Tankers have been one of the oldest types of merchant ships; the need for these vessels arising due to heterogeneous distribution of natural oil reserves and liquid chemicals around the globe.

The most common types of tankers operating at sea are oil tankers. While it may seem that oil tankers generally carry oil, the fact has quite more to it, if understood in detail. Which brings us to the need to understand that since there are different grades of oil (depending on the levels of purification), oil tankers have been designed separately and specifically to carry different oil types.

It is important to have a brief look into the history of oil tankers, especially to understand the dynamics of the oil market and relate its influence on the sizes of oil tankers used in different eras.

The size of oil tankers had seen a rapid increase in the mid-seventies due to abundance in oil trade, and as a result, for the first time, tankers of deadweight in the ranges of 100000-200000 lakh metric tonnes were constructed in Japan to be able to carry more quantity of oil in a single voyage, and hence reduce the freight costs for more profits.

But in the late nineties, due to the skyrocketing of oil prices, the quantity of oil being traded by sea had considerably reduced, hence almost putting an end to building of ULCC (Ultra Large Crude Carrier) and VLCC (Very Large Crude Carrier).

These tanker ships can be categorised into different types, based on two criteria – Size and Type of cargo.

Based on size, oil tankers have been categorised into the following types:

The classification of oil tankers based on type of cargo is not a clear and fixed classification, because these are terms used by different nations and organizations based on their ease of nomenclature.

Some of the most commonly used types of tankers are listed below. We will also understand, how different types of tankers are designed to carry a specific type of cargo.

Related

These tankers are designed to carry hydrocarbon products like kerosene, gasoline, paraffin, etc., chemical products like ammonia, monomers, etc., wines, molasses, etc. Though, now, chemical tankers, LPG and LNG carriers are classified differently due to significant uniqueness in their designs as compared to petroleum product tankers. Product tankers are usually short range coastal tankers, hence are smaller in capacity. They carry products from processing plants to distribution units.

Crude oil carriers are designed to transport crude oil from rigs to processing units (refineries). Since the amount of crude oil extracted from offshore drilling platforms is considerably larger than the amount of products extracted from it, crude oil tankers are required to be of sizes larger than product tankers. Sizes like that of VLCCs and ULCCs are only used for crude oil tankers, and these are usually ships that ply on long range voyages.

Chemical products like ammonia, palm oil, vegetable oils, monomers, caustic soda, methanol, etc. These ships have considerable uniqueness in their design, owing to the special requirements depending on the type of cargo. We will discuss these aspects in a later part of this article when we discuss design of different tankers. Chemical tankers are usually categorised into three types:

Type 1: These tankers are designed to carry products that are associated with severe environmental and safety related hazards. Such products require maximum prevention of spill.

Type 2: They are also designed for hazardous products, but the extent of severity for these products is lesser as compared to Type 1.

Type 3: These are designed to carry chemical cargo that requires moderate standards of containment and pose moderate environmental and safety hazards.

These ships actually fall under the category of liquefied gas carriers, and a large number of them are in service to carry liquefied gases in bulk. The number of ships that carry Liquefied Petroleum Gas (LPG) is however, much more than the number of ships carrying Liquefied Natural Gas (LNG). We shall look into some of their design aspects in another article to understand what makes them very unique from other types of tankers.

With an overview of the different types of tankers and each of their functionality, we will now look into the important design aspects of each of them. It is important for you to keep in mind from now, to observe how every design decision that is made, is directly or indirectly related to a functional aspect of the ship. We will relate every design aspect with the inter-related functional or market-based reason that governs it.

Related:

Important points for efficient tanker ship operations

The most notable feature of any ship is the geometry and form of its hull. The design of an oil tanker is a weight-based design, which means, the dimensions of an oil tanker would be governed by the weight of cargo to be carried. (The other type of design is volume-based design, where the dimensions of the ship are determined by the volume of cargo spaces required in the vessel. For example, container ships.)

Since the weight of oil to be carried in a single voyage is to be maximised, it is preferable to have maximum spaces for cargo oil tanks. Also, oil tankers ply at very low speeds since the cargo is not perishable. Both the aforementioned factors come together to determine the full-form shape of an oil tanker. In other words, an oil tanker would have higher Coefficient of Buoyancy as compared to ships of finer hullform (e.g. container ships).

