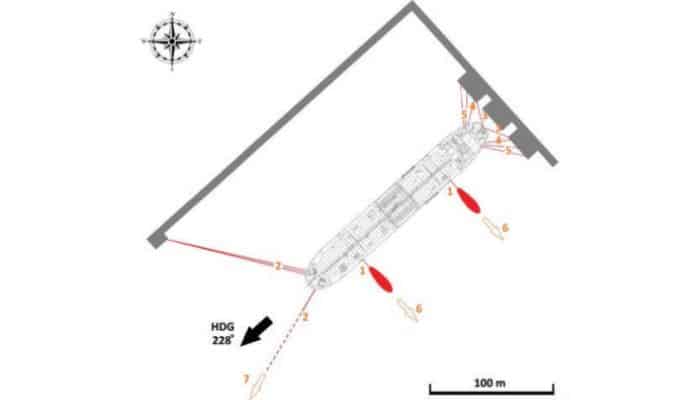

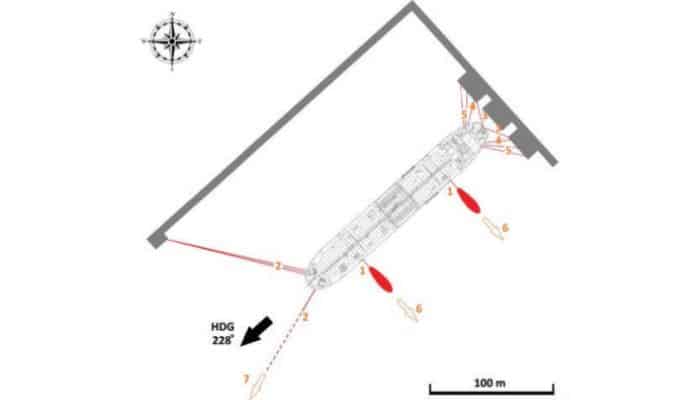

A tanker in ballast was departing berth under pilotage with the assistance of two tugs on the port side.

The vessel was berthed ‘Mediterranean style,’ with lines running astern to the pier and to starboard on another pier in combination with an anchor on the port side, as shown in the diagram

The Master and the pilot agreed on the unberthing sequence as follows:

1. Both tug boats to be secured port side fore/aft.

2. The three mooring lines from the starboard side forecastle deck to be released and the anchor to be engaged.

3. The two mooring lines not under tension at the aft bitts to be released from the pier and collected through the stern centre chock.

4. The two aftermost ropes to be released and collected on their drums.

5. The four remaining ropes aft (two starboard and two port) to be released and collected on their drums.

6. Both tug boats to pull the vessel sideways to clear her from the pier.

7. Heave up the anchor

When the three lines forward on the starboard side were released and brought on board (step 2 in the plan), the vessel began to yaw to port due to a light breeze on the starboard bow. This may have caused some consternation on the bridge. Having no view of the afterdeck, the Master asked about the distance of the vessel’s stern from the berth. The officer replied it was about seven metres.

The Master then requested the Officer astern to engage all six remaining lines (three from each side) and bring them on board. Meanwhile, the two tugboats on the port side were already beginning to pull the vessel to port. With so many lines aft to bring in at once, the operation was not easy at the aft mooring station. One line to starboard remained taut as the others were being brought aboard.

Before the tension could be released, the line parted and whiplashed on deck. The end of the broken line hit a crewmember on the back and he collapsed. Despite resuscitation efforts both onboard and later on shore, the victim succumbed to his injuries.

The official investigation found, among other things, that the stern line had probably failed at a tension that was less than the indicated amount on the Test Certificate, even though it was in good condition. Upon further investigation the Test Certificate was found to be non-authentic.

Lessons learned

Reference: The Nautical Institute

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.