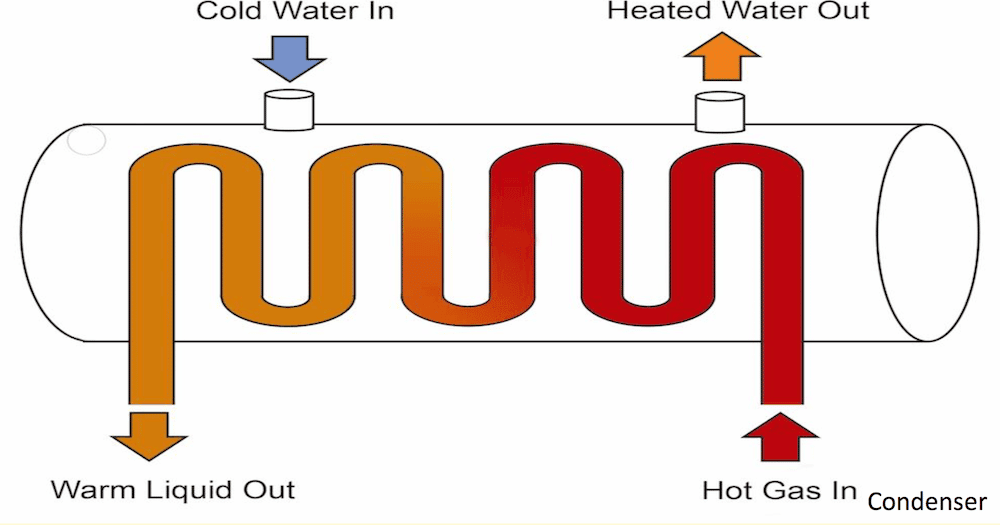

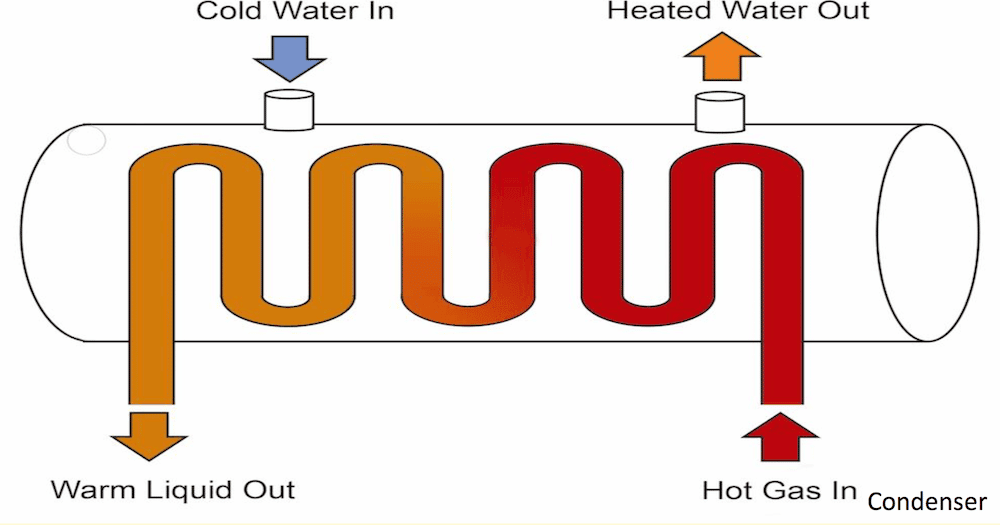

Heat exchanger is an equipment which reduces the temperature of a medium by transferring temperature of that medium to another, when both the mediums are separated by a solid membrane or wall like structure. For efficient operation, the surface area of the wall which separates the two mediums is maximized, simultaneously minimizing the flow resistance of the fluid.

Exchanging of heat in a heat exchanger can be in between- liquid and liquid, gas and liquid, liquid and gas etc. For heat transfer basically three patterns of flow are used for construction of a heat exchanger.

Opposite Flow : Primary medium (to be cooled) and secondary medium (which is cooling the primary medium) enters in the heat exchanger in the opposite direction to each other.