Note, in Figure 2, the fullness of the hullform of an oil tanker at the forward part, compared to that of a container ship. Unlike a streamlined fine hullform, this shape caters well to low speeds and maximum cargo capacity. However, the blunt forward shape gives rise to eddy and wave-breaking at the forward part, resulting in increased wave-breaking and eddy-making resistance.

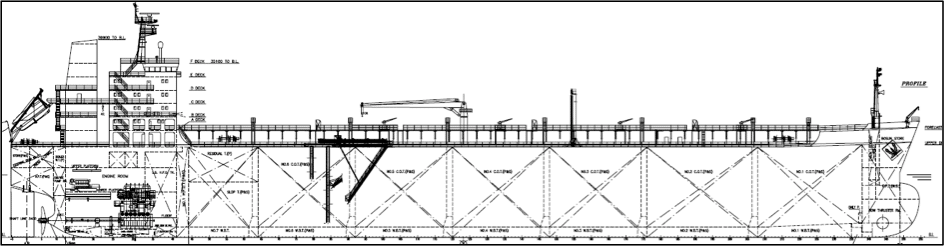

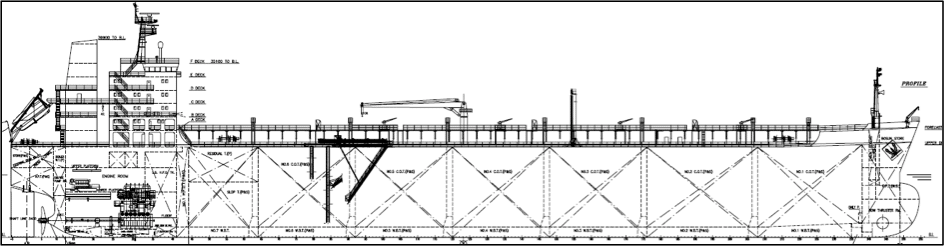

The most important design drawing that is to be studied in order to identify the design of a ship, is its General Arrangement Drawing. Figure 3 illustrates the profile view of an oil tanker’s general arrangement. It basically shows the arrangement of all the spaces within the ship, and gives a frame-by-frame location of every space, bulkheads, and other primary structures.

Some of the design details of an oil tanker will be well understood by referring to the profile view. The cargo oil tanks (C.O.Ts) are usually equally sized, and the dimensions of each are decided by the designer in the initial stage of design, depending on the total weight of oil to be carried by the ship. The access to each COT is separate, and is provided by means of rung ladders or hoist-able steps from the main deck.

The main deck of an oil tanker is usually mounted with a network of pipelines that are used to load and unload cargo oil to and from the ship. Flexible hoses are attached to the pipelines for completion of the process.

‘Guess Why’ – Bulk carriers have deck-mounted cranes to load and unload cargo. Some container ships also have deck cranes for loading, unloading and stowage of containers. But, in-spite of carrying liquid cargo, why do most oil-tankers have at least one deck crane. Why? Try to reason it out, till we find the answer at some later point in the article.

The engine room and superstructure, as usual, are located at the aft. But, one notable feature in oil tankers, that is not found in other types of ships is the pump room, that is usually located just forward of the engine room. The pump room houses all the pumps required for cargo oil loading and discharge.

