and arrival times (GMT) and dates (GMT) recorded in Departure and Arrival reports.

Times and dates are to be recorded in GMT as well as SMT. Time spent between the first berth at the port of arrival to last berth at the port of departure is considered to be time spent in port. This includes periods at berth, at anchor and the periods spent manoeuvring within the port.

Fuel flow meters, fixed tank gauging devices and temperature measuring devices/gauges are to be checked and calibrated for accuracy at intervals as recommended by the manufacturer / as stated in the PMS. Certificates of calibration are to be issued post these checks and retained on board.

The validity of calibration certificates will be checked during the annual internal audit.

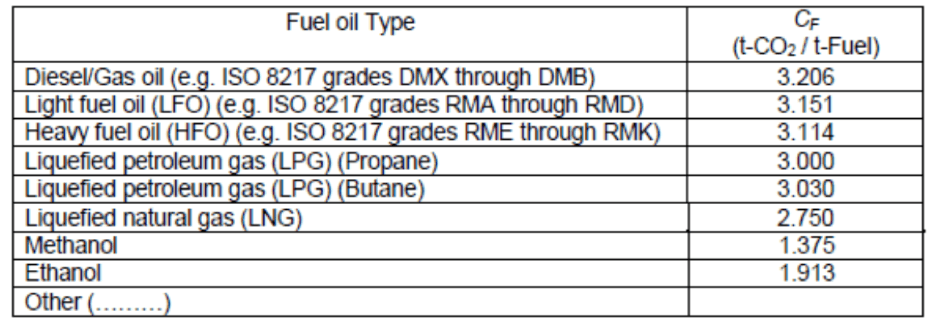

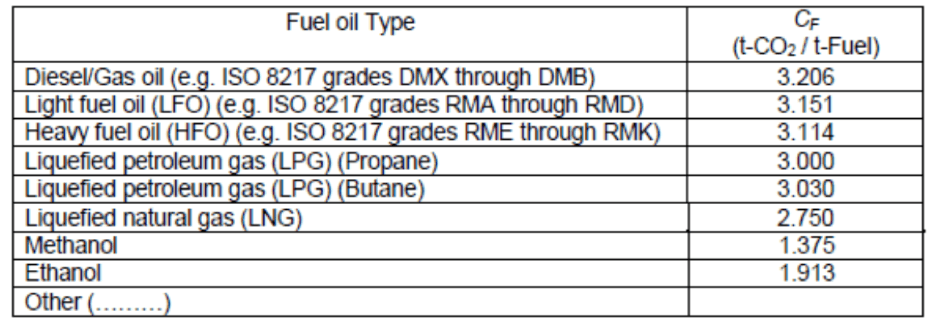

CF is a non-dimensional conversion factor between fuel oil consumption and CO2 emission in the 2014 Guidelines on the method of calculation of the attained Energy Efficiency Design Index (EEDI) for new ships. The annual total amount of CO2 is calculated by multiplying annual fuel oil consumption and CF for the type of fuel.

Related Read: 20 Ways for Seafarers to Reduce Their Carbon Footprint on Ships

From 2019, every ship above 5000 gross tonnages has to collect certain information about the ship and its fuel and submit to IMO. This includes Ship Particulars, the period of the calendar year for which the data is being submitted, fuel oil consumption in metric tonnes, fuel oil type and methods used for collecting fuel oil consumption data, distance travelled and hours underway.

This data provided by the ship will help them to summarize the fuel oil consumption of all the ships and will be used to research and find out ways to reduce emissions and pollution.

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of The Marine Learners. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and The Marine Learners do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and The Marine Learners.

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.