Cross flow : Primary and secondary medium enters in an exchanger perpendicular to each other.

Parallel flow : Primary and secondary medium both enter the heat exchanger parallel to each other.

Each and every system in a ship is interlinked with each other in some way or the other. Even if one system fails, vessel can come to a standstill.

Heat exchanger plays an important role for efficient working of different systems, which include-

1) Propulsion Plant:

– Main propulsion plant consists of different sub system for running of main engine like lube oil system, jacket water system (open or closed system), fuel system etc.

– While generating energy all these systems gets heated up and the temperatures are controlled by the use of heat exchanger in the system.

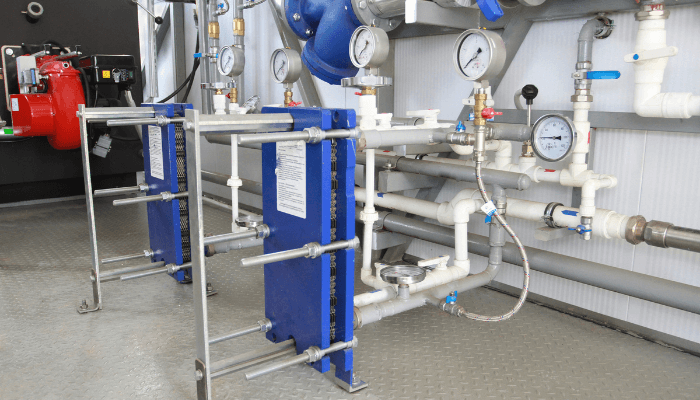

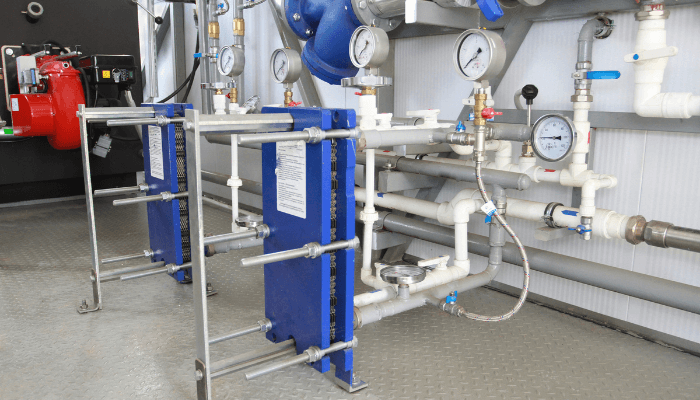

– Heat exchangers normally used in main propulsion system are – Shell and tube type and plate type heat exchanger.

2) Auxiliary Power Generation System:

– Auxiliary power generation system is similar to the main propulsion system, except that the power is generated in terms of output.

– Shell and tube type, plate type and plate fin type heat exchanger are generally used

3) Starting Air System:

– High pressure air is produced in the compressor which is further cooled in inter-cooler, which acts as a heat exchanger

– Shell and tube type exchanger is popularly used for this purpose.

4) Fuel injection system:

– For proper atomization, fuel is heated up in a heater with heating medium as steam. Shell and tube type heater is used for this purpose.

– For reducing Sox emission from propulsion plant, combustible fuel is mixed with a spray of water, for this direct contact heat exchanger is used.

5) Refrigeration System:

– In refrigeration system, for meat room, fish room and vegetable room, evaporator acts as phase change heat exchanger.

– Shell and tube type unit is used for condenser unit in refrigeration system.

6) A.C system:

– For maintaining the temperature, phase change heat exchanger unit is installed as evaporator.

– Condenser unit is normally shell and tube type exchanger.

– For generating fresh water, sea water condenser and jacket water evaporator is used. Both are types of heat exchangers.

– Shell and tube type and plate type heat exchangers are normally used for this.

8) Steam Turbine Unit:

– If a ship consists of a steam turbine or turbine generator, normally spiral heat exchanger is used for heat transfer.

Apart from the above mentioned places, there are several other applications where heat exchangers are effectively used for the smooth running of the ship.

If you liked this article, you may also like to read Types of heat exchanger in ship.

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.