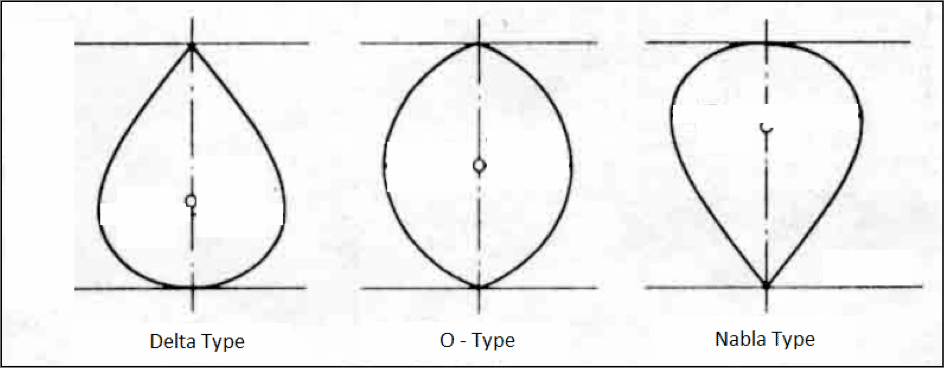

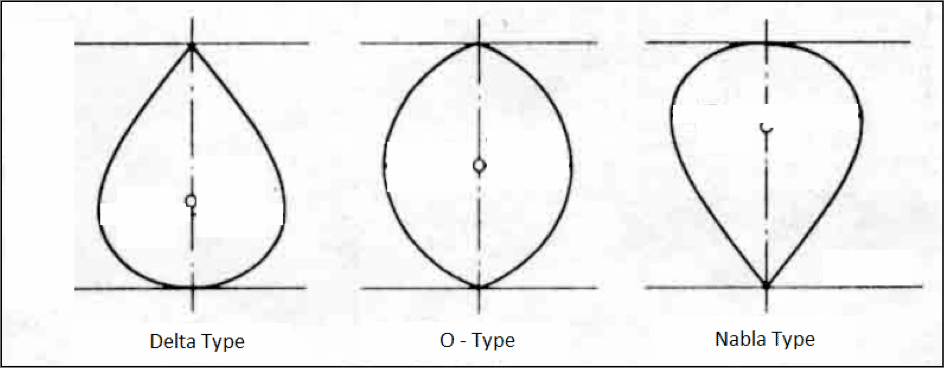

Today, all tankers are equipped with a bulbous bow, so as to increase the power efficiency of the ship. Though these are slow speed ships, a bulbous bow reduces the wave making resistance considerably. However, the shape and geometry of the bulb differs significantly from those of high speed ships. We will understand how and why.

There are three basic bulb shapes, when looked from forward to aft of the ship, as shown in Figure 4. The Delta type bulb has more volume concentrated at the lower half, than the upper half. This property makes it advantageous to be used in ships that have frequent changes in waterline, as more concentration of bulb volume at the lower portion ensures bulb immersion for a larger range of waterlines and loading conditions.

The O-type bulb has maximum volume concentrated at the center. This is used for most ships that require a cylindrical bow shape, for example- bulk carriers.

The Nabla type bulb is almost shaped like that of a tear-drop, with more volume concentrated at the top. This shape of bulb is preferred in ships that are to be equipped with exceptional sea-keeping abilities, for example – warships.

Which of the three above types do you think is most preferred for an oil tanker? In order to answer that, we will need to look into the functional aspects of an oil tanker. Most tankers carry cargo only on one leg of their voyage, and the other leg is usually made on ballast. The ballast waterline of ships is different from the fully loaded waterline, though the difference is less. But, this frequent alteration in waterline requires the bulbous bow to be immersed at all loading conditions.

Hence, as quite apparent now, tankers are equipped with delta-type bulbous bow. Bulbous bow in a tanker is also advantageous because it acts as a ballast space to control the trim of the vessel in light conditions, thus reducing bow slamming.

The structural design of oil tankers vary according to the type and size of the tanker. To understand them, we will study their midship sections in detail.

Most product tankers and coastal tankers are small in size, and are single hull designs, that is, they do not have a double bottom. However, recent MARPOL (Marine Pollution) Rules require tankers over 120 m length to be double hulled irrespective of the type of cargo.

Related:

