A rescue boat was being recovered after normal deployment and maintenance. At one point the davit operator tried to stop the raising operation but the hoist button, emergency stop and limit switch circuits all failed to stop the winch from hoisting. Thankfully, personnel were able to disconnect the electrical power via the 480V main breaker before the boat contacted the davit, avoiding serious damages and injury to personnel.

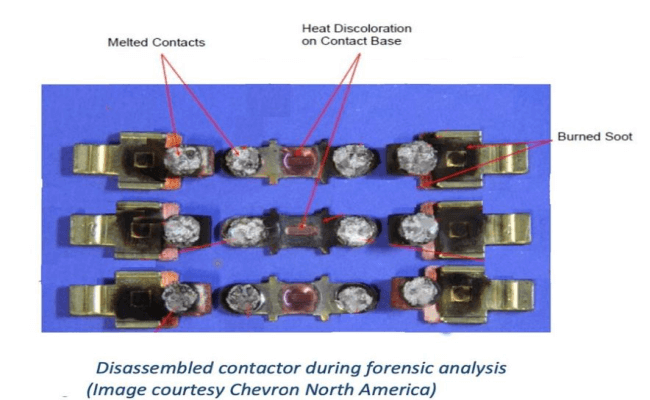

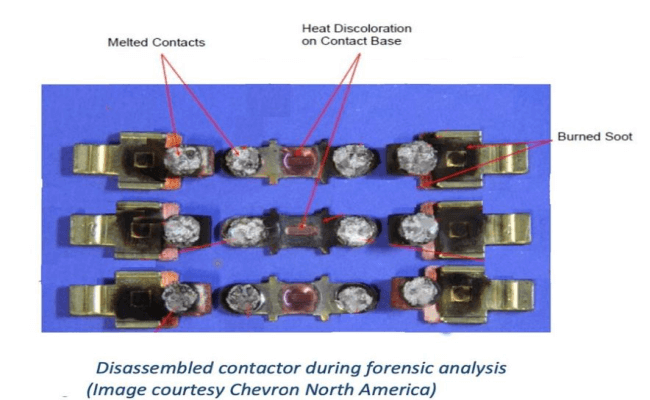

Metallurgical analysis carried out after the event found that the failure occurred when the winch control contactors fused together due to the duty rating being exceeded. Additionally, it appears that the contractors were not rated for intermittent cycling (repeated start/stop sequences) of the winch. After an inspection on other installations, several contactors showed evidence of overheating and indications of welded and scorched contacts were found.

Intermittent cycling is a common practice during the recovery of a lifeboat or rescue boat into the stowed position. For example, a winch may be cycled after the boat has cleared the water to verify the release gear condition. Or again, it may be cycled as the boat approaches the davit guides/stops to reduce momentum. While intermittent cycling is commonly employed for a safe recovery process, it may in fact cause power to exceed the design and duty ratings of the electrical components.

Lessons learned

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.