As a seafarer on a merchant ship or as a ship manager/owner of a vessel, one of the biggest nightmares is that of any kind of oil pollution accident on a ship.

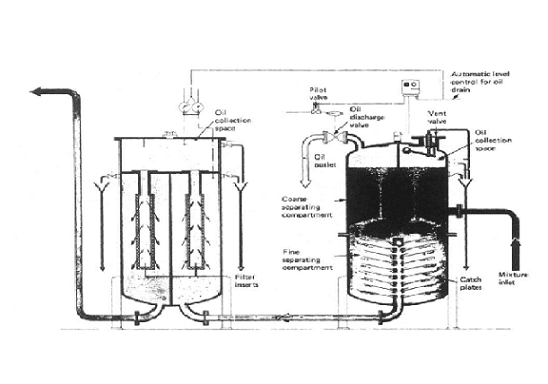

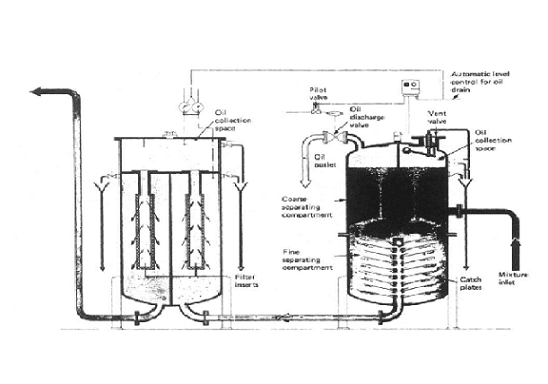

A ship produces oil and water mixture on a daily basis which needs to be separated from each other before discharging the dirty water out of the ship using equipment such as an oily water separator.

MARPOL has a regulation under ANNEX I, which limits the oil content in the bilge water that a vessel can legitimately discharge into the sea. It is now a requirement for all vessels to have an oil discharge monitoring and control system along with oil filtering equipment known as the Oily Water Separator (OWS).

A ship engineer may work with 5-10 different makes of marine engines, but he/she is more likely to encounter many more types and makes of OWS in his/her career span. Even for PSC inspectors and surveyors, an oil water separator (OWS) has always been a preferred choice of machinery on the ship for inspection. Hence, it is imperative to know and understand the basics of oil and water separator design and how an oil and water separator works.

Related Reading: How to operate an oily water separator?

As the name indicates, the function of an oil-water separator is to separate the maximum amount of oil particles from the water to be discharged overboard from the engine room or cargo hold bilges, oil tanks and oil-contaminated spaces. As per maritime regulations, the oil content in the water processed from the OWS must be less than 15 parts per million of oil.

Related Reading: What is Oil Discharge Monitoring and Control System?

As per Annex 1 of MARPOL under regulation four specified under paragraphs 2, 3, and 6, any direct discharge of oil or oily water mixture into the sea shall be prohibited. The regulation further explains how an oily water mixture can be treated on board and can be discharged out at sea:

For a ship with 400 GT and above, discharge of oil mixture can be done under the following conditions:

1. The ship is en route;

2. The oily mixture is processed through an oil-water separator filter meeting the requirements of regulation 14 of this Annex;

3. After passing the oil-water separator system, the oil content of the effluent without dilution does not exceed 15 parts per million;

4. The oily mixture does not originate from cargo pump-room bilges on oil tankers

5. In an oil tanker ship, the oil-water mixture is not mixed with oil cargo residues

When the ship is plying in the Antarctic area, any discharge into the sea of oil or oily mixtures from any vessel shall be prohibited.

Related Reading: What factors affect separation in oily water separator?

The OWS must only be operated by officers who are familiar with the equipment and who are directly supervised by the Chief Engineer, who bears sole responsibility for its maintenance and operation. When the equipment is not in use, the Chief Engineer is responsible for ensuring that a procedure is in place to lock it out to prevent unauthorized operation with keys in possession of the Chief Engineer.

It should be emphasized that sailing from a port without a functional OWS is unlawful and that appropriate spares for the unit must be carried onboard. The Critical Equipment section contains information on MARPOL equipment.

Related Reading: How Good Bilge Management Practice Help Improve OWS Performance?

A freshwater inlet connection is also provided to the filter unit to clean and flush the filter. This is usually done before and after the operation of an oil separator unit.