Single Hull vs. Double Hull Tankers

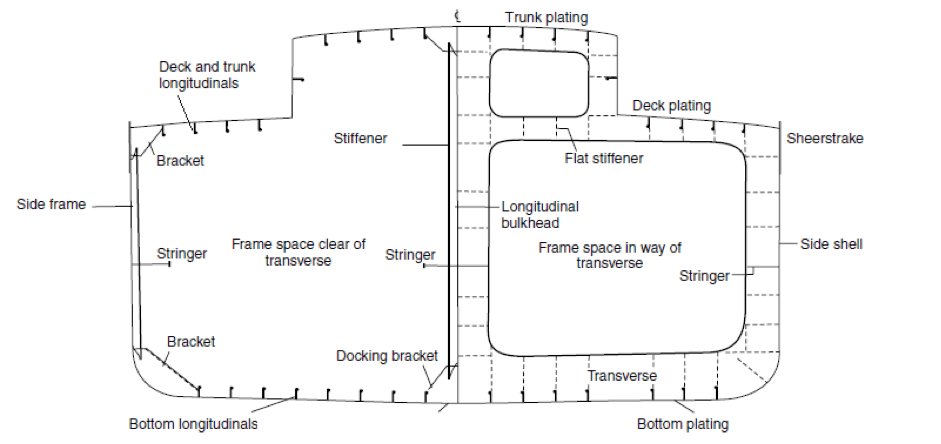

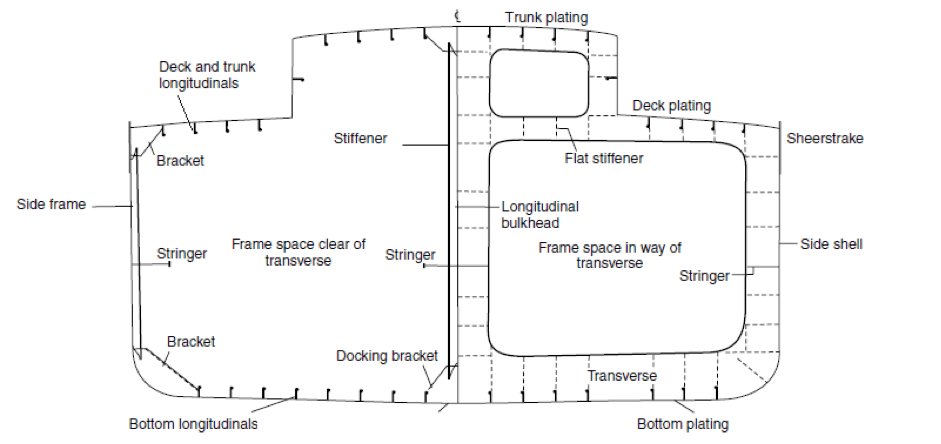

A trunk is a raised structure that runs along the length of these ships, and provides space for access to the cargo oil tanks. The bottom shell, deck plating, and trunk plating are longitudinally framed to add to the longitudinal strength of the ship. The side shells are transversely framed, and the reason behind that is a very interesting design aspect:

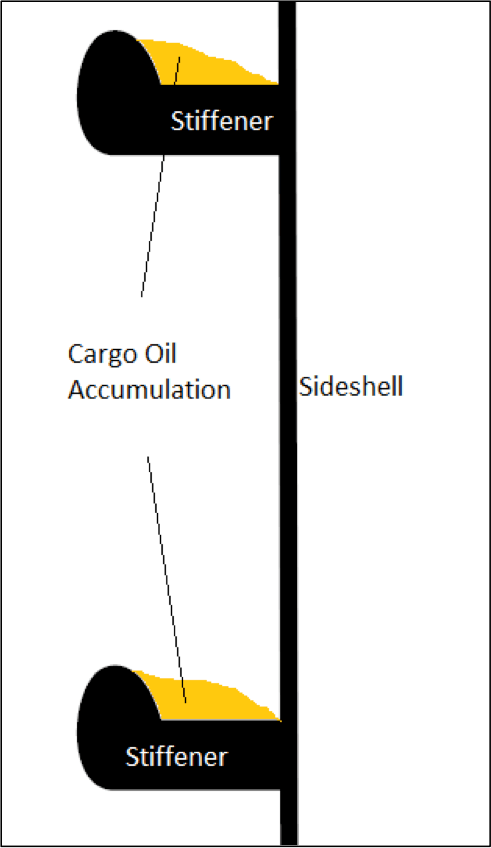

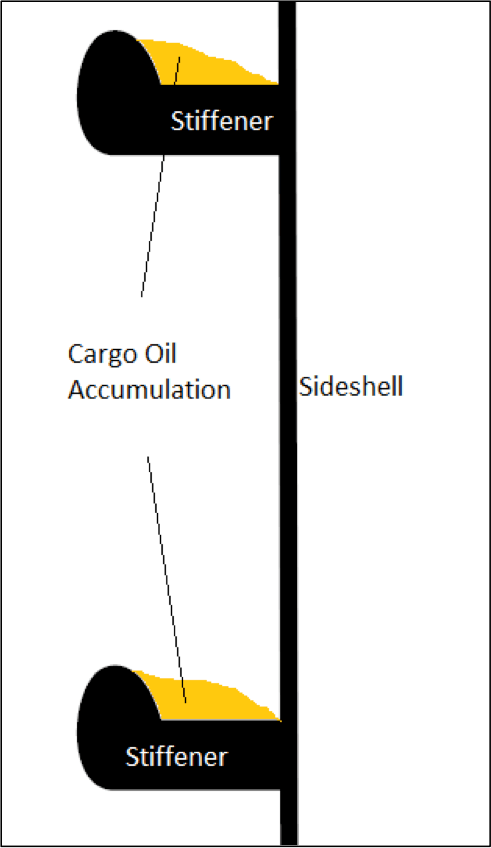

If the side shells were longitudinally framed, then cargo oil can accumulate on the space between the stiffeners and the side-shell even after the oil is pumped out (because pumps do not discharge the entire volume of oil, and some amount of oil always remains in the inaccessible corners of the tanks). This phenomenon is shown in Figure 6 below, and it has two major effects: One, it leads to contamination of cargo. Two, prolonged accumulation leads to corrosion of the stiffeners.

The stringer on the side-shell is usually added to reduce the depth of the transverse frame, which would otherwise be much higher and reduce the useful volume of the cargo oil tank.

Brackets are used to create a path for flow of stress from the side shell stiffener to the deck longitudinal and bottom shell longitudinal. A deep web frame (shown at the right half of Figure 5) is usually placed at every three or four frame spaces. It is a continuous structure that runs along the deck plating, side shell plating, bottom plating and centerline bulkhead. Horizontal stringers run through these deep webs, and help in reducing the depth of the webs to save cargo space. The span of each longitudinal stiffener is equal to that of three or four frame spaces, that is, both ends of each longitudinal stiffener (on deck plating and bottom plating) is welded to subsequent web frames.

All oil tankers of length above 120 m are required to be double hulled, as per MARPOL rules. Panamax, Aframax, Suezmax, VLCC and ULCC tankers are all double-hulled. The primary reason for providing two hulls is to prevent the contact of cargo oil with the external environment in case of any structural damage to the hull.

