As the fuel prices go sky high, ships are using lower grades of fuel for saving its operational cost. The fuel used for burning in the auxiliary engine and main propulsion plant is normally heavy fuel oil. Along with other properties, the viscosity is an important property which determines the efficiency of fuel combustion and of the marine engine.

The viscosity of fuel oil depends on the grade of oil. If the viscosity of the fuel oil and its viscosity index are on the higher side, it would lead to more difficulty in achieving atomization state and poor combustion inside the engine cylinder.

Understanding the Important Definitions

Viscosity

In simple term, it can be defined as ‘resistance to the flow of the fluid offered by its internal layers due to internal frictions’. It is measured in centistokes (cst).

Less the viscosity, lesser the resistance to flow and the fuel can be easily atomized.

Viscosity index

It is an important factor in selecting any kind of oil, fuel or lube oil. It’s the measure of change of viscosity of oil with variation in temperature.

Since fuel oil is heated to achieve proper atomization, it should have proper VI. If it’s on the higher side, it will be difficult to alter the viscosity of oil by the heater.

Atomisation

It is the process of breaking the fuel particle into fine mist spray under high pressure to improve the surface area of contact of fuel and air for proper combustion.

Viscometer or Viscotherm

The viscosity of the marine bunker HFO fuel when supplied at 50 ̊deg C varies from 180cst to 380 cst. The fuel is heated and the viscosity of the fuel is reduced to 13~15 cst at the time of injection in the engine by means of electrical or steam heaters or both.

The viscosity to the high-pressure fuel oil pump has to be maintained approximately at 13 cst to achieve efficient combustion.

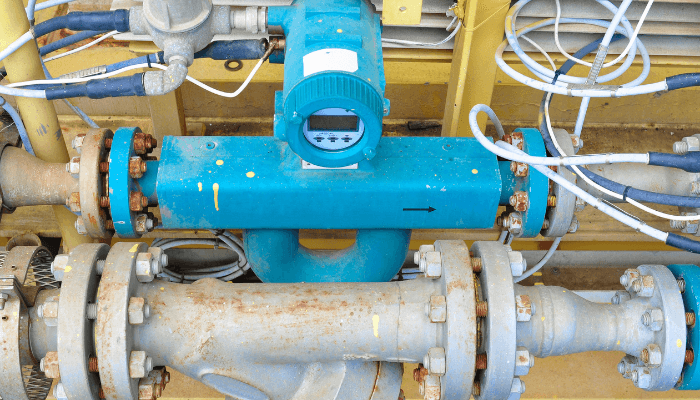

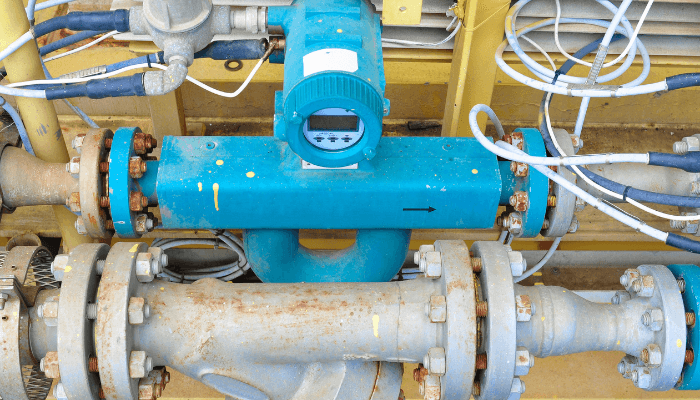

A viscotherm or viscometer is used to measure the viscosity of fuel oil at the fuel injection system of the engine.

Construction and Working of Viscosity meter

It consists of a capillary tube inside of which a gear pump is fitted which rotates at very slow rpm (say 40 rpm). There is an outside casing provided for the capillary tube.

When the oil passes through the casing, some part of the oil pass through the gear pump and its capillary, and some part of the oil passes over the capillary tube. Hence a flow difference occurs inside the casing. The oil inside the tube maintains a laminar flow and outside the tube maintains a turbulent flow.

The pressure difference between outside and inside of the tube is measured which is directly proportional to the viscosity of the oil. Hence oil viscosity is maintained.

Viscosity Controller

The viscosity controllers actact the controller of the 3 way valve from which steam is passed into the heater or bypassed from the heater as per the position of the control valve.

Construction and working

Normally pneumatic control system is used with bellows, flapper and nozzle. The output signal from the viscometer is connected to measured value bellow of the viscosity controller.

Another bellow is supplied with set point of the required viscosity and both the bellows are connected opposite to each other to complete a flapper nozzle control system. The output of flapper nozzle is the controlling signal of fuel oil heater 3 way valve.

A 3-way valve has 2 openings in which one is inlet and 2 are outlet. One outlet goes through the heater and one outlet is connected to a bypass line of heater.

When the set value and measured values are same, no signal is given to control valve and valve position remains same. More of the steam bypasses the heater.

When the measured value decreases, the output signal opens the control valve to steam side so that more steam is supplied and viscosity can be brought down.

It is important to have a better grade of marine fuel oil with proper viscosity index for maintaining proper efficiency of engine and to reduce wear down of the fuel injection parts.

You may also like to read- High Speed Centrifuge on Ship

We believe that knowledge is power, and we’re committed to empowering our readers with the information and resources they need to succeed in the merchant navy industry.

Whether you’re looking for advice on career planning, news and analysis, or just want to connect with other aspiring merchant navy applicants, The Marine Learners is the place to be.