Related Reading: 20 Important Factors For Oily Water Separator Operation On Ships

A small pipe connection of fresh water can be provided to the OCM unit for flushing. Whenever this line is in use, an alarm is sounded and recorded in the OCM log, ensuring a record to check the discharge valve was shut during this period.

As in most shipping companies, the OWS is meant to be operated only by the chief engineer, and the training levels on OWS systems for other crew members are found to be very low. The ship operators should ensure onboard guidance and training are included in the training schedule of the ship.

Several factors affect the separation of oil from bilge water, such as :

Due to the general difference in weight between an oil particle and a particle of water of similar volume, the force exerting on an oil globule to travel in water is proportional to the difference in weight.

A globule’s resistance to mobility is determined by its size and the viscosity of the fluids in which it is contained.

Thus, a high rate of separation is often favoured by

2. Pumping Consideration

An important consideration is to minimize any disintegration of large-sized oil droplets in the feed oil for a separator, which may be greatly impacted by the type and rating of the pump used in the process.

Many bilge pumps are centrifugal, and they are often employed as supply pumps for the separator.

Thus, when the supply is turned on, it creates tiny oil droplets that scatter throughout the water, posing a major threat to the separation’s performance.

A positive displacement pump, such as a slow-running double vane, screw, reciprocating, or gear pump, allows the separator to work considerably better since it does not generate a significant number of tiny droplets. Pumping after the separator may result in a discharge with a concentration of less than 15 ppm without the need for 2nd Stage filters.

As a result of the preceding two arguments, it is clear that even if the separator is properly maintained and operated, the following causes might result in the separator malfunctioning:

Numerous traditional oily water separators cannot split stable emulsions and remove colloidal particles suspended in the water phase. This often leads to equipment failure due to insufficient oil separation below 15 parts per million (ppm) or blockage from excessive solids. An effluent with an oil content of not more than 15 parts of oil per million parts of water by volume may be produced via a combination of a bilge separator, a coalescer, or other techniques.

Recirculation facilities should be installed after and next to the stopping device’s overboard outlet to permit testing of the 15 ppm bilge separator system, including the 15 ppm bilge alarm and the automated stopping mechanism, with the overboard discharge locked.

The influence of bilge water containing cleaning chemicals is one of the primary reasons for oily water filtration system failure. Cleaning fluids based on detergents may form chemically stabilized oil emulsions that cannot be separated on board ships just by gravity. Avoiding the use of surfactant-based cleaning chemicals is the greatest strategy to optimize the effectiveness of oily bilge water separation equipment.

To remain in excellent operating condition, an oily water separator must be properly and routinely maintained. When these devices are not drained and cleaned consistently, oils and other debris clog them and render them inoperable. This may result in oil levels in the discharged water exceeding the effluent limitations mentioned.

Oily water separator models that are elevated above the ground are considerably simpler to clean since everything is easily accessible. This is because there are no restricted places, and plates may be removed, cleaned, and changed. All forms of above-ground structures may be maintained from the ground. Additionally, solid waste may be conveniently evacuated via a big hole at ground level.

When employing a below-ground oil-water separator, it is essential to adhere to a tight maintenance plan. It is more probable that you will overlook cleaning the unit since it is buried in the ground. These are the oil-water separator maintenance methods to follow.

After a month of usage, do the following checks and cleanings on the inlet area:

The media plates will need to be cleaned once all of this has been completed. They may be cleaned either inside or outside the unit. Insert a low-pressure hose in between the plate gaps on the plate packs to clean them without dismantling them. Remove any debris drained from the plates by draining it down the hopper outlet.

When cleaning the plates outside of the oil-water separator, use a low-pressure hose to rinse them off, taking particular care not to get any of the discharge on the ground where it might contaminate groundwater. Getting rid of the accumulated sludge and oil is the only thing that’s required.

To make sure that the tank is safe, check it for damage and fix the internal coating if it needs to be done. Simply re-insert the plate packs into the separator in the same order as they were removed in order to restart the machine. Make sure that they are firmly attached to the device so that they don’t fly away when it restarts. Depending on the unit’s use and the quantity of oil and other debris collected, maintenance should be performed on a regular basis by a skilled specialist.

References

Introduction to Marine Engineering- By D.A Taylor

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of The Marine Learners. Data and charts, if used in the article, have been sourced from available information and have not been authenticated by any statutory authority. The author and The Marine Learners do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendations on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and The Marine Learners.

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.