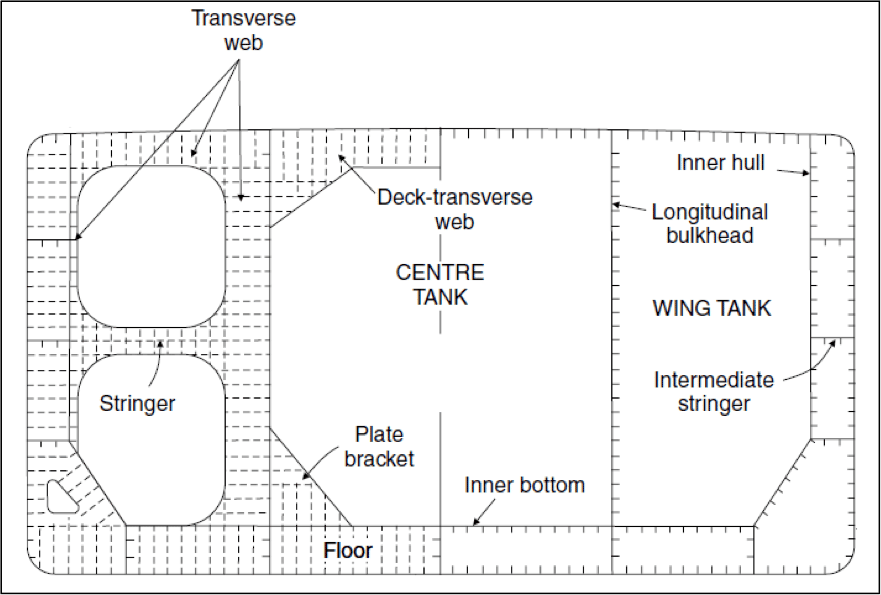

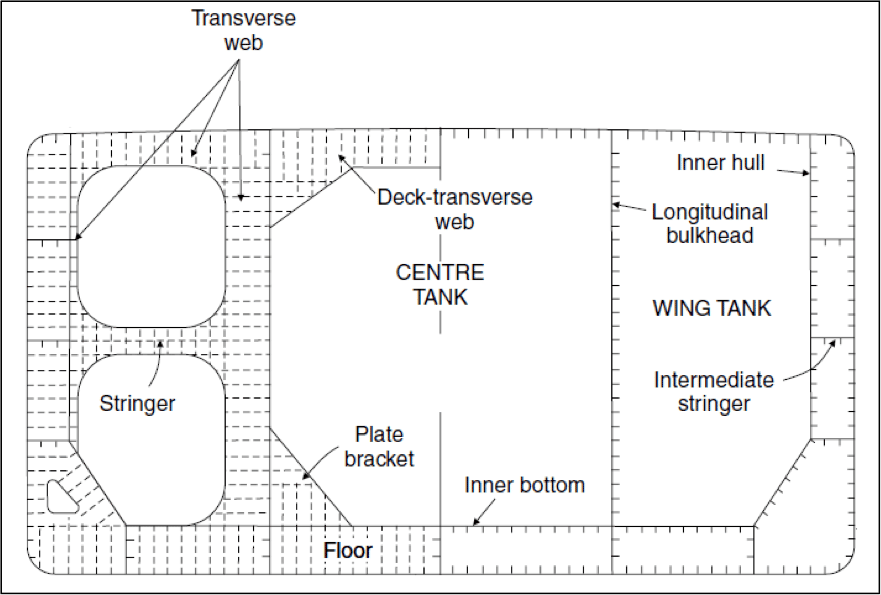

The above figure is the midship section of a double hull tanker. The right half of the drawing shows an ordinary frame, where the outer and inner hull plates are longitudinally framed. The centre tank is used for storage of cargo oil, and the wing tanks or segregated ballast tanks (SBTs) are used for carrying sea water ballast. The SBTs are epoxy coated so as to prevent corrosion. Do observe that the longitudinal stiffeners on the wing tank longitudinal bulkhead are placed towards the wing tank, and not the centre cargo oil tank. Why? In order to prevent oil accumulation on them. The double bottom spaces are also used for water ballast, and the stiffeners on the inner bottom plating are always towards the double bottom space.

A deep transverse web frame (left half of the above figure) is given at every three to four frame spaces in order to provide transverse strength to the ship. The longitudinal stiffeners are welded to these web frames. Stringers are provided on these transverse webs to provide further strengthening.

Today, irrespective of the classification society certifying the design of a tanker, the structural design of double hull tankers is done according to The Harmonised Common Structural Rules (CSR) for Tankers, by IACS.

Since tankers are low speed vessels (average maximum cruising speed is 15.5 knots), and are not restricted by space constraints, they can afford to be run by large slow speed marine diesel engines. These engines occupy more space than high speed marine diesel engines, but provided more shaft efficiency, and gearbox losses are eradicated since the RPM of the engine is same as that of the propeller. Usually, large diameter and low RPM propellers are used for more propulsive efficiency.

Oil tankers have a number of systems that are unique to its operation. We will discuss the most important ones in brief.

Related:

Understanding crude oil washing operation on ships

Important points for committing cargo quantities in tanker ships

Answer to ‘Guess Why’: Most oil tankers are provided with at least one deck-crane so as to handle the cargo oil hoses during discharge and loading of cargo oil, when the hoses are to be removed from stowage points and connected to the discharge manifolds on the ship’s deck.

To conclude, though this article does discuss about a lot of design issues and features of an oil tanker, the scope of this article is limited to a concept design stage. A detailed study on tanker design can be done by studying on not only the naval architectural aspects, but also an in-depth study of every system and their operation and interaction with other systems on board.

Further, a good designer should also be well read in all the MARPOL and HCSR rules that govern the design of oil tankers today.

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of The Marine Learners. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and The Marine Learners do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and The Marine Learners